Specialty Alumina Market Analysis and Insights:

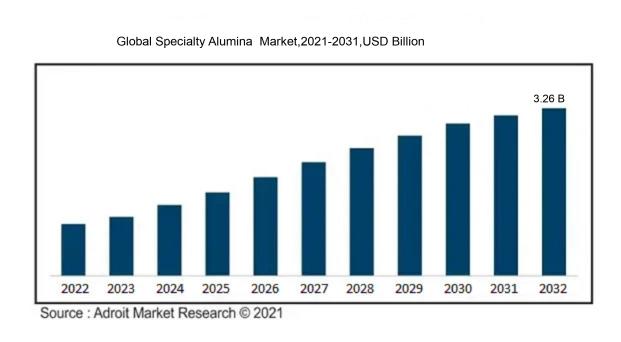

In 2023, the size of the worldwide Specialty Alumina market was US$ 2.56 billion. Adroit Market Research projects that the market will increase at a compound annual growth rate (CAGR) of 2.71% from 2024 to 2032, reaching US$ 3.26 billion.

The market for specialty alumina is propelled by several pivotal factors, particularly the surge in demand for high-performance materials across various sectors such as ceramics, electronics, and pharmaceuticals. The automotive industry, especially with the recent growth of electric vehicles, is intensifying the need for cutting-edge materials that possess superior thermal and electrical attributes. Moreover, the increasing utilization of specialty alumina as a catalyst in diverse chemical applications, along with its significance in manufacturing refractory materials, fuels market advancement. Stricter environmental regulations that advocate for the adoption of energy-efficient and sustainable materials further encourage innovation within specialty alumina applications. Additionally, the rapid urbanization and infrastructure development seen in developing regions are elevating the demand for construction materials that leverage specialty alumina for enhanced functionality and longevity. Collectively, these elements, alongside ongoing R&D initiatives aimed at broadening the scope of applications, play a crucial role in influencing the future direction of the specialty alumina market.

Specialty Alumina Market Definition

Specialty alumina denotes high-purity alumina products designed for targeted uses, distinguished by distinctive features such as exceptional thermal stability and superior chemical resilience. These materials find widespread application in industries including ceramics, electronics, and catalysis.

Specialty alumina is vital across numerous sectors owing to its distinctive characteristics, such as remarkable thermal stability, superior chemical resistance, and increased mechanical strength. It finds extensive applications in areas like ceramics, catalysis, and electronics, where it functions as a fundamental component in high-performance materials. Furthermore, specialty alumina is integral to the manufacturing of abrasives, refractories, and sophisticated coatings, enhancing both durability and operational efficiency. As the need for sustainable and innovative solutions rises, the adaptability and performance attributes of specialty alumina are becoming increasingly significant in the advancement of cutting-edge technologies and eco-friendly products across various industries.

Specialty Alumina Market Segmental Analysis:

Insights On Type

Activated Aluminas

Activated aluminas are expected to dominate the Global Specialty Alumina Market due to their versatile applications in adsorbents, catalysts, and desiccants. Their ability to provide high surface area and efficient absorption capacities makes them increasingly relevant in industries such as petrochemicals, pharmaceuticals, and water treatment. Additionally, the growing demand for innovative materials in battery technologies and oil refining processes enhances their market position. With continual advancements in activated alumina manufacturing processes and a strong focus on sustainability, this category is set to lead the industry in the coming years.

Aluminium

Aluminium, as a type of specialty alumina, plays a crucial role in various applications including aerospace, automotive, and constructions due to its lightweight and corrosion-resistant properties. The global emphasis on fuel efficiency in the automotive sector is driving growth in the use of aluminium in vehicle manufacturing. Moreover, innovations in aluminium alloys and composites are opening new avenues for this material in high-performance applications. However, despite its significance, aluminium is expected to be overshadowed by activated aluminas, which offer specialized functionalities and efficiencies in various industrial processes.

Trihydroxide (ATH)

Trihydroxide, or Aluminum Trihydroxide (ATH), finds widespread use as a flame retardant due to its ability to release water vapor when heated, which helps in reducing fire hazards. Its applications extend to plastics, rubber, and coatings where fire resistance is paramount. Additionally, ATH serves as an effective filler in various materials, enhancing their properties. While it maintains a strong position in specific markets, such as building materials and automotive applications, it is not expected to surpass the dominance of activated aluminas which align more closely with higher-value applications.

Boehmite

Boehmite is valued for its unique properties, particularly in fields such as ceramics and catalysis. Its fine particle size allows nanostructured materials to be produced, making it particularly sought after in the production of advanced ceramics and coatings. Furthermore, Boehmite plays a notable role in catalysts and battery components, where its high purity and thermal stability are advantageous. Despite its niche applications, Boehmite is not forecasted to outpace activated aluminas, which cater to broader industrial demands and offer enhanced performance in various applications.

Calcined Alumina

Calcined alumina, produced from the calcination of alumina hydrate, is essential in the manufacturing of abrasives, refractories, and as a raw material in aluminum production. Its high hardness and stability at elevated temperatures make it particularly suitable for refractory applications where reliability is critical. Moreover, Calcined alumina is also utilized in the ceramic industry for its excellent binding capabilities. Although it holds a vital spot in the market, it struggles to compete against activated aluminas, which are increasingly favored for their multifunctional properties and specialized uses.

Tabular Alumina

Tabular alumina is known for its exceptional hardness and thermal shock resistance, primarily used in refractory applications. It is produced by the sintering of calcined alumina, resulting in a high-purity material that offers excellent corrosion resistance. Manufacturers prefer tabular alumina for high-performance applications, including furnaces and casting processes, due to its durability. Nevertheless, while tabular alumina remains crucial for specific structural applications, it is anticipated that activated aluminas will continue to dominate the market thanks to their versatility and comprehensive utilization across various industries.

Fused Alumina

Fused alumina is widely recognized for its use in abrasives and grinding applications, providing a tough and durable material ideal for cutting and polishing. Due to its high melting point and mechanical strength, fused alumina serves a role in both metal and non-metal industries. Its applications span from automotive to construction sectors, primarily in sandblasting and surface preparation. Even though fused alumina retains a steady market presence, it pales in comparison to activated aluminas, whose expanded attributes and specialized functions make them more appealing in contemporary applications.

Insights On Application

Chemical Industry

The Chemical Industry is expected to dominate the Global Specialty Alumina Market due to its extensive applications across various sectors such as catalysts, adsorbents, and refractory materials. The rising demand for specialty chemicals and advanced materials for both industrial and consumer applications drives the need for high-purity alumina. Furthermore, innovations in the production processes and the increasing adoption of alumina in advanced applications offer significant growth opportunities. Concomitantly, environmental regulations favor the utilization of specialized materials that promote efficiency and sustainability, positioning the Chemical Industry as a player in this market.

Mining

The Mining sector is primarily focused on the extraction of aluminum ore, which remains crucial for the production of alumina. While this application does not demand specialized forms at the same level as chemicals, it significantly contributes to the overall alumina market. The increasing global demand for metals, especially in emerging economies, continues to drive investment in mining activities, thus sustaining a steady market for various grades of alumina extracted.

Architecture

In Architecture, specialty alumina finds applications in the production of high-performance materials such as glass, ceramics, and insulation products. The rising trend of sustainable and eco-friendly building materials enhances the demand for alumina-based products, promoting energy efficiency and durability in construction. Architects and developers increasingly recognize the aesthetic and functional benefits of incorporating specialty alumina, which is likely to continue driving its use in innovative building solutions.

Automobile

The Automobile sector leverages specialty alumina mostly in lightweight materials that improve fuel efficiency and performance. As the automotive industry emphasizes the reduction of emissions, there is a growing trend towards the incorporation of advanced materials that can withstand high temperatures while maintaining structural integrity. Specialty alumina serves as a crucial ingredient in components such as brake pads and other engine parts, resulting in a steady demand as manufacturers pursue sustainability.

Aerospace & Defense

The Aerospace & Defense industries prioritize specialty alumina for its thermal stability, lightweight characteristics, and resistance to corrosion. These properties make alumina indispensable in the production of advanced ceramic composites and insulating materials crucial for high-performance applications, such as aircraft components and defense gear. As global defense expenditures rise and aerospace technologies advance, the demand for specialty alumina in these sectors is expected to grow accordingly.

Electric Appliances

In Electric Appliances, specialty alumina is used in the development of insulating materials and thermal management systems, contributing to enhanced energy efficiency and safety. With the increasing focus on smart home technologies and energy-efficient appliances, the demand for high-quality alumina in electrical components continues to rise. Manufacturers are integrating advanced materials to achieve better performance and longevity, which further propels the market for specialty alumina in this application area.

Other

The 'Other' category includes various niche applications of specialty alumina, such as in catalysts for petrochemical processes, water treatment, and electronics. While this represents a smaller market share compared to the dominating sectors, innovations in technology and manufacturing processes consistently create new applications. The ongoing quest for sustainability and efficiency across industries could provide emerging opportunities for specialty alumina in unconventional applications, which may contribute to its gradual growth in the overall market.

Global Specialty Alumina Market Regional Insights:

Asia Pacific

The Asia Pacific region is expected to dominate the Global Specialty Alumina market due to rapid industrial growth in countries such as China and India. These countries are experiencing significant demand for specialty alumina in various applications, including electronics, automotive, and construction. The increasing adoption of advanced materials and cutting-edge technologies in manufacturing further propels the market's growth in this region. Additionally, the presence of large-scale production facilities and favorable government policies that support industrialization and innovation contribute to the Asia Pacific's competitive advantage, making it the primary driver in the specialty alumina landscape.

North America

North America is witnessing a steady growth in the Specialty Alumina market, primarily driven by advancements in technology and industrial applications. The region boasts a strong manufacturing base, especially in the automotive and aerospace sectors, which utilize specialty alumina for its unique properties. Furthermore, increased investments in research and development, coupled with a focus on high-performance materials, bolster the demand. The expansion of ceramic materials within various industries also plays a vital role in North America's contribution to the global specialty alumina market.

Europe

Europe presents a substantial market for Specialty Alumina, largely due to stringent regulations on product quality and performance in various sectors. European manufacturers are focusing on environmentally friendly production processes, which has led to innovations in specialty alumina applications, especially in catalysts and electronics. The region's robust automotive sector and growing demand for lightweight materials further enhance the adoption of specialty alumina. Collaborative efforts among industry players and research institutions are also fueling advancements, positioning Europe as a significant participant in the specialty alumina market despite competition from other regions.

Latin America

Latin America is gradually emerging in the Global Specialty Alumina market, driven by the growth of sectors such as mining, construction, and electronics. Countries like Brazil and Argentina are focusing on infrastructural development, which indirectly boosts the demand for specialty materials. However, the region faces challenges, including economic volatility and less industrial capacity compared to North America and Asia Pacific. Yet, with growing investments and international partnerships aimed at enhancing manufacturing capabilities, Latin America has potential for notable growth in the specialty alumina sector over the coming years.

Middle East & Africa

The Middle East and Africa region is at an early stage in its development of the Specialty Alumina market. While there is potential for growth driven by the expansion of the petrochemical and construction industries, the region faces challenges such as limited infrastructure and underdeveloped supply chains. However, with ongoing investments in infrastructure projects and a push towards diversifying economies, there are opportunities for specialty alumina to gain traction. As regional economies continue to expand, the demand for high-performance materials may eventually rise, contributing to market development in the future.

Specialty Alumina Market Competitive Landscape:

Prominent figures within the Global Specialty Alumina sector propel innovation and expansion by creating specialized materials designed for particular uses, while also maintaining effective supply chain operations and market competitiveness. Their collaborative alliances and financial investments support the investigation of novel technologies and entry into developing markets.

The Specialty Alumina market features several players, including Alcoa Corporation, Almatis GmbH, Nordic Mining ASA, Heemskerk Aluminum, and Sumitomo Chemical Co., Ltd., along with Friedrich K PIPE and Investment Holdings Ltd., NALCO (National Aluminium Company Limited), and Axis Solar Energy Pvt. Ltd. Other significant contributors encompass Showa Denko K.K., Imerys S.A., Huber Engineered Materials, Rusal, Sanmin Aluminates Co., Ltd., China Aluminum International Engineering Corp, and Shandong Aluminium Industry Co., Ltd. These firms play essential roles in the manufacturing and distribution of specialty alumina products, which find applications across a variety of industries.

Global Specialty Alumina Market COVID-19 Impact and Market Status:

The Covid-19 pandemic significantly impacted the Global Specialty Alumina market by creating disruptions in supply chains and leading to a reduction in industrial demand, especially within the automotive and construction industries.

The COVID-19 pandemic profoundly affected the specialty alumina sector, mainly due to interruptions in supply chains and a dip in industrial output. With numerous manufacturing facilities either closing or scaling back operations to adhere to health guidelines, the demand for specialty alumina in industries such as ceramics, automotive, and electronics declined significantly. Furthermore, global trade limitations and logistical hurdles resulted in delays in the procurement of both raw materials and finished goods. Nevertheless, as economies began to recover and sectors adjusted to new operational frameworks, there was a notable rebound in the demand for specialty alumina, especially in uses like catalysts and advanced ceramics. The market has been steadily rebounding, fueled by rising investments in infrastructure and a shift toward sustainable technologies. In summary, while the pandemic initially impeded growth, it also underscored the specialty alumina industry's resilience and ability to adapt to obstacles.

Latest Trends and Innovation in The Global Specialty Alumina Market:

- In February 2023, Almatis, a global leader in specialty alumina, announced the expansion of its production capacity at its facility in Bellenberg, Germany, in response to the growing demand from the ceramics and coatings sectors.

- In May 2023, Alcoa Corporation completed the acquisition of the specialty alumina business of its competitor, the aluminum giant Norsk Hydro, enhancing its product portfolio in high-performance materials used across multiple industries.

- In July 2023, the Saudi Arabian company Ma'aden (Saudi Arabian Mining Company) launched a new line of specialty alumina aimed at supporting the advanced ceramics market, intending to cater to local and international demand.

- In August 2023, the German company Kurses GmbH unveiled a breakthrough in the production of alumina through a new environmentally friendly process that significantly reduces carbon emissions, positioning itself as a leader in sustainable manufacturing.

- In September 2023, Ube Industries Ltd. announced a joint venture with a major Chinese enterprise to leverage innovations in specialty alumina applications for the automotive industry, focusing on enhanced performance and lightweight materials.

- In October 2023, BASF SE introduced a new line of specialty alumina products designed for catalysts in the chemical industry, featuring enhanced thermal stability and improved performance in a variety of conditions.

Specialty Alumina Market Growth Factors:

The expansion of the Specialty Alumina market is fueled by a rising need in industries like automotive, electronics, and pharmaceuticals, coupled with innovations in manufacturing processes.

The Specialty Alumina market is experiencing significant expansion due to several pivotal influences. Primarily, the ened demand from diverse end-use sectors—including ceramics, electronics, and automotive—serves as a catalyst for this growth. The distinctive attributes of specialty alumina, such as impressive thermal stability and superior dielectric strength, render it indispensable in the manufacturing of cutting-edge ceramics and electronic devices. Additionally, the increasing focus on sustainable and efficient production methods in areas like battery technology and catalytic processes is fostering greater adoption of specialty alumina.

Moreover, the automotive industry’s pursuit of lightweight materials, driven by stringent emission standards, is further propelling market growth. Technological advancements and improved manufacturing techniques are also enhancing the performance of specialty alumina, making it a favored option across a variety of applications. The intensifying emphasis on research and development in critical fields such as pharmaceuticals and biomaterials is contributing to this market's growth trajectory. Finally, the globalization of supply chains and escalating investments in developing regions are opening up new avenues for market participants, promoting further advancement in the specialty alumina sector as industries move toward more innovative and effective solutions.

Specialty Alumina Market Restaining Factors:

The Specialty Alumina market faces several challenges, including variable costs of raw materials and strict environmental regulations that affect manufacturing practices.

The Specialty Alumina Market is currently encountering several obstacles that could impede its expansion. A primary concern is the volatility in raw material prices, which can elevate production expenses and diminish profit margins for producers. Additionally, rigorous environmental regulations related to alumina manufacturing may restrict operational adaptability and increase compliance costs. The market's reliance on pivotal industries such as ceramics, electronics, and automotive renders it susceptible to fluctuations in these sectors, thereby affecting demand consistency. The emergence of alternative materials and cutting-edge technologies also presents a competitive threat, as they might outshine conventional specialty alumina uses. Furthermore, the slow evolution of technological advancements in manufacturing techniques can hinder innovation and limit the introduction of new offerings. Nevertheless, the Specialty Alumina Market possesses a robust foundation, driven by expanding uses in advanced materials and energy-efficient technologies. The rising focus on sustainable solutions and practices creates avenues for market participants to innovate and adjust, potentially enhancing growth within the industry. Through strategic investments and efforts to navigate these challenges, the market is well-positioned for a bright future.

Segments of the Specialty Alumina Market

By Type

- Aluminium

- Trihydroxide (ATH)

- Activated Aluminas

- Boehmite

- Calcined Alumina

- Tabular Alumina

- Fused Alumina

By Application

- Mining

- Chemical Industry

- Architecture

- Automobile

- Aerospace & Defense

- Electric Appliances

- Other

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America