Servo Motors And Drives Market Analysis and Insights:

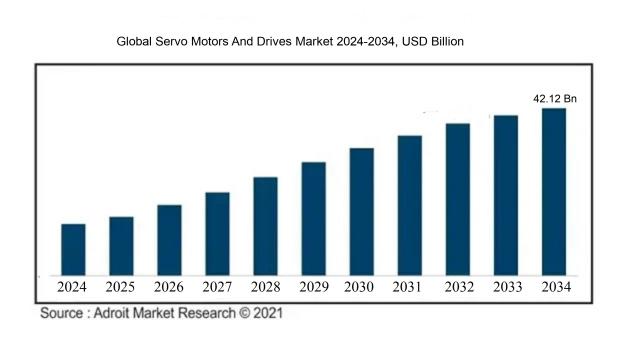

The size of the worldwide market for servo motors and drives was USD 22.04 billion in 2024, increased to USD 24.06 billion in 2025, and is projected to reach around USD 42.12 billion by 2034, with a compound annual growth rate (CAGR) of 7.10% from 2024 to 2034.

The market for servo motors and drives is significantly influenced by the surge in automation across various sectors such as manufacturing, robotics, and aerospace, which require high precision and effectiveness in motion control systems. An increasing focus on energy efficiency and sustainability is driving the adoption of advanced servo technologies, noted for their lower power consumption in comparison to conventional systems. The rise of the Internet of Things (IoT) and initiatives aimed at smart manufacturing are improving connectivity and data integration, further stimulating the demand for advanced servo solutions. Moreover, innovations in manufacturing practices and the escalating use of automation in developing economies are supporting market expansion. The industry’s pursuit of ened productivity and enhanced operational efficiency is also prompting investments in cutting-edge servo motors and drives, establishing them as critical elements in ushering the next phase of industrial evolution.

Servo Motors And Drives Market Definition

Servo motors are a type of electric motor engineered for meticulous regulation of either angular or linear position, speed, and acceleration. In contrast, servo drives are electronic components that manage servo motor functions by delivering the necessary power and fine-tuning performance in accordance with feedback signals.

Servo motors and drives are vital components across numerous applications because of their accuracy and effectiveness in motion control. They are indispensable for automation in sectors like robotics, manufacturing, and aerospace, where precise positioning and speed regulation are paramount. These motors deliver substantial torque and rapid response times, facilitating seamless execution of complex tasks. When paired with advanced drive systems, they improve both performance and energy efficiency, leading to lowered operating expenses. Additionally, their versatility in various environments and ability to seamlessly integrate with control architectures further contribute to their importance in contemporary engineering, fostering innovation and enhancing productivity across multiple industries.

Servo Motors And Drives Market Segmental Analysis:

Insights On Product Type

Rotary Servo Motors

Rotary Servo Motors, particularly Continuous Rotation Type, are anticipated to dominate the Global Servo Motors and Drives Market. The rise in automation across various industries such as manufacturing, automotive, and robotics is leading to increased demand for rotary applications. Continuous rotation motors offer versatile functionalities, allowing for constant movement in a circular pattern which is crucial in applications requiring smooth and uninterrupted motion. Additionally, the technological advancements enhancing performance and efficiency further bolster their market presence. The expansive scope for usage in areas such as packaging, conveyor systems, and CNC machines reinforces the leadership of Rotary Servo Motors in the industry landscape.

Linear Servo Motors

Linear Servo Motors are gaining traction, primarily due to their ability to provide precise linear motion without the requirement of mechanical transmissions such as gears or belts. This leads to a reduction in maintenance costs and an increase in overall system reliability. Application in industrial automation and process control are notably on the rise, with the equipment requiring high speed and accuracy. Despite not being as prevalent as rotary types, the unique advantages of linear motors, especially in applications where space is constrained, allow them to carve out a significant market presence.

Positional Rotation Type

Positional Rotation Type Rotary Servo Motors occupy an essential niche within the market. They excel in applications that require precise control of angular positioning, making them ideal for robotics and automated assembly lines. Their ability to provide high torque at low speeds is favorable for applications necessitating exact movements. Nonetheless, the growth of this category is hindered by the faster adoption of Continuous Rotation Types due to their broader application scope and operational flexibility, which influences market dynamics overall.

Continuous Rotation Type

Continuous Rotation Type Rotary Servo Motors stand out for applications that require relentless and smooth circular movement. They are widely utilized due to their adaptability in various settings, from simple toys to complex industrial machinery. The demand for automated solutions is highly boosting this, as they are integral in conveyor systems and robotic arms. Their straightforward design allows for fewer mechanical failures, promoting a steady rise in preference for Continuous Rotation Types in numerous applications across diverse industries, thus enhancing their market footprint significantly.

Insights On Technology

Multi-Axis Servo Systems

The Global Servo Motors and Drives Market is predominantly expected to be dominated by Multi-Axis Servo Systems. This is largely driven by their capability to manage complex movements and their extensive applications in automation and robotics. Industries such as manufacturing, automotive, and aerospace are increasingly turning to Multi-Axis systems due to their efficiency in precision control and higher productivity. The demand for automation in various sectors needs a cohesive and synchronized operational flow, which Multi-Axis systems efficiently provide. This growing emphasis on Industry 4.0 and smart manufacturing further positions Multi-Axis systems at the forefront of market growth.

Single-Axis Servo Systems: Pulse Duty Servo Drives

Pulse Duty Servo Drives have their unique appeal, particularly in applications requiring straightforward motion control and where cost efficiency is key. Their structure allows for quick control adjustments and is often utilized in systems where frequent starts and stops occur. Industries still rely on Pulse Duty Servo Drives for specific non-continuous applications, ensuring a notable market presence. However, while innovative, their single-axis limitation restricts their use in more complex automation settings, which may hinder growth prospects compared to Multi-Axis alternatives.

Single-Axis Servo Systems: Continuous Duty Servo Drives

Continuous Duty Servo Drives excel in environments requiring prolonged and uninterrupted operation, which is particularly vital in industries such as manufacturing and robotics. These systems typically provide a higher torque option and can handle a consistent workload efficiently over extended periods. The reliability and robustness of Continuous Duty Servo Drives make them favorable for applications wherein high performance must be maintained without fluctuations. However, like Pulse Duty Drives, they may not provide the same versatility as Multi-Axis systems in more intricate operations, impacting their overall market dominance.

Insights On Application

CNC Machines

CNC Machines are expected to dominate the Global Servo Motors and Drives Market due to their wide application in manufacturing industries where precision and accuracy are paramount. The increasing demand for automated solutions and the need for high-quality output has led manufacturers to adopt CNC technology. servo motors play a crucial role in enhancing the performance of CNC machines by providing the necessary torque, speed, and precision. The rise in industrial automation, coupled with advancements in CNC technology to improve efficiency and reduce operational costs, further propels the growth of this. Additionally, the growing trend of smart manufacturing and the implementation of Industry 4.0 practices are driving investment in CNC machine technology, solidifying its position in the market.

Robotics

Robotics is gaining traction in the Global Servo Motors and Drives Market owing to the increasing adoption of automation across various industries, including automotive, healthcare, and logistics. Robots rely heavily on servo motors for precise control of movement and execution of tasks, enabling them to perform complex operations with accuracy. As countries and companies shift towards automation to enhance efficiency and productivity, the demand for robotic applications is surging. Innovations in robotics technology, particularly collaborative robots (cobots), which can work alongside humans, are further contributing to the growth of this sector.

Electronic Devices

The of Electronic Devices is also showing considerable potential within the Global Servo Motors and Drives Market. The rapid growth of consumer electronics, including cameras, drones, and smart home appliances, is driving the demand for compact and efficient servo motors that assure high performance. As the trend for miniaturization continues, manufacturers are focusing on developing smaller, more efficient motors with enhanced features, benefiting electronic devices as they require precise control for better functionality. Moreover, as technology evolves, innovations such as IoT-enabled devices have led to an increased need for sophisticated motion control solutions.

Remote Controlled Toys

The market for Remote Controlled Toys utilizes servo motors for their ability to deliver responsive, precise movement essential for enhancing user experience. Despite being a smaller compared to CNC machines or robotics, the demand for remote-controlled vehicles, drones, and other toys continues due to their popularity among consumers. With advancements in technology, manufacturers are now able to offer improved control and better battery efficiency in remote-controlled toys, allowing for more dynamic features. This benefits from continuous customer interest and investment into enhancing playability through servo motor innovation.

Other Industrial Machinery & Equipment

The category of Other Industrial Machinery & Equipment encompasses a variety of applications that rely on servo motors for optimal operation, including conveyor systems, packaging machines, and assembly lines. The broad spectrum of industries utilizing these technologies, such as manufacturing, food and beverage, and pharmaceuticals, ensures a steady demand for robust and efficient motor solutions. With industries focusing on improving efficiency and reducing downtime through automated machinery, the reliance on servo motors in these applications remains strong, driven by the need for reliability and precision in operational tasks.

Insights On Motor Configuration

Brushless DC Motors

Brushless DC Motors are expected to dominate the Global Servo Motors and Drives Market due to their superior efficiency, reliability, and performance in various industrial applications. These motors offer enhanced control over speed and torque, along with minimal maintenance requirements due to the absence of brushes, which typically wear down in traditional systems. The growing demand for automation and robotics in manufacturing and other sectors is propelling the adoption of Brushless DC Motors. Additionally, their compact design and lightweight nature make them favorable for applications requiring space optimization, further enhancing their appeal in the market.

Induction Type

Induction Type motors are widely recognized for their ruggedness and ability to operate in various environments. They are popular in industrial applications that require reliability and minimal maintenance costs over time. Their simplicity and cost-effectiveness make them a frequently chosen option. Although they might not match the performance efficiency of other motor types like Brushless DC, they are suitable for large-scale operations, including pumps and fans, where constant speed is essential. The growing trend toward automation may keep Induction Type motors relevant, particularly in manufacturing setups seeking robust solutions.

Synchronous Type

Synchronous Type motors are distinguished by their ability to maintain constant speed regardless of load changes, making them ideal for applications that necessitate high precision and timing. Their capacity for high efficiency at various operational levels is increasingly recognized, particularly in sectors demanding meticulous performance, such as aerospace and robotics. As industries progressively focus on energy efficiency and environmental sustainability, the interest in Synchronous Type motors is likely to rise. The combination of performance and reliability supports their place in specialized applications, although they may not outpace the dominant Brushless DC category overall.

Separated Excited DC Motors

Separated Excited DC Motors are valued for their excellent speed control and torque characteristics, common traits sought after in applications requiring high adaptability to different conditions. These motors find use in various industries such as robotics, conveyors, and electric vehicles due to their dynamic performance. Despite their higher maintenance needs compared to Brushless DC and Synchronous motors, they can still meet specific application demands. However, their overall market share is gradually declining as industries shift towards more advanced technologies that offer greater efficiency with lower operational costs, such as modern brushless solutions.

Permanent Magnet DC Motors

Permanent Magnet DC Motors provide notable advantages, particularly in performance and efficiency for applications demanding high torque in a compact design. They are commonly employed in electric vehicles and portable equipment where energy conservation and battery life are critical. However, the presence of alternatives with advanced features and reduced maintenance demands has resulted in increased competition. While there remains a niche market for Permanent Magnet DC Motors, their growth is tempered by customer preferences shifting towards technologies like Brushless DC motors that offer superior reliability and efficiency in a broader range of applications.

Insights On Rated Power Capacity

1 to 5 kW

The 1 to 5 kW category is expected to dominate the Global Servo Motors and Drives market due to its wide applicability across various industries, including robotics, CNC machines, and automation systems. This range strikes a balance between power and efficiency, making it ideal for smaller-scale operations that require precise motion control. Industries increasingly demand compact yet powerful solutions for automation, driving the need for motors within this capacity. Additionally, advancements in technology have led to improvements in performance and reliability in this range, further solidifying its leading position as manufacturers prioritize efficiency and effectiveness in their systems.

400 to 750 kW

The 400 to 750 kW range caters to heavy-duty applications often found in sectors such as manufacturing, oil and gas, and material handling. This capacity range is essential for operations requiring robust power and is often integrated into large machinery and systems. While it is not the largest in terms of capacity, its capability to meet the high torque requirements of industrial processes makes it a vital component in production lines and other large-scale applications.

750 to 1 kW

The 750 to 1 kW range typically serves specialized applications and environments where moderate power levels are necessary, but extensive capabilities are not required. It finds use in small industrial machines, HVAC systems, and automation tasks in controlled environments. As industries strive for energy efficiency, this capacity is increasingly appealing for its balanced power output and operational cost-effectiveness, supporting applications that demand moderate yet reliable performance.

15 to 50 kW

Operating in the 15 to 50 kW range, motors cater primarily to mid-sized applications. Industries benefit from this power capacity due to its versatility, often suited for packaging machinery, conveyor systems, and textile processing. This range strikes a good compromise between cost and power output, making it favorable for manufacturers looking to optimize their operations without excessive investment in larger motors, while still ensuring robust performance for various intermediate tasks.

50 to 100 kW

The 50 to 100 kW capacity is pivotal in bridging the gap between mid-range and heavy-duty applications. It is particularly significant in environments that require precise control and substantial power, such as robotics and advanced manufacturing processes. Though it does not dominate the overall market, its relevance is underscored in applications like servo-driven presses and high-performance machinery, providing flexibility and high responsiveness necessary for modern industries aiming for increased productivity and efficiency.

Global Servo Motors And Drives Market Regional Insights:

Asia Pacific

The Asia Pacific region is projected to dominate the Global Servo Motors and Drives market due to a combination of rapid industrialization, increasing demand for automation, and significant growth in manufacturing sectors, particularly in countries like China, Japan, and India. With a substantial focus on smart manufacturing and IoT applications, the region's investments in robotics and automation technologies are driving a surge in servo motor applications. Further, the rapid growth of industries such as automotive, electronics, and food processing is also propelling the demand for high-performance servo motors. As a result, Asia Pacific is expected to lead the market share, supported by favorable government initiatives and global supply chain diversification.

North America

North America holds a significant position in the Global Servo Motors and Drives market, primarily driven by the presence of advanced manufacturing facilities and a strong technological landscape. The region has a high adoption rate of automation solutions, owing to the need for enhanced productivity and efficiency in manufacturing processes. The automotive industry, along with aerospace and defense, is a key sector driving demand, as companies seek to integrate cutting-edge servo technologies into their systems. Moreover, ongoing investments in R&D and the development of advanced applications further bolster the market in this region.

Europe

Europe stands as a pivotal region in the Global Servo Motors and Drives market, characterized by its strong commitment to innovation and sustainability in manufacturing. European countries are focusing on Industry 4.0 initiatives, promoting smart factories that heavily rely on servo motors for precise control systems. The automotive and machinery sectors are the leading consumers of these technologies, facilitated by stringent regulations aimed at improving energy efficiency and reducing emissions. Additionally, the presence of major market players in Western Europe enhances the competitive landscape, supporting continued growth and advancement in servo solutions.

Latin America

Latin America offers a burgeoning market for Servo Motors and Drives, driven by increasing investments in automation and technology adoption across various industries such as mining, agriculture, and manufacturing. Countries like Brazil and Mexico are witnessing a gradual shift toward modernized industrial processes, albeit at a slower pace compared to other regions. The growing emphasis on enhancing productivity and operational efficiency is likely to fuel the demand for servo motors. However, economic challenges and fluctuations may hinder growth potential, necessitating a careful approach to market penetration and development.

Middle East & Africa

The Middle East & Africa region is expected to experience moderate growth in the Servo Motors and Drives market, primarily attributed to burgeoning industrial sectors and infrastructural developments. Countries such as the UAE and South Africa are investing in automation to enhance productivity, particularly in oil and gas, mining, and manufacturing. Nonetheless, the market faces challenges related to budget constraints and varying levels of industrial maturity within the region. Increased focus on innovation and technology adoption will play a crucial role in determining the market's future trajectory as industries strive to improve their operational capabilities.

Servo Motors And Drives Competitive Landscape:

Major contributors in the worldwide Servo Motors and Drives market play a crucial role in fostering innovation and advancing technology, thereby improving performance and energy efficiency. They are dedicated to broadening their product lines and forming strategic alliances to meet a wide array of industrial needs.

Prominent entities in the Servo Motors and Drives sector encompass Siemens AG, Rockwell Automation, Inc., Mitsubishi Electric Corporation, Schneider Electric SE, Fuji Electric Co., Ltd., Yaskawa Electric Corporation, ABB Ltd., Bosch Rexroth AG, Panasonic Corporation, Emerson Electric Co., Kollmorgen Corporation, Omron Corporation, Nidec Corporation, Delta Electronics, Inc., and Lenze SE.

Global Servo Motors And Drives COVID-19 Impact and Market Status:

The Covid-19 pandemic caused significant disruptions in supply chains and manufacturing operations, resulting in a short-term decline in the Global Servo Motors and Drives market. Concurrently, it hastened the integration of automation and advanced technologies across a range of sectors.

The COVID-19 pandemic had a profound impact on the servo motors and drives sector, leading to both challenges and necessary adjustments. At the onset, global supply chains were disrupted due to lockdowns and mandates, resulting in production delays and diminished demand across several industries, particularly in automotive and manufacturing. Conversely, the increased emphasis on automation and robotics to ensure contactless operations and enhance efficiency led to a ened need for servo motors and drives in fields such as healthcare and logistics. Furthermore, the trend towards remote work, along with a growing investment in smart manufacturing, has spurred a focus on upgrading automated systems. Looking ahead, the market is expected to rebound, bolstered by continuous technological innovations and an increasing emphasis on energy-efficient solutions that are critical for sustainable industrial practices. In summary, the pandemic has hastened the shift towards automation, thereby transforming the servo motors and drives market into one that is more robust and innovative.

Latest Trends and Innovation in The Global Servo Motors And Drives Market:

- In July 2021, Siemens announced the acquisition of RTS (Real Time Systems), which specializes in software solutions for industrial automation, enhancing Siemens' capabilities in servo motor and drive solutions.

- In April 2022, Mitsubishi Electric launched the MELSERVO-J5 series of servo drives, which include advanced features such as eco-friendly design and enhanced control algorithms for improved energy efficiency.

- In October 2022, Rockwell Automation acquired Plex Systems, a cloud-native smart manufacturing platform, to enhance their manufacturing execution systems, aligning this with their Allen-Bradley servo motors and drives portfolio.

- In March 2023, Bosch Rexroth introduced the ctrlX DRIVE, a modular and scalable drive system that allows for the integration of various drive types, including servo drives, enabling customers to customize solutions for their automation needs.

- In July 2023, Schneider Electric completed the acquisition of AVEVA Group, aimed at enhancing the integration of electrical and mechanical systems, thereby improving the performance of their servo motor and drive offerings in industrial applications.

- In August 2023, Yaskawa Electric Corporation released an updated version of their Sigma-7 series servo motors, featuring improved communication protocols for better integration with industry 4.0 frameworks.

- In September 2023, Fanuc Corporation announced a partnership with Siemens to develop integrated solutions combining their servo drive technologies, aiming to provide streamlined automation solutions across various sectors.

- In October 2023, Emerson Electric acquired a leading manufacturer of servo motors and drives, reinforcing its position in the market and emphasizing its commitment to developing more energy-efficient products for industrial automation applications.

Servo Motors And Drives Market Growth Factors:

The expansion of the Servo Motors and Drives Market is propelled by the increasing adoption of automation in manufacturing operations, along with a growing need for precise motion control in diverse sectors.

The expansion of the Servo Motors and Drives Market is chiefly fueled by a ened need for automation across multiple sectors, particularly in manufacturing, automotive, and electronics. Industries are increasingly prioritizing efficiency and precision, and servo motors along with drives offer enhanced control, accuracy, and performance, making them vital components in robotics and CNC machinery. Moreover, ongoing technological advancements, such as the emergence of advanced control systems and the integration with the Internet of Things (IoT), further augment the functionality and desirability of these products. The growing focus on energy efficiency is another significant factor driving market demand, as contemporary servo systems are engineered to operate with reduced power consumption while maintaining high performance levels. Additionally, the rise of renewable energy alternatives, especially wind and solar, creates a demand for sophisticated motion control solutions, thereby stimulating market growth. The geographic proliferation of emerging economies, where there is an upswing in manufacturing and infrastructure projects, also plays a crucial role in this market's expansion. Furthermore, intensified investment in research and development propels innovation, resulting in the creation of next-generation servo technologies that meet the shifting needs of customers and broaden market prospects. In summary, the interplay of technological progression, trends in automation, and various economic dynamics significantly influences the vigorous growth of the servo motors and drives market.

Servo Motors And Drives Market Restaining Factors:

The primary challenges hindering the Servo Motors and Drives market involve the substantial initial investment required and the intricacy of incorporating these systems into pre-existing setups.

The market for servo motors and drives encounters a number of factors that may impede its advancement. A major obstacle is the substantial initial investment required for the acquisition and installation of cutting-edge servo systems, which often deters small and medium enterprises from embracing this technology. Moreover, the difficulty of integrating these advanced systems with pre-existing infrastructure can create challenges, especially in sectors dependent on older machinery. Additionally, variability in raw material prices may influence production expenses, which can consequently affect pricing strategies and profit margins for producers. The industry also faces a scarcity of qualified personnel proficient in the operation and maintenance of advanced servo systems, which poses a constraint on market growth. Regulatory barriers, along with safety and energy efficiency standards, may further limit new product development and market entry for emerging companies. Nonetheless, the escalating demand for automation and precise control within manufacturing processes is propelling innovation and investment in this field. As various industries increasingly acknowledge the benefits of servo technology in boosting productivity and minimizing operational costs, the servo motors and drives market is poised to navigate these challenges and achieve significant growth in the near future.

Key Segments of the Servo Motors and Drives Market

By Product Type

- Linear Servo Motors

- Rotary Servo Motors

- Positional Rotation Type

- Continuous Rotation Type

By Technology

- Single-Axis Servo Systems

- Pulse Duty Servo Drives

- Continuous Duty Servo Drives

- Multi-Axis Servo Systems

By Application

- Remote Controlled Toys

- Robotics

- Electronic Devices

- CNC Machines

- Other Industrial Machinery & Equipment

By Motor Configuration

- AC Servo Motors

- Induction Type

- Synchronous Type

- DC Servo Motors

- Brushless DC Motors

- Separated Excited DC Motors

- Permanent Magnet DC Motors

By Rated Power Capacity

- 400 to 750 kW

- 750 to 1 kW

- 1 to 5 kW

- 15 to 50 kW

- 50 to 100 kW

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America