3D Printers Market Analysis and Insights:

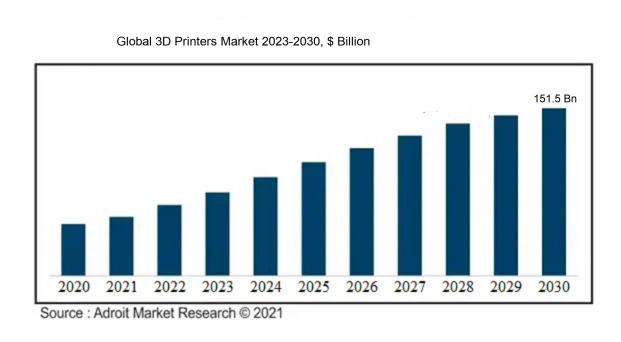

The Global 3D printer market is anticipated to grow at a compound annual growth rate (CAGR) of 21% between 2023 and 2030, according to recent industry research by Adroit Market Research Team. It is anticipated that the market would grow to a size of US$24.2 billion by 2023. The estimated value will rise to $151.5 billion by 2030.

The 3D printers market is largely influenced by several pivotal factors, including advancements in technology, falling prices of printing materials, and a growing acceptance across various industries. Innovations in printing methods, such as fused deposition modeling and selective laser sintering, not only improve the quality and speed of prints but also attract businesses aiming for greater operational efficiency. Accessibility for small and medium-sized businesses eager to include additive manufacturing into their processes is growing as the price of 3D printers and their materials continues to drop. The rising demand for personalized products, especially within sectors like healthcare, automotive, and aerospace, further stimulates market expansion as these industries aim to produce custom solutions and prototypes swiftly. Environmental considerations also play a role in this trend, as 3D printing typically results in less waste compared to conventional manufacturing techniques. As a result, the interplay of technological advancements, cost efficiency, adaptability across industries, and sustainability factors significantly drives the growth of the 3D printer market.

3D Printers Market Definition

Three-dimensional printers are cutting-edge devices that fabricate objects by building them layer by layer according to digital prototypes. These machines employ different techniques, including Fused Deposition Modeling (FDM) and Stereolithography (SLA), to achieve intricate and accurate designs.

Three-dimensional printing is integral to contemporary manufacturing and innovation, facilitating swift prototyping and tailored product designs. This technology empowers designers and engineers to construct intricate forms that conventional techniques cannot replicate, thereby shortening development times and lowering expenses. Additionally, it supports sustainability efforts by reducing material waste and producing lighter, more efficient parts. 3D printing also encourages creativity, allowing individuals and companies to refine their designs rapidly, which drives experimentation and innovation across multiple sectors such as healthcare, automotive, and aerospace. As a flexible resource, 3D printing is transforming the landscape of production and product advancement.

3D Printers Market Segmentation:

Insights On Key Component

3D Printers

3D printers are anticipated to rule the global 3D printer market because of the growing need for tooling and prototyping across a range of industries, including consumer products, automotive, aerospace, and healthcare. The continuous advancements in technology, such as faster print speeds, better material compatibility, and improved printing precision, are attracting more businesses to invest in 3D printing. Additionally, the reduction in costs associated with 3D printing equipment has made it more accessible to small- and medium-sized enterprises. Thus, the proliferation of applications and the push towards customization across sectors heavily contribute to the prevailing strength of 3D Printers in the market.

3D Printing Services

3D Printing Services encompass a range of outsourced manufacturing activities involving the creation of 3D printed products on behalf of clients. This plays a crucial supporting role in the industry, particularly for businesses that lack in-house capabilities or wish to test the waters of 3D printing without large initial investments. Companies often leverage these services to produce prototypes and limited runs of products quickly and efficiently. The growing trend toward rapid prototyping and the need for on-demand production are significant factors contributing to the demand for 3D Printing Services.

3D Printing Software

3D Printing Software is essential for facilitating the design, preparation, and management of 3D printing processes. This component includes software for modeling, slicing, and managing 3D printing devices. Enhanced software solutions enable users to optimize printing parameters and improve overall print quality, thus becoming integral in advancing the efficiency of the 3D printing workflow. With the rise of complex designs and the necessity for improved collaboration tools, the need for sophisticated 3D Printing Software continues to grow in tandem with the overall expansion of the market.

Consulting Services

Consulting Services in the 3D printing sector provide valuable expertise to organizations seeking to implement 3D printing technologies. They help businesses to analyze their needs, identify suitable technologies, and devise integration strategies for 3D printing within their operations. As the industry matures, more companies are realizing that strategic insights and tailored solutions can lead to more efficient use of 3D printing. Therefore, the role of consulting can significantly influence the successful adoption and implementation of 3D printing technologies, resulting in a growing demand for expert consulting services.

Support Services

Support Services related to 3D printing include maintenance, troubleshooting, and technical assistance for 3D printers, software, and related technologies. As more businesses adopt 3D printing, the need for reliable support becomes increasingly important to ensure uninterrupted production and optimal performance of printing systems. Effective support services can enhance customer satisfaction and foster long-term relationships, leading to increased repeat business and brand loyalty. Consequently, this sector plays an essential role in bolstering the growth and stability of the overall 3D printing market.

Others

The "Others" category refers to various niche components or emerging technologies related to 3D printing that don't fall into conventional classifications. This can include specialized materials, government regulations, standards, or educational initiatives aimed at fostering understanding of 3D printing technologies. While this currently contributes less to the market than the major components, it holds potential for future growth as companies explore innovative applications and as educational resources become increasingly essential in integrating 3D printing into more industries.

Insights On Key Technology

Fused Deposition Modelling (FDM)

Fused Deposition Modelling (FDM) is expected to dominate the Global 3D Printers Market due to its versatility, affordability, and ease of use, making it highly accessible to both hobbyists and industrial applications. The technology uses thermoplastic filaments to create objects layer by layer, which allows for rapid prototyping and a diverse range of material options. FDM systems are increasingly being adopted in various industries, including education, aerospace, automotive, and healthcare. Moreover, advancements in materials and increased production capabilities have contributed to FDM’s growing market share, positioning it as the leading technology in the 3D printing landscape.

Digital Light Processing (DLP)

Digital Light Processing (DLP) is gaining traction in the 3D printing market, particularly for applications requiring high-resolution and speed. Utilizing a digital light projector to cure resin layer by layer, DLP prints are characterized by their fine detail and smooth surfaces. This technology is popular in dentistry and jewelry making where precision is paramount. Furthermore, DLP systems can print multiple objects simultaneously, increasing efficiency. Continuous improvements in DLP technology and the development of new resins further enhance its appeal, creating a promising outlook for its continued growth in the 3D printing industry.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is becoming increasingly important in industrial settings, particularly for producing complex and highly durable metal components. This technology employs a laser to sinter powdered metal into solid parts, making it ideal for aerospace, automotive, and medical applications where strength and reliability are crucial. DMLS allows for intricate geometries that traditional manufacturing processes cannot achieve, thereby enhancing design freedom. The ongoing advancements in metal powders and laser technology are expected to further bolster DMLS growth, ensuring its relevance in the competitive landscape of 3D printing.

Electron Beam Melting (EBM)

Electron Beam Melting (EBM) represents a significant technology for high-performance metal parts, especially in aerospace and medical applications. It employs an electron beam to melt metallic powders in a vacuum environment, resulting in dense and complex structures. EBM is particularly advantageous for producing large, intricate components and offers excellent mechanical properties. While traditionally more expensive, the capacity for producing custom parts on-demand is driving interest in EBM. The advancement of vacuum technologies and electron beam systems are expected to enhance the capabilities and affordability of EBM, ensuring its continual role in the 3D printing sector.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) has established its presence in commercial 3D printing, especially for creating highly functional prototypes and end-use parts. This technology utilizes a laser to selectively fuse powdered material, typically thermoplastics, to form intricate geometrical shapes with excellent mechanical properties. SLS is particularly noted for its ability to produce parts with complex internal structures without the need for support materials, making it suitable for a variety of industries including automotive, aerospace, and consumer products. The continued advancement in SLS materials and processes highlights its strong potential for future growth in the 3D printing market.

Stereolithography

Stereolithography is one of the earliest 3D printing technologies and remains relevant due to its capability for producing high-accuracy prototypes with smooth surfaces. This technique uses UV light to cure liquid resin layer by layer, allowing for rapid production of complex geometries. It is particularly popular in sectors such as healthcare, where detailed models are essential. Stereolithography machines have seen improvements in speed and cost-effectiveness, making them more appealing for both prototyping and short-run production. The innovations in resin formulations are also expanding the applications of stereolithography, which enhances its position in the evolving market landscape.

Others

The "Others" category encompasses various niche technologies that cater to specific needs within the 3D printing market. These may include methods like Laminated Object Manufacturing (LOM), material jetting, and binder jetting, each offering unique advantages. While these technologies do not dominate the market, they serve specialized applications, such as creating paper models or multi-material prototypes. The growth of these alternatives is fueled by specific industry demands and ongoing research into new materials and techniques. Their adaptability allows them to find a place alongside more mainstream technologies, contributing to the diversity of the 3D printing ecosystem.

Insights On Key Application

Production Parts

Production parts are expected to dominate the Global 3D Printers Market due to the increasing demand for customized and complex components across various industries, including aerospace, automotive, and healthcare. As companies seek to enhance efficiency, reduce material wastage, and accelerate time-to-market, 3D printing technology allows for the fabrication of highly specialized production parts that can be produced on-demand. Furthermore, advancements in materials and printing techniques have improved the strength and durability of 3D printed parts, making them suitable for end-use applications. As industries move towards digital manufacturing and Industry 4.0, the reliance on production parts will escalate, reinforcing its leading position in the market.

Prototypes

Prototyping is a vital application in the 3D printing industry, particularly for product development processes in sectors like consumer goods, electronics, and automotive. The rapid iteration of designs allows engineers and designers to create and test multiple prototypes quickly, fostering innovation and minimizing development costs. However, while prototyping has established its significance by enabling faster feedback loops and reducing time-to-market for new products, it is increasingly being supplemented by production parts as companies look to move prototypes into full-scale production using the same technology.

Tools & Fixtures

The Tools & Fixtures application within the 3D printing market addresses the need for custom tooling solutions in manufacturing processes. This application provides precision and efficiency, allowing manufacturers to create jigs, fixtures, and molds tailored to specific tasks. By utilizing 3D printing for these supporting tools, companies can reduce lead times and costs associated with traditional tooling methods. Despite its importance, the overall demand for tools and fixtures is not expected to outpace the growth forecasted for production parts and prototyping, as businesses prioritize end-use applications.

Insights On Key Industry

Healthcare & Medical Devices

Healthcare & Medical Devices is expected to dominate the Global 3D Printers Market due to the increasing adoption of additive manufacturing technologies in the medical field. This industry benefits significantly from 3D printing applications, such as creating patient-specific prosthetics, dental implants, surgical instruments, and bioprinting tissues and organs. The growing need for personalized medicines and rapid prototyping in the healthcare sector drives innovation and development, making this area a hotbed for advancements in 3D printing technology. Additionally, the increasing investments in healthcare infrastructure, coupled with the push for affordable and efficient manufacturing processes, solidifies the standing of the Healthcare & Medical Devices category within the 3D printing landscape.

Aerospace & Aeronautics

The Aerospace & Aeronautics industry is seeing considerable growth in the use of 3D printing technologies, primarily aimed at reducing weight and improving fuel efficiency in aircraft. Manufacturers are leveraging additive manufacturing to create complex components that were previously impossible or cost-prohibitive to produce using traditional methods. The capability to customize parts while reducing lead times and waste is particularly valuable for aerospace companies striving for higher performance and sustainability. The collaboration between aircraft manufacturers and 3D printing firms also enhances innovation, ensuring the industry's promising growth and adaptation.

Automotive

The Automotive sector is increasingly integrating 3D printing solutions for prototyping, production tooling, and even direct part manufacturing. Automakers are seeking ways to enhance production efficiency and reduce costs, which has led to the adoption of additive manufacturing techniques for creating lightweight components and rapid concept validations. The ability to produce aftermarket parts and customizations at a lower cost has also positioned 3D printing as a favorable alternative for automotive designs. As this industry prioritizes efficiency and sustainability, the adoption of 3D printing will likely continue to expand significantly.

Consumer Goods

In the Consumer Goods industry, 3D printing offers customization and personalization that appeal to modern consumers. This sector utilizes 3D printing for rapid prototyping, allowing brands to develop innovative products that meet specific customer demands. Additionally, 3D printing can help reduce inventory and waste by enabling on-demand production. The rise of customizable fashion items, home accessories, and personalized gifts is gaining traction and showcases how consumer preferences align with the capabilities of additive manufacturing. As companies adapt to consumer trends, the use of 3D printing technologies is expected to increase in this sector.

Industrial

The Industrial industry is leveraging 3D printing for tooling, jigs, and fixtures, as well as for creating complex components for machinery. This method allows for shorter lead times and increased manufacturing efficiency, essential factors in the highly competitive industrial market. Companies can also achieve greater design freedom and reduce material waste with additive manufacturing approaches. As industries strive for cost-effectiveness and innovative solutions, the application of 3D printing technologies in this area continues to grow. The continuous evolution of industrial applications for 3D printing ensures its relevance and adoption in various manufacturing processes.

Others

The "Others" category encompasses various niche applications of 3D printing across different fields, such as education, architecture, and art. While these applications are burgeoning, they lack the scale and volume seen in larger industries like healthcare or automotive. Nonetheless, educational institutions are using 3D printing to enhance learning experiences by allowing students to engage in hands-on projects. Similarly, in architecture, 3D printing provides opportunities for rapid modeling and prototyping. While its impact is noticeable, it remains overshadowed by the primary sectors, which drive significant revenue and innovation in the global 3D printing market.

Insights on Regional Analysis for 3D Printers Market:

Asia Pacific

The Asia Pacific region is expected to dominate the Global 3D Printers market due to several compelling factors. This region boasts a robust manufacturing ecosystem, characterized by rapid industrialization and a strong emphasis on technological advancements, particularly in countries like China, Japan, and South Korea. The rise of startups focusing on innovative 3D printing applications across various sectors such as healthcare, aerospace, and automotive has fueled growth. Additionally, the increasing investment in additive manufacturing technologies and supportive government policies have created a thriving environment for 3D printers. Collectively, these elements position Asia Pacific as the frontrunner in the global 3D printing landscape.

North America

North America remains a significant player in the Global 3D Printers market, primarily driven by strong demand from industries such as aerospace, automotive, and healthcare. The region is home to several leading manufacturers and innovators in 3D printing technologies, which fosters a competitive landscape for advancements. Additionally, the high adoption rate of 3D printing for prototyping and production processes among various businesses, alongside robust research and development initiatives, contributes to its steady growth. The presence of key stakeholders and significant investment in advanced technologies further enhances the region's position in the market.

Europe

Europe is witnessing an uptick in 3D printer adoption, fueled by increasing investments in research and development alongside a rising emphasis on sustainability and customized manufacturing solutions. Countries like Germany and the UK are leading the charge with their advanced manufacturing capabilities and strong regulatory frameworks. The growing integration of 3D printing into traditional manufacturing processes, particularly in industries like automotive and healthcare, signifies a transformative shift. Moreover, collaborative efforts among businesses and academic institutions foster innovation, making Europe a noteworthy contender in the global market.

Latin America

In Latin America, the 3D printing market is gradually gaining traction fueled by increasing awareness and acceptance of additive manufacturing technologies. Countries like Brazil and Mexico show potential for growth, especially in sectors like education, healthcare, and construction. However, the region faces challenges such as limited technological infrastructure and investment hurdles. Despite these obstacles, several initiatives aimed at promoting industrial growth and digitization signal a positive outlook for the future of the 3D printing market in Latin America as local enterprises explore new applications and opportunities.

Middle East & Africa

The 3D printers market in the Middle East & Africa is still in its nascent stage but has begun to garner interest, particularly in sectors like construction and healthcare. Economic diversification efforts in countries like the UAE and South Africa are driving investments in advanced technologies, including 3D printing. However, infrastructure and market maturity challenges persist, hindering faster growth. As awareness grows and investments in education and training increase, the region may witness a gradual shift towards greater adoption of 3D printing technologies moving forward.

3D Printers Market Company Profiles:

Prominent participants in the worldwide 3D printing industry, including producers and tech developers, spearhead advancements, improve manufacturing efficiencies, and broaden the range of applications across multiple sectors. Their collaborations and financial commitments to research and development are essential for creating cutting-edge printing technologies and addressing the increasing demands of the market.

The 3D printing industry is primarily dominated by several key players, including Stratasys Ltd., 3D Systems Corporation, HP Inc., Siemens AG, Materialise NV, Ultimaker B.V., EOS GmbH, Desktop Metal, Inc., Carbon, Inc., Renishaw PLC, SLM Solutions Group AG, and Formlabs, Inc. In addition, notable companies such as MakerBot Industries, LLC, HP Inc., Xaar PLC, and Prusa Research s.r.o. also hold significant positions within the market. Other important contributors include Raise3D, Markforged, and NEMEON, all of which are acknowledged for their crucial roles in enhancing and innovating 3D printing technologies across a wide range of both industrial and consumer sectors.

COVID-19 Impact and Market Status for 3D Printers Market:

The Covid-19 pandemic significantly expedited the integration of 3D printing technologies in numerous sectors, underscoring their capability for swift prototyping and enhancing the robustness of supply chains.

The COVID-19 pandemic had a profound effect on the 3D printers market, presenting both hurdles and new possibilities. At the outset, supply chain disruptions and pauses in production led to reduced manufacturing capabilities and limited availability of components. Numerous companies encountered operational difficulties stemming from health regulations and a shortage of workforce. Nevertheless, this crisis propelled innovation forward, as various industries sought swift solutions to adapt to evolving demands, especially in the healthcare sector. Hospitals began utilizing 3D printing technologies to produce essential medical items, including personal protective equipment (PPE) and components for ventilators, showcasing the versatility of the technology. The pandemic emphasized the value of localized, just-in-time production, resulting in ened investments in 3D printing across multiple fields such as automotive, aerospace, and consumer goods. As economies began to rebound, the 3D printing sector also started to recover, with an increasing focus on resilience and sustainability that suggests a potential long-term transformation in manufacturing strategies in the post-pandemic landscape.

3D Printers Market Latest Trends and Innovation:

- In May 2021, Stratasys announced the acquisition of Printlet, a startup that specializes in software for additive manufacturing, aimed at enhancing Stratasys’s capabilities in improving 3D printing workflows.

- In September 2022, HP Inc. launched its new jet fusion 5200 series 3D printers, which offer enhanced speed and quality for production, alongside advancements in materials development to support a broader range of applications.

- In December 2021, Materialise entered into a collaborative partnership with Siemens to integrate their software solutions, which posits an augmented capacity for 3D printing in the manufacturing sector, particularly for medical and aerospace applications.

- In March 2023, 3D Systems acquired software firm Oqton, which provides AI-driven automation and data analytics for additive manufacturing processes, strengthening their position in digital manufacturing.

- In June 2023, EOS introduced its new EOS P 500, which represents a significant upgrade in speed and material diversity for industrial polymer 3D printing, targeting the automotive and aerospace industries.

- In January 2022, Desktop Metal announced its acquisition of Envelop 3D, a company known for its innovative large-format 3D printing technology, expanding Desktop Metal’s portfolio in the market for advanced manufacturing solutions.

- In August 2023, Relativity Space raised $500 million in funding to enhance the capabilities of its 3D printing technology for aerospace applications, reflecting growing investments in space technology and additive manufacturing.

- In October 2022, Xact Metal revealed its XM200C metal printer, which utilizes lower-cost materials while delivering high-resolution prints, targeting the need for affordability in metal 3D printing.

- In April 2023, SANDVIK acquired the advanced manufacturing company, 3D-Micromac, to enhance its own capabilities in the metal additive manufacturing sector, indicating the growing trend towards consolidation in the industry.

3D Printers Market Significant Growth Factors:

Crucial elements driving the expansion of the 3D printing market comprise technological innovations, a rising need for quick prototyping solutions, and a broadening range of applications within diverse sectors, including healthcare and aerospace.

The market for 3D printing technology is experiencing notable expansion, fueled by several important dynamics. Primarily, technological advancements have resulted in the creation of 3D printers that are faster, more dependable, and economically viable, allowing a broader spectrum of industries to utilize them. A marked increase in the demand for customized products is particularly evident in areas such as aerospace, automotive, and healthcare, where bespoke solutions significantly improve operational efficacy and performance. Furthermore, ened investments in research and development are driving innovation, paving the way for new materials and applications that extend the potential of 3D printing. The shift towards sustainable manufacturing practices is also playing a crucial role in market expansion, as 3D printing holds the potential to minimize material waste and reduce energy usage. The COVID-19 pandemic underscored the benefits of additive manufacturing in swiftly supplying critical products, further accelerating its uptake. Additionally, the growth of e-commerce and the need for just-in-time production resonate well with the strengths of 3D printing, allowing businesses to swiftly respond to consumer demands. Together, these elements are advancing the market, creating abundant opportunities for stakeholders within the 3D printing landscape.

3D Printers Market Restraining Factors:

Major barriers in the 3D printing industry encompass elevated equipment expenses, restricted selection of materials, and regulatory hurdles.

The 3D printing industry encounters multiple challenges that could impede its expansion. The substantial upfront investment required for advanced 3D printing equipment, especially for industrial applications, acts as a considerable obstacle for small to mid-sized businesses looking to embrace this technology. Moreover, the narrow spectrum of materials compatible with certain printers limits their use across various fields. Technical hurdles, such as the necessity for specialized knowledge to operate and service high-tech printers, may discourage potential users from entering the market. Additionally, concerns related to intellectual property rights regarding the duplication of patented designs can introduce legal complexities, creating hesitation among prospective users. The market's fragmentation, characterized by a plethora of manufacturers and swiftly advancing technologies, can confuse consumers, making it challenging for them to select appropriate options. Furthermore, the slower production rates in comparison to traditional manufacturing processes may restrict the scalability of 3D printing in sectors like automotive and aerospace. Nevertheless, continuous improvements in materials, technology, and decreased costs are fostering increased adoption. As the industry addresses these challenges and progresses, the outlook for 3D printing remains bright, promising transformative solutions across diverse industries.

3D Printers Market Key Segmentation:

By Component

- 3D Printers

- 3D Printing Services

- 3D Printing Software

- Consulting Services

- Support Services

- Others

By Technology

- Digital Light Processing (DLP)

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

- Fused Deposition Modelling (FDM)

- Selective Laser Sintering (SLS)

- Stereolithography

- Others

By Application

- Production Parts

- Prototypes

- Tools & Fixtures

By Industry

- Aerospace & Aeronautics

- Automotive

- Consumer Goods

- Healthcare & Medical Devices

- Industrial

- Others

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America