Market Analysis and Insights:

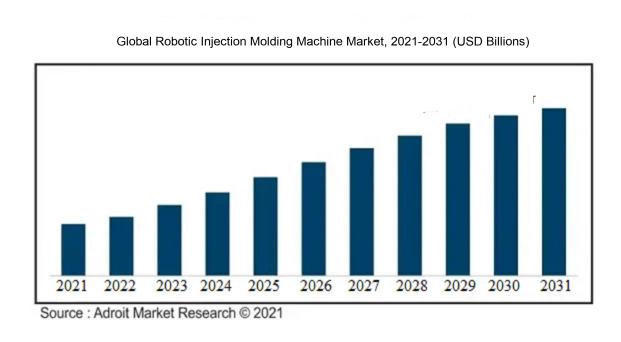

The market for Global Robotic Injection Molding Machine was estimated to be worth USD XX billion in 2021, and from 2021 to 2031, it is anticipated to grow at a CAGR of XX%, with an expected value of USD XX billion in 2031.

The global market for robotic injection molding machines is being propelled by various significant factors. An increasing demand for efficient and cost-effective production of plastic parts is driving the uptake of these machines.

They provide ened precision and control, resulting in better product quality and reduced waste. Furthermore, the widespread incorporation of automation and robotics in different industries is boosting productivity and cutting down labor expenses. Robotic injection molding machines offer quicker cycle times and increased output rates, enabling manufacturers to cater to the rising demand for plastic components in sectors such as automotive, packaging, and electronics. The emphasis on sustainability and environmental issues is also nudging companies toward utilizing advanced technologies like robotic injection molding machines, as they curtail energy usage and minimize material wastage. Additionally, the evolution of robotic technology, including collaborative robots or cobots that can collaborate with humans, is contributing to the market's expansion. In essence, the growth of the robotic injection molding machine market is steered by the drive for enhanced productivity, cost-effectiveness, sustainability, and ongoing technological advancements in the manufacturing realm.

Robotic Injection Molding Machine Market Scope:

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2031 |

| Study Period | 2018-2031 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2031 | USD XX billion |

| Growth Rate | CAGR of XX% during 2021-2031 |

| Segment Covered | By Type, By Application, By Region. |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Fanuc Corporation, KraussMaffei Group, Wittmann Battenfeld GmbH, Yushin Precision Equipment Co., Ltd., Wittmann Group, Engel Austria GmbH, Sepro Group, Arburg GmbH + Co KG, Haitian International Holdings Limited, Stäubli International AG, Sumitomo (SHI) Demag Plastics Machinery GmbH, and Milacron Holdings Corp. |

Market Definition

A robotic injection molding machine represents a form of industrial equipment that leverages automation and robotics technology to shape plastic materials into desired forms. By integrating the accuracy and efficiency of injection molding with the benefits of robotic automation, this machinery enhances overall productivity and precision.

Robotic injection molding machines are essential in the manufacturing sector because of their various advantages and positive impact. These machines utilize advanced robotic technology to automate and enhance the injection molding process, ultimately boosting efficiency, productivity, and accuracy.

Through the integration of robotics, they are capable of executing intricate tasks with precision, reliability, and speed, leading to the production of superior quality items and reduced material wastage. Additionally, robotic injection molding machines play a crucial role in improving workplace safety by reducing workers' exposure to dangerous substances and repetitive actions. In summary, these machines are instrumental in streamlining manufacturing operations, enhancing product excellence, and fostering a safer and more effective work environment.

Key Market Segmentation:

Insights On Key Type

Servo Sprue Pickers

Servo Sprue Pickers are expected to dominate the Global Robotic Injection Molding Machine Market. These robots are specifically designed to efficiently extract the sprue, which is the excess material that forms during the injection molding process. With their high precision and ability to handle a wide range of sprue sizes, servo sprue pickers offer enhanced productivity and cost-effectiveness. Their advanced servo-driven technology allows for precise positioning and swift operation, ensuring minimal downtime and increased efficiency in the manufacturing process. Considering the increasing demand for high-quality molded products and the need for automated solutions in the injection molding industry, it is anticipated that servo sprue pickers will dominate the market.

3 to 6 Axis Robots

3 to 6 Axis Robots also play a significant role in the Global Robotic Injection Molding Machine Market. These robots offer versatility and flexibility in various applications, including material handling, part removal, and assembly. They are capable of performing multi-axis movements, allowing for complex and precise operations. With their ability to handle different part sizes and shapes, 3 to 6 Axis Robots are widely utilized in the injection molding industry. While they may not dominate the market like servo sprue pickers, their presence and importance cannot be overlooked.

Side Entry Robots

Side Entry Robots are another essential machine in the Global Robotic Injection Molding Machine Market. They are specifically designed for injection molding machines with a side-entry mold configuration. These robots offer efficient part removal and stacking capabilities. With their ability to handle high-speed operations, side entry robots are particularly suitable for large-volume production lines. Although they may not have as broad an application range as 3 to 6 Axis Robots or the precision of servo sprue pickers, side entry robots are crucial for specific injection molding processes.

Pneumatic Sprue Pickers

Pneumatic Sprue Pickers are a type in the Global Robotic Injection Molding Machine Market that provides cost-effective solutions for sprue extraction. These robots are driven by pneumatic power and are widely used in applications where simplicity and affordability are prioritized. While they may not dominate the market due to their limitations in terms of precision and advanced functionality, pneumatic sprue pickers are preferred for certain low-volume production setups.

Others

The Others category consists of various robotic solutions that have specific applications in the Global Robotic Injection Molding Machine Market. These solutions may include specialized robots for specific injection molding processes, unique handling requirements, or customized automation solutions tailored to specific manufacturing needs. While it is difficult to generalize the dominating aspect of this part, it should not be disregarded as it encompasses innovative and niche robotic technologies catering to specific requirements in the injection molding industry.

Insights On Key Application

Plastic Injection Molding

Plastic injection molding is expected to dominate the Global Robotic Injection Molding Machine Market. This part involves the use of robotic machines to produce plastic products through injection molding techniques. With the increasing demand for plastic-based products in various industries such as automotive, healthcare, and consumer goods, the need for efficient and precise plastic injection molding processes has risen. Robotic injection molding machines provide greater accuracy, repeatability, and speed, making them essential in meeting the growing demand for plastic products. Additionally, the ability of robotic machines to handle complex geometries, multi-material configurations, and deliver consistent quality further solidifies plastic injection molding as the dominating part in the market.

Part Removal

Part removal is a crucial process in the injection molding industry, but it is not expected to dominate the Global Robotic Injection Molding Machine Market. This part focuses on removing finished products from the mold and is often performed manually or with the assistance of automation devices. Although the use of robotics in part removal can enhance efficiency and reduce labor costs, it does not encompass the entire injection molding process. Due to its more limited scope and reliance on other parts, such as plastic injection molding, part removal is not expected to be the dominant part in the market.

Inmold Labelling

Inmold labeling is another application of the Global Robotic Injection Molding Machine Market. It involves inserting labels into the mold before the injection molding process, resulting in the label becoming an integral part of the final product. While inmold labeling offers advantages such as enhanced product appearance, durability, and cost-effectiveness, it is not forecasted to dominate the market. The use of robotic machines in inmold labeling can streamline the process and ensure precise label placement, but it is a specific application within the larger injection molding industry. Consequently, inmold labeling is expected to have a smaller market share compared to plastic injection molding.

Other Applications

The other applications category encompasses a range of diverse applications for robotic injection molding machines that do not fall into the categories of plastic injection molding, part removal, or inmold labeling. These applications could include specialty processes or niche market requirements. However, due to the lack of specificity in the description and the varied nature of these applications, it is challenging to determine a clear dominating part within this category. The dominance of other applications will largely depend on the specific needs and demands of industries that require unique or customized injection molding solutions.

Insights on Regional Analysis:

Asia Pacific

The Asia Pacific region is expected to dominate the Global Robotic Injection Molding Machine market. This prediction is based on several factors. First, Asia Pacific has witnessed significant growth in the manufacturing sector, particularly in countries like China, Japan, and South Korea. These countries are major players in the automotive, electronics, and consumer goods industries, which are among the key end-users of robotic injection molding machines. Second, the region's large population and rising disposable income levels are driving the demand for a wide range of products, further fueling the need for efficient manufacturing processes. Furthermore, the presence of various established and emerging automation and robotics manufacturers in the region, coupled with government initiatives promoting automation and technological advancements, provide a conducive environment for the growth of the robotic injection molding machine market in Asia Pacific.

North America

In North America, the robotic injection molding machine market is witnessing steady growth. The region has a well-developed manufacturing sector, particularly in industries such as automotive, aerospace, and medical devices, which are driving the demand for automation and efficient production processes. Additionally, the increasing focus on sustainability and reducing manufacturing costs is prompting companies to adopt robotic injection molding machines. Moreover, the presence of major players in the robotics and automation industry, as well as strong research and development activities in the region, is likely to contribute to the growth of the market.

Europe

Europe is also experiencing growth in the robotic injection molding machine market, albeit at a slower pace compared to Asia Pacific and North America. The region has a strong manufacturing base, especially in industries like automotive, electronics, and plastics. This, along with the increasing need for automation and technological advancements, is expected to drive the market growth. Furthermore, the emphasis on sustainable manufacturing practices and the implementation of strict regulations pertaining to product quality and safety are also contributing to the adoption of robotic injection molding machines in Europe.

Latin America

Latin America is witnessing steady growth in the robotic injection molding machine market. The region is home to several automotive and consumer goods manufacturing companies, which are adopting automation to enhance their production efficiency. Additionally, the growing middle-class population and the increasing disposable income levels are contributing to the demand for a wide range of products, thereby driving the need for automated manufacturing processes. Moreover, the presence of government initiatives promoting industrial automation and the establishment of favorable trade policies are expected to further fuel market growth in Latin America.

Middle East & Africa

The Middle East & Africa region is expected to have limited growth in the robotic injection molding machine market. Although the region has a growing manufacturing sector, it is relatively smaller compared to other regions. The market in this region is mainly driven by countries like the United Arab Emirates, Saudi Arabia, and South Africa, which have a developed industrial base. However, factors such as less focus on automation and limited technological advancements may hinder the widespread adoption of robotic injection molding machines in the region. Despite these challenges, ongoing infrastructure development projects and the increasing emphasis on diversifying economies are expected to create opportunities for market growth in the Middle East & Africa.

Company Profiles:

Prominent entities within the worldwide robotic injection molding machine sector are at the forefront of innovation, dedicating themselves to the creation and production of cutting-edge robotic injection molding equipment. These machines serve to enhance production efficiency and drive cost savings across a spectrum of industries such as automotive, electronics, and packaging. Additionally, these key players undertake the crucial responsibility of delivering technical assistance and maintenance services to uphold the peak operational efficiency and dependability of the machinery.

Prominent companies driving the robotic injection molding machine sector encompass Fanuc Corporation, KraussMaffei Group, Wittmann Battenfeld GmbH, Yushin Precision Equipment Co., Ltd., Wittmann Group, Engel Austria GmbH, Sepro Group, Arburg GmbH + Co KG, Haitian International Holdings Limited, Stäubli International AG, Sumitomo (SHI) Demag Plastics Machinery GmbH, and Milacron Holdings Corp. These firms are acknowledged for their significant market influence and cutting-edge technological developments in robotic injection molding machines, serving a diverse array of industries including automotive, healthcare, packaging, and consumer goods. By actively pursuing strategies like mergers, strategic partnerships, and new product introductions, they aim to strengthen their market presence and provide novel solutions to their clientele.

COVID-19 Impact and Market Status:

The global market for robotic injection molding machines has experienced notable effects as a result of the Covid-19 pandemic, including supply chain disturbances and decreased demand across multiple end-use sectors.

The global economy has been significantly affected by the COVID-19 pandemic, and this impact has extended to the robotic injection molding machine market. Prior to the pandemic, the market for these machines was experiencing steady growth, driven by the increasing trend towards automation and the need for more efficient manufacturing processes. However, the emergence of COVID-19 disrupted supply chains, led to a decrease in industrial production, and reduced the demand for manufactured goods, thereby influencing the adoption of robotic injection molding machines.

While certain sectors like healthcare and packaging have seen an uptick in demand and continue to invest in automation technologies, others such as automotive and consumer goods have experienced a decline, resulting in an overall decrease in market demand. Manufacturers of robotic injection molding machines have encountered obstacles like production delays, supply chain disruptions, and reduced workforce capacity due to lockdowns and safety measures. It is anticipated that the market will gradually recover as economies reopen and industrial activities resume, although the full impact of COVID-19 on the robotic injection molding machine market remains to be fully understood.

Latest Trends and Innovation:

- In January 2021, Wittmann Battenfeld, a leading manufacturer of injection molding machines, acquired FarragTech GmbH, a German producer of robotic systems for injection molding.

- In February 2021, Fanuc Corporation announced the launch of its new all-electric injection molding machine, Roboshot α-S150iA, featuring enhanced precision and efficiency.

- In March 2021, Sumitomo (SHI) Demag Plastics Machinery GmbH introduced their new IntElect 500 electric injection molding machine, offering improved performance and energy efficiency.

- In April 2021, Yushin Precision Equipment Co. Ltd. acquired HB-Therm Group, a Swiss company specializing in temperature control solutions for the plastics industry.

- In May 2021, KraussMaffei Group GmbH announced its merger with Hirschmann Laborgeräte GmbH & Co. KG, a German manufacturer of laboratory equipment, to expand its product portfolio in the field of laboratory automation.

- In June 2021, Sepro Group, a leading manufacturer of robots for the plastics industry, introduced the MySepro i4.0 software platform, enabling real-time monitoring and optimization of injection molding processes.

- In July 2021, Milacron Holdings Corp., a leading manufacturer of plastics processing equipment, announced its acquisition by Hillenbrand Inc., a global diversified industrial company.

- In August 2021, Arburg GmbH + Co KG launched the next generation of its hybrid Allrounder injection molding machines, offering increased precision, productivity, and flexibility.

- In September 2021, Engel Austria GmbH unveiled its e-speed 280/100 hybrid injection molding machine, featuring high energy efficiency and precision in fast-cycling applications.

- In October 2021, Husky Injection Molding Systems Ltd. introduced its next-generation Ultra Helix valve gate technology, designed to improve part quality and reduce production costs.

- In November 2021, Nissei Plastic Industrial Co. Ltd. announced the development of its TACT5 injection molding machine controller, featuring enhanced usability and productivity.

- In December 2021, Haitian International Holdings Limited acquired Zhafir Plastics Machinery GmbH, a German manufacturer of electric injection molding machines, expanding its global presence and product portfolio.

Significant Growth Factors:

Factors driving the expansion of the Robotic Injection Molding Machine Market encompass the increasing requisition for automation in manufacturing operations, the necessity for improved accuracy and effectiveness, and the escalating embrace of robotics across diverse sectors.

The market for robotic injection molding machines is set to experience notable growth due to a variety of impactful factors. Initially, the rising demand for automation and efficient manufacturing processes is propelling the utilization of robotic injection molding machines. These machines offer increased productivity, precision, and repeatability, resulting in reduced cycle times and enhanced output quality. As a result, they are being extensively adopted by industries such as automotive, packaging, and consumer goods. Additionally, the increasing emphasis on cost-effective and sustainable manufacturing solutions is contributing to market expansion. Robotic injection molding machines have the ability to optimize material usage, decrease waste, and lower energy consumption, making them an appealing option for companies seeking to bolster their sustainability initiatives and profitability simultaneously.

Furthermore, advancements in robotic technology, including artificial intelligence and machine learning, are driving the evolution of more sophisticated and intelligent injection molding machines. These machines can self-optimize their processes, conduct real-time quality assessments, and facilitate predictive maintenance, further promoting their adoption.

Furthermore, the rise in investments in research and development endeavors by major market players to enhance the capabilities and functionalities of robotic injection molding machines is predicted to bolster market growth. Finally, the growth of the manufacturing sector in emerging economies, along with government efforts to encourage industrial automation, is creating lucrative prospects in the market. In summary, these drivers are anticipated to propel the expansion of the robotic injection molding machine market in the forthcoming years.

Restraining Factors:

Constraints such as the scarcity of proficient operators and the substantial upfront financial outlays serve as impediments to the expansion of the Robotic Injection Molding Machine Market.

The market for robotic injection molding machines has seen significant growth in recent years, though it faces various challenges that could hinder its advancement. One key obstacle is the high initial investment required to acquire these machines, which can be a major deterrent for small and medium-sized enterprises looking to adopt this technology. Additionally, the intricate nature of robotic injection molding machines necessitates skilled technicians for their operation and maintenance, resulting in ened training and labor expenses. Moreover, traditional molding manufacturers may be reluctant to embrace new technologies due to concerns about the need to overhaul their current manufacturing processes and retrain their workforce. The absence of industry standards adds another layer of complexity for end-users trying to navigate between different machines and suppliers.

Furthermore, the increasing emphasis on sustainability and environmental concerns related to plastic usage could also impact the market's growth trajectory. Nevertheless, there are positive prospects for the Robotic Injection Molding Machine Market. Ongoing technological advancements, such as the incorporation of artificial intelligence and machine learning, are anticipated to enhance the efficiency and capabilities of these machines. Continued research and development endeavors aimed at streamlining the cost and complexity of robotic injection molding machines may facilitate broader adoption among various businesses. The industry's growing focus on sustainability is likely to drive increased utilization of these machines, as they offer opportunities to optimize production processes and minimize waste. By implementing effective strategies and making the right investments, the Robotic Injection Molding Machine Market can navigate these hurdles and sustain its growth in the coming years.

Key Segments of the Robotic Injection Molding Machine Market

Type Overview

• 3 to 6 Axis Robots

• Side Entry Robots

• Servo Sprue Pickers

• Pneumatic Sprue Pickers

• Others

Application Overview

• Plastic Injection Moulding

• Part Removal

• Inmold Labelling

• Other Applications

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America