Market Analysis and Insights:

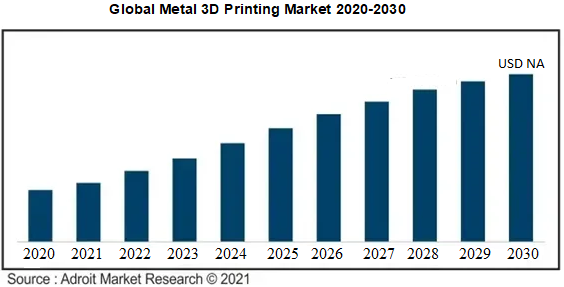

The metal 3D printing market was valued at USD 6.35 billion in 2022, and it is anticipated to rise at a compound annual growth rate (CAGR) of 24.5% from 2023 to 2030.

Numerous significant elements are propelling the metal 3D printing market. Firstly, the market is growing because metal 3D printing technology is being adopted more widely by many industries, including electronics, automotive, aerospace, and healthcare. This is due to the ability of metal 3D printing to reduce production time and costs while enabling the production of highly complex and customized parts. Second, because metal 3D printing offers better strength-to-weight ratio and design flexibility, its growth is being driven by the increased demand for robust and lightweight metal components in industries like aerospace and automotive. The creation of new metal alloys and enhanced printing techniques, among other technological and material developments, are also driving market expansion. Furthermore, government support and initiatives to promote the adoption of advanced manufacturing technologies, including metal 3D printing, are also contributing to market expansion. Overall, these driving factors are creating significant opportunities for the metal 3D printing market to grow in the coming years.

Global Metal 3D Printing Market Scope :

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2030 |

| Study Period | 2018-2030 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2030 | USD NA |

| Growth Rate | CAGR of 24.5 % during 2023-2030 |

| Segment Covered | component, technology, software, Application, printer type, Vertical, Region |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Arcam AB, a subsidiary of GE Additive; EOS GmbH Electro Optical Systems; Concept Laser GmbH; Renishaw plc; 3D Systems Corporation; SLM Solutions Group AG; Prodways Group; ExOne Company; Materialise NV; and Voxeljet AG, among others |

Market Definition

Using metal powders and a layer-by-layer method, metal 3D printing, commonly referred to as additive manufacturing, produces three-dimensional items with elaborate designs and increased manufacturing efficiency.

Metal 3D printing is a significant innovation in manufacturing technology that is gaining attention across industries. Complex geometries and complicated structures that are challenging or impossible to create with conventional manufacturing methods can be created thanks to this approach. This not only enhances the design capabilities but also enables the production of lightweight yet strong metal components. Metal 3D printing also offers cost and time efficiencies, as it eliminates the need for tooling, reduces material waste, and speeds up the production cycle. This technology has the potential to transform various sectors, including aerospace, automotive, healthcare, and jewellery, enabling the creation of customized and highly functional metal parts, ultimately leading to greater product innovation and competitiveness.

Key Market Segmentation:

Insights On Key component

Hardware

Hardware is expected to dominate the Global Metal 3D Printing market due to its crucial role in the manufacturing process. Metal 3D printers require high-quality hardware components such as printers, scanners, and sensors to ensure accurate and precise printing of metal objects. Industries including aerospace, automotive, and healthcare are driving the need for metal 3D printers because they need specialized hardware that can produce intricate and long-lasting metal parts. As the adoption of metal 3D printing continues to grow, the demand for advanced hardware components is expected to increase, thus driving the dominance of this subsegment in the market.

Software

While hardware takes the lead, software plays a vital role in the Global Metal 3D Printing market as well. Software solutions for metal 3D printing enable users to design and customize intricate metal objects, optimize printing processes, and perform quality control checks. These software tools offer features like modelling, slicing, and simulation, which help in achieving high precision and efficiency in metal 3D printing. It is anticipated that the need for advanced software solutions would increase due to the increasing complexity of metal designs and the requirement for bespoke solutions. Although software may not dominate the market, it represents a significant subsegment with substantial growth potential.

Services

Services encompass a wide range of activities that support the metal 3D printing market, including consulting, training, maintenance services, and post-processing. While hardware and software form the foundation, services play a critical role in ensuring the smooth operation and optimization of metal 3D printing systems. Professional services help organizations with the implementation and integration of metal 3D printing technology, ensuring that the systems are properly set up and aligned with their specific requirements. Additionally, technical support and maintenance services provide ongoing assistance to address any issues or optimize performance. While services may not dominate the market, they are essential for ensuring the successful adoption and utilization of metal 3D printing technology.

Insights On Key Technology

Selective Laser Sintering (SLS)

Selective Laser Sintering is set to dominate the Global Metal 3D Printing market due to its versatility and wide range of applications. SLS technology uses a high-powered laser to selectively fuse metal powder particles, layer by layer, to create complex metal parts with high precision. It offers excellent material properties, including high density and strength, making it ideal for producing functional metal components for various industries such as aerospace, automotive, and healthcare. SLS also enables the printing of intricate geometries and structures that may be challenging to achieve with other technologies, making it a preferred choice for many manufacturers.

Direct Metal Laser Sintering (DMLS)

Within the Metal 3D Printing market, Direct Metal Laser Sintering is another well-known subsegment. DMLS selectively melts and fuses metal powder using a powerful laser to create fully functional parts. Because of its superior mechanical qualities, accuracy, and surface quality, it can be used in applications that call for complicated designs and great precision. DMLS is widely used in industries like aerospace, medical, and automotive for manufacturing complex components, prototypes, and small-scale production runs.

Inkjet Printing

Inkjet Printing is gaining traction in the Metal 3D Printing market due to its ability to produce cost-effective, high-resolution metal parts. This technology uses a printhead to deposit metal droplets onto a build platform, which are then cured or sintered to create solid metal structures. Inkjet Printing is known for its ability to produce fine details and complex geometries, making it suitable for applications such as jewellery, dental prosthetics, and customized consumer products.

Electron Beam Melting (EBM)

Electron Beam Melting is a widely adopted Metal 3D Printing technology that utilizes an electron beam to selectively melt metal powder in a vacuum environment. EBM offers excellent material properties, including high strength and low porosity, making it suitable for critical applications in the aerospace, medical, and automotive industries. This technology allows for the production of large-scale metal components and is known for its efficiency and high build rates.

Laser Metal Deposition (LMD)

Laser Metal Deposition is a versatile Metal 3D Printing technology that uses a high-powered laser to melt and deposit metal powder onto a substrate to build complex parts layer by layer. LMD is known for its ability to perform repair and modification on existing components, as well as produce new parts with excellent material properties. It finds applications in industries such as oil and gas, aerospace, and tooling, where the ability to repair, enhance, or customize metal components is critical.

Laminated Object Manufacturing (LOM)

Laminated Object Manufacturing is a Metal 3D Printing technique that involves layering metal sheets or foils and bonding them together to create solid metal parts. LOM is known for its speed and cost-effectiveness, making it suitable for prototyping, architectural models, and tooling applications. This technology offers good material properties and surface finish but may have limitations in producing complex geometries compared to other Metal 3D Printing technologies.

Electron Beam Freeform Fabrication (EBF3)

Electron Beam Freeform Fabrication is a Metal 3D Printing technology that utilizes an electron beam to melt and deposit metal wire or powder onto a substrate to build structures layer by layer. EBF3 is particularly suitable for producing large-scale metal components with complex geometries. It finds applications in industries such as aerospace and defence, where the ability to manufacture complex, customized metal parts is essential.

Selective Laser Melting (SLM)

Using a powerful laser, selective laser melting is a metal 3D printing technique that forms solid objects layer by layer by melting and fusing metal powder. SLM offers excellent material properties and accuracy, making it suitable for manufacturing high-performance metal components. It finds applications in industries such as aerospace, healthcare, and automotive for producing complex parts, tooling, and prototypes with superior mechanical properties and surface finish.

Insights On Key software

Design Software

Design software is expected to dominate the global metal 3D printing market. This subsegment allows users to create and modify digital models for metal 3D printing, enabling customization, optimization, and prototyping of intricate metal parts. The demand for design software is driven by its ability to streamline the design process, improve accuracy, and reduce material waste. With advancements in user-friendly interfaces and simulation capabilities, design software is becoming increasingly accessible to a wider range of industries, including aerospace, automotive, and healthcare.

Inspection Software

Inspection software plays a crucial role in quality control and assurance within the metal 3D printing industry. This subsegment enables users to assess the accuracy, integrity, and structural properties of 3D-printed metal parts through various techniques such as CT scanning, X-ray inspection, and optical measurement systems. As the demand for metal 3D printed parts increases across industries, the need for reliable inspection software to ensure compliance with strict manufacturing guidelines and standards will also grow. Companies and manufacturers are investing in inspection software to uphold product quality, minimize defects, and ensure a smooth production process.

Printer Software

The printer software is an essential component of the metal 3D printing ecosystem as it controls and optimizes the printing process. This subsegment includes slicing software, which converts digital models into printable layers, and printer management software, which monitors and controls the printing parameters, material usage, and scheduling. While printer hardware advancements are crucial, printer software is equally important in achieving higher accuracy, speed, and efficiency in metal 3D printing. With the growing adoption of metal 3D printing technologies, the demand for reliable and user-friendly printer software is expected to increase.

Scanning Software

Scanning software is an integral part of reverse engineering and replication in the metal 3D printing industry. This subsegment facilitates the conversion of physical objects into digital models by capturing their geometry through techniques such as laser scanning, structured light scanning, and photogrammetry. Scanning software enables users to create accurate 3D models of existing components, parts, or moulds, which can then be directly 3D printed in metal. As industries embrace additive manufacturing for repair, replacement, and replication purposes, the demand for scanning software is anticipated to witness significant growth.

Insights On Key application

Dominating Part: Functional Parts

The functional parts subsegment is expected to dominate the Global Metal 3D Printing market. This is primarily due to the growing demand for metal 3D printed parts that can be directly integrated into functioning products across various industries. Metal 3D printing offers numerous advantages such as design flexibility, cost-effectiveness, and reduced lead time, making it an ideal choice for producing functional parts for automotive, aerospace, medical, and other end-use applications. With the advancements in metal 3D printing technology and materials, the functional parts subsegment is anticipated to witness significant growth in the coming years.

Prototyping

The prototyping subsegment is another important part of the Global Metal 3D Printing market. Metal 3D printing enables rapid prototyping with intricate designs, high accuracy, and superior material properties. It allows manufacturers to quickly iterate and refine their product designs before moving to mass production, saving time and costs associated with traditional prototyping methods. This subsegment finds applications in various industries, including automotive, consumer goods, and healthcare, among others, and is expected to witness steady growth in the global market.

Tooling

The tooling subsegment is also gaining traction in the Global Metal 3D Printing market. Metal 3D printing offers the capability to produce complex and lightweight tooling with superior durability and performance compared to conventional methods. It enables the production of customized tooling solutions for specific manufacturing processes, resulting in reduced lead time and improved efficiency. The tooling subsegment is particularly beneficial in industries such as aerospace, automotive, and manufacturing, where the demand for efficient and cost-effective tooling solutions is high.

In conclusion, while the functional parts subsegment is anticipated to dominate the Global Metal 3D Printing market, the prototyping and tooling subsegments also play significant roles. The prototyping subsegment enables rapid development and validation of product designs, while the tooling subsegment offers customized and durable tooling solutions. The advancements in metal 3D printing technology and increasing adoption across industries are driving the growth of all these subsegments, contributing to the overall expansion of the metal 3D printing market.

Insights On Key printer type

Global Metal 3D Printing Market By Printer Type:

Industrial Metal 3D Printer:

The worldwide metal 3D printing market is anticipated to be dominated by the industrial metal 3D printing subsegment. This is explained by the growing use of metal 3D printing in sectors like healthcare, automotive, and aerospace. Industrial metal 3D printers offer higher build volumes, faster printing speed, and better precision, making them suitable for large-scale production and complex metal parts. With the rising demand for customized and lightweight metal components, the industrial metal 3D printer subsegment is poised to witness significant growth in the coming years.

Desktop Metal 3D Printer:

Desktop metal 3D printers are gaining traction in various applications, including small-scale manufacturing, prototyping, and educational purposes. These printers are more affordable and compact, making them suitable for small businesses, academic institutions, and individual users. The ease of use, accessibility, and cost-effectiveness of desktop metal 3D printers are driving their demand in the market. Furthermore, the advancements in desktop metal 3D printing technology, such as improved material compatibility and print quality, are expanding their capabilities. As a result, the desktop metal 3D printer subsegment is expected to witness steady growth.

In conclusion, while the industrial metal 3D printer subsegment is projected to dominate the global metal 3D printing market due to its suitability for large-scale production and complex metal parts, the desktop metal 3D printer subsegment is also expected to experience significant growth driven by affordability, accessibility, and technological advancements.

Insights On Key vertical

Desktop Vertical

The desktop vertical segment is expected to dominate the global metal 3D printing market. This segment includes compact, affordable, and user-friendly metal 3D printers designed for small-scale and individual use. With the growing popularity of desktop 3D printers among hobbyists, educators, and small businesses, the demand for metal 3D printers in this segment is expected to witness significant growth. These printers offer the advantage of accessibility and versatility, enabling users to create complex metal parts with precision and cost-effectiveness. The desktop vertical segment is anticipated to dominate the market due to its wide-ranging applications in various industries, such as automotive, aerospace, healthcare, and consumer electronics.

Industrial Vertical

The industrial vertical segment of the global metal 3D printing market caters to the needs of large-scale manufacturing units and industrial applications. This segment includes high-performance, large-format metal 3D printers that are capable of producing complex metal components with superior precision and speed. Industrial metal 3D printers are specifically designed to meet the demands of industries such as automotive, aerospace, defence, healthcare, and oil & gas. These printers offer advanced features like multi-material printing, high-resolution printing, and scalability, making them suitable for mass production and industrial prototyping. Although the industrial vertical segment is not expected to dominate the market, it is poised for substantial growth due to the increasing adoption of metal 3D printing in industrial applications.

Other than the Dominating Part

Industrial Vertical

Industrial vertical subsegment of metal 3D printing includes high-performance metal printers utilized in various industries. These printers cater to the specific requirements of industries like automotive, aerospace, defence, healthcare, and oil & gas where precision, durability, and reliability are crucial. The industrial vertical subsegment offers advantages such as large-scale production capability, rapid prototyping, and compatibility with a wide range of materials. As industries across the globe continue to embrace the benefits of metal 3D printing for manufacturing complex parts and components, the demand for industrial metal 3D printers is expected to grow significantly.

Desktop Vertical

Desktop vertical subsegment of metal 3D printing encompasses compact and affordable metal printers designed for personal and small-scale use. These printers have gained popularity among hobbyists, educators, and small businesses due to their ease of use, accessibility, and versatility. The desktop vertical subsegment enables users to create intricate metal parts and prototypes without investing in expensive industrial-grade printers. The growing interest in DIY projects, rapid prototyping, and personalized manufacturing is expected to drive the demand for desktop metal 3D printers in various sectors, including education, jewellery, art, and small-scale production. The desktop vertical subsegment is set to witness substantial growth in the global metal 3D printing market.

Insights on Regional Analysis:

North America:

In the global metal 3D printing market, North America is expected to dominate due to the presence of major players in additive manufacturing technologies, along with extensive research and development activities in this field. The region's advanced infrastructure and strong focus on technological advancements give it a competitive advantage. Moreover, the increasing adoption of metal 3D printing in various industries, such as aerospace, healthcare, and automotive, further contributes to North America's dominance in the market. This region is likely to witness substantial growth and innovation in metal 3D printing technologies.

South America:

In South America, the metal 3D printing market is expected to experience steady growth. Although the region may not dominate the global market, it presents significant growth opportunities. Increasing investments in research and development activities, coupled with rising industrial applications, especially in sectors such as automotive, aerospace, and healthcare, are driving the demand for metal 3D printing technology in South America. The region's increasing focus on technological advancements and the adoption of additive manufacturing solutions contribute to its growth potential in the metal 3D printing market.

Asia Pacific:

Asia Pacific is poised to witness significant growth in the metal 3D printing market. With the presence of emerging economies like China, Japan, and India, the region has become a manufacturing hub. Rapid industrialization, along with increasing investments in research and development activities, is driving the adoption of metal 3D printing technology in the Asia Pacific. The automotive, aerospace, and healthcare sectors are major contributors to the demand for metal 3D printing in this region. Additionally, supportive government initiatives and partnerships with global additive manufacturing companies further fuel the growth of the metal 3D printing market in Asia Pacific.

Europe:

Europe offers a promising market for metal 3D printing, driven by the region's focus on technological advancements and manufacturing innovation. Industries such as automotive, aerospace, and healthcare are key sectors adopting metal 3D printing technology in Europe, contributing to its growing market share. The presence of leading metal 3D printing companies and research institutions in countries like Germany, the United Kingdom, and France further boosts the growth of the market in this region. Europe's emphasis on sustainability and reduced waste production aligns well with the advantages offered by metal 3D printing, hence driving its adoption.

Middle East & Africa:

Although the Middle East & Africa region may not dominate the global metal 3D printing market, it presents growth opportunities fueled by increasing industrialization and technological advancements. The automotive, aerospace, and healthcare industries in the region are gradually adopting metal 3D printing technology to improve manufacturing processes and product quality. Moreover, supportive government initiatives, collaborations with global players, and investments in research and development are expected to contribute to the growth of the metal 3D printing market in the Middle East & Africa region.

Company Profiles:

Key players in the Global Metal 3D Printing market include leaders such as General Electric and 3D Systems, who drive innovation and advanced technology adoption in this rapidly growing industry.

The metal 3D printing market is highly competitive, encompassing a range of key players. These include Arcam AB, a subsidiary of GE Additive; EOS GmbH Electro Optical Systems; Concept Laser GmbH; Renishaw plc; 3D Systems Corporation; SLM Solutions Group AG; Prodways Group; ExOne Company; Materialise NV; and Voxeljet AG, among others. These companies are renowned for their expertise in metal additive manufacturing and have established a strong presence in the market. With continuous innovation and technological advancements, these key players are driving the adoption of metal 3D printing across various industries such as aerospace, automotive, healthcare, and manufacturing. They are actively involved in research and development activities to enhance the capabilities of metal 3D printing, offer more efficient solutions, and expand their product portfolio to cater to the evolving demands of the market.

COVID-19 Impact and Market Status:

The global metal 3D printing market has been significantly impacted by the COVID-19 pandemic, with supply chain disruptions and reduced investments affecting the industry's growth.

The COVID-19 pandemic has had a significant impact on the metal 3D printing market. With restrictions on manufacturing operations and disruptions in the supply chain, many metal 3D printing companies have experienced a decline in demand and production. The aerospace and automotive industries, which are major consumers of metal 3D printed parts, have been particularly affected by the pandemic, as travel restrictions and a decrease in consumer spending have led to a decline in air travel and automobile sales. Additionally, the implementation of social distancing measures and remote working arrangements has created challenges in the adoption and implementation of metal 3D printing technologies. However, the pandemic has also highlighted the potential advantages of metal 3D printing, such as the ability to quickly produce and customize parts on demand, reducing the dependence on traditional supply chains. As a result, there has been an increased interest in metal 3D printing technologies for applications in the healthcare sector, specifically for the production of medical devices and equipment. Overall, while the COVID-19 pandemic has posed challenges for the metal 3D printing market, it has also presented opportunities for innovation and growth in certain sectors.

Latest Trends and Innovation:

- In February 2020, GE Additive announced the acquisition of an advanced metal binder jetting technology from Desktop Metal, expanding its capabilities in metal 3D printing.

- In March 2020, Stratasys Ltd. announced a partnership with Desktop Metal to integrate its bioprinting technology with Desktop Metal's metal 3D printing systems.

- In July 2020, EOS GmbH introduced a new metal 3D printing system called the EOS M 300-4, providing scalable and highly productive solutions for industrial metal additive manufacturing.

- In September 2020, HP Inc. expanded its metal 3D printing portfolio with the introduction of the HP Metal Jet Fusion technology, enabling mass production of high-quality metal parts.

- In October 2020, Renishaw plc announced the launch of the RenAM 500Q, a multi-laser metal additive manufacturing system that improves productivity in the metal 3D printing process.

- In November 2020, 3D Systems Corporation announced a strategic partnership with GF Machining Solutions, a division of Georg Fischer AG, to offer an integrated metal 3D printing solution combining 3D Systems' DMP technology and GF Machining Solutions' milling and EDM capabilities.

- In February 2021, Materialise NV acquired Link3D, a software company specializing in additive manufacturing workflow and manufacturing execution system (MES) solutions, to strengthen its position in the metal 3D printing market.

- In March 2021, ExOne Company announced the qualification of 316L stainless steel as a printable material for its metal 3D printers, expanding the range of materials available for metal 3D printing applications.

Significant Growth Factors:

The Metal 3D Printing Market is being propelled by the increasing demand for customized and complex metal parts in various industries.

The Metal 3D Printing Market is experiencing significant growth due to several key factors. First, the increasing demand for lightweight and complex metal components across industries such as aerospace, automotive, and healthcare is driving the adoption of metal 3D printing. This technology enables the production of highly intricate designs with reduced weight and improved performance. Moreover, the ability to customize and produce parts on-demand without the need for extensive tooling or moulds is attracting industries looking for cost-effective and time-efficient manufacturing solutions.

Second, advancements in metal 3D printing technologies, such as improved software, materials, and hardware, have expanded the range of applications and materials that can be printed. This has further boosted the market growth as companies can now print a wide range of metals, including titanium, aluminium, stainless steel, and nickel alloys. Additionally, the development of multi-material printing capabilities is opening new possibilities for designing and manufacturing complex assemblies with integrated functionality.

Third, the growing awareness of the environmental benefits of metal 3D printing is also contributing to market growth. Traditional manufacturing processes generate a significant amount of waste material, whereas metal 3D printing allows for more efficient use of resources and reduces material wastage. This aspect aligns with the increasing focus on sustainability and environmentally friendly practices, making metal 3D printing an attractive option for companies aiming to reduce their carbon footprint.

Lastly, the ongoing research and development activities in the field of metal 3D printing, coupled with government support and investments, are driving innovation and expanding the market. Researchers are constantly working on enhancing the speed, scalability, and cost-effectiveness of metal 3D printing, which will further propel its adoption across various industries.

In conclusion, the significant growth factors of the Metal 3D Printing Market can be attributed to the increasing demand for lightweight and complex metal components, advancements in technology, environmental benefits, and ongoing R&D efforts.

Restraining Factors:

The limited availability of raw materials and high initial investment costs are significant restraining factors for the Metal 3D Printing Market.

The Metal 3D Printing market has witnessed significant growth in recent years, but certain restraining factors hinder its full potential. Firstly, the high initial cost of metal 3D printers and raw materials is a major obstacle for many small and medium-sized enterprises, limiting their adoption of this technology.

Additionally, the limited range of materials available for metal 3D printing poses a challenge as it restricts the applicability of this technology for certain industries and applications. Moreover, the slow printing speed and limited scalability of metal 3D printers can be a hindrance in large-scale production environments, where faster and more efficient manufacturing processes are required. Furthermore, the complexity of operating and maintaining metal 3D printers and the need for skilled technicians add to the overall cost and difficulty of implementing this technology. Another restraining factor is the intellectual property and regulatory challenges associated with metal 3D printing, such as the potential for counterfeiting and the need for certifications in industries with strict quality standards. Despite these challenges, the metal 3D printing market continues to show immense potential and is expected to overcome these obstacles with advancements in technology, cost reduction, and increasing adoption. As the industry addresses these restraining factors, we can anticipate a wider range of applications, improved printing speeds, and cost-effective solutions, further driving the growth and adoption of metal 3D printing in various industries.