Propylene Market Analysis and Insights:

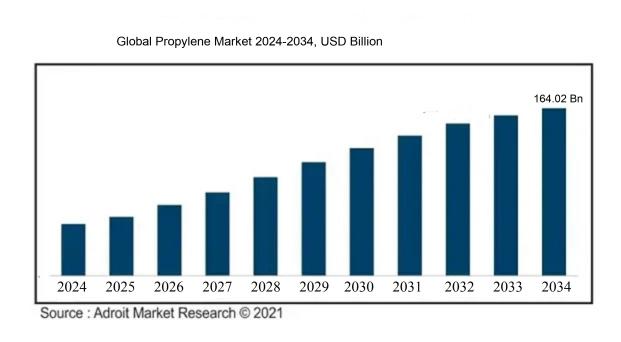

At a compound annual growth rate (CAGR) of 5.07%, the worldwide propylene market is expected to rise from its 2024 valuation of USD 115.01 billion to around USD 164.02 billion by 2034.

The propylene market is largely influenced by the growing need from the plastics and chemicals sectors, especially in the production of polypropylene, which finds extensive application in packaging, automotive components, and various consumer products. The expansion of the construction and automotive industries further drives the demand for propylene derivatives, known for improving material characteristics and lowering manufacturing expenses. Moreover, the burgeoning middle class in developing nations increases the consumption of consumer products, thereby ening the need for propylene. Innovations in production methods, like propane dehydrogenation (PDH) and steam cracking, enhance operational efficiency and economic feasibility, facilitating propylene manufacturing. Additionally, stringent environmental regulations promoting the adoption of lighter and more sustainable materials significantly boost the use of propylene. The market is also affected by geopolitical factors, including fluctuations in oil prices and changes in trade policies, which impact supply chains and ultimately influence the pricing of propylene derivatives.

Propylene Market Definition

Propylene, commonly referred to as propene, is a transparent gas and a significant hydrocarbon represented by the chemical formula C3H6. It plays a crucial role as a primary feedstock in the manufacture of a wide range of chemicals, synthetic fibers, and plastics.

Propylene, or propene, is an essential substance in the chemical sector, serving as a fundamental component in the synthesis of a variety of polymers and chemicals. This transparent gas is predominantly employed in the production of polypropylene, a material that finds extensive application in industries such as packaging, textiles, automotive manufacturing, and consumer products, owing to its strength and lightweight characteristics. Moreover, propylene acts as a precursor for significant chemicals, including acrylonitrile, propylene oxide, and isobutane, thereby enhancing its relevance across diverse fields such as construction, automotive engineering, and pharmaceuticals. Its significance is further highlighted by the increasing demand in the expanding global market focused on sustainable and recyclable materials.

Propylene Market Segmental Analysis:

Insights On Derivatives

Polypropylene

Polypropylene is expected to dominate the Global Propylene Market due to its wide array of applications across multiple industries, including packaging, automotive, textiles, and consumer goods. Its versatility, cost-effectiveness, and desirable physical properties drive substantial demand, particularly in the packaging sector where lightweight and durable materials are increasingly sought. Additionally, the growing focus on sustainability has led to innovations in polypropylene production, including recycling initiatives, further solidifying its position in the market. As a result, polypropylene is likely to maintain a significant share of the propylene derivatives market in the coming years.

Propylene Oxide

Propylene Oxide plays a critical role in the manufacturing of polyether polyols, which are essential for producing polyurethane foams, elastomers, and coatings. With the increasing demand for these products in construction, automotive, and consumer goods markets, the need for propylene oxide is on the rise. Technological advancements in production processes and the push for more eco-friendly materials will likely enhance its application, potentially increasing its market share further.

Cumene/Phenol

The Cumene/Phenol is mainly driven by the production of phenolic resins and coatings, which are integral in numerous applications from construction materials to automotive parts. The growing demand for lightweight and high-performance materials is boosting this 's growth. Furthermore, innovations in chemical processes and rising industrialization across Asia-Pacific nations are set to support the expansion of this category in the global market.

Acrylonitrile

Acrylonitrile is primarily used in the manufacture of acrylic fibers, plastics, and resins, making it a significant player in the textiles and automotive sectors. The increased demand for durable and lightweight materials in these industries is likely to propel the growth of acrylonitrile. Additionally, its application in the production of carbon fibers reflects a growing trend towards advanced material development, further supporting its market presence.

Acrylic Acid

Acrylic Acid is essential for producing superabsorbent polymers used in products like diapers and adult incontinence products, which are experiencing rising global demand. This increasing birth rate in developing countries and a trend towards personal care products are driving growth in the acrylic acid industry. Moreover, its application in coatings and adhesives also ensures a steady market, aligning well with ongoing construction and renovation activities worldwide.

Oligomers

Oligomers are increasingly recognized for their functionality in various end-use products, including coatings, adhesives, and sealants. Their favorable properties, such as lower volatility and enhanced adhesion, are pushing their adoption in the market. As industries push for more efficient and sustainable manufacturing practices, the demand for oligomers is anticipated to increase, especially as they offer a balance between performance and environmental considerations in applications.

Alcohols

Alcohols, especially isopropanol and butanol, are widely utilized in solvents, antifreeze, and as cleaning agents. The diverse application range across industries including pharmaceuticals, personal care, and automotive has ensured a steady demand. As consumer preferences shift towards more eco-friendly and less toxic alternatives, the alcohols is expected to grow, reflecting a trend toward sustainability in chemical manufacturing.

Acrylates

Acrylates are crucial in the production of paints, coatings, and adhesives due to their superior durability and weather resistance. As these industries continue to expand, particularly with the rise in construction activities and automotive manufacturing, the demand for acrylates is likely to increase. Innovation and advances in technology for acrylate applications support their growth trajectory, making them an important area within the propylene market ecosystem.

Insights On Type

Copolymer (Block)

Copolymer, specifically block copolymers, are expected to dominate the Global Propylene Market due to their superior properties and versatility in applications. Block copolymers offer enhanced mechanical strength and processability, which make them increasingly common in industries such as automotive, packaging, and construction. These materials have strong thermal resistance and compatibility with various additives, making them essential in producing advanced products. Industries are shifting towards high-performance materials to meet consumer demands for durability and functionality, positioning block copolymers as a key player in the propylene market. The continuous technological advancements and increasing adoption of block copolymers underscore their significant growth potential in the market.

Homopolymer

Homopolymer is witnessing robust demand in the Global Propylene Market, primarily due to its cost-effectiveness and wide-ranging applications. This type of polymer offers good mechanical and thermal properties, which makes it suitable for everyday plastic products, such as containers, automotive parts, and textiles. Manufacturers appreciate its straightforward processing techniques, contributing to its widespread acceptance in diverse industries. While it may not have the versatility of copolymers, the effectiveness and affordability of homopolymer make it a reliable choice for a majority of applications, supporting its sustained relevance in the marketplace.

Copolymer (Random)

Random copolymers are gaining traction in the Global Propylene Market, mainly attributed to their unique properties that enhance material performance. These copolymers provide improved clarity, flexibility, and impact resistance compared to homopolymers. Their structure allows for varied compositions that enable customization for specific applications, particularly in packaging and consumer products. However, the overall market share of random copolymers might not rival that of block copolymers due to limitations in mechanical strength. They nonetheless play a vital role in niche applications where their properties perfectly align with industry needs, contributing to a steady demand.

Insights On Application

Injection Molding

Injection molding is expected to dominate the Global Propylene Market due to its extensive use in producing various household and industrial products, such as containers, automotive parts, and consumer goods. The versatility of injection molding allows for complex designs and efficient production processes, making it a preferred method in sectors like automotive and electronics. The growing demand for lightweight and durable materials in these industries drives the need for propylene-based polymers. Additionally, advancements in technology and innovations in molding techniques further enhance the capabilities and efficiency of this method, solidifying its leading position in the market.

Film & Sheet

Film and sheet applications represent a significant portion of the propylene market due to their use in packaging solutions and agricultural films. The demand for lightweight, flexible, and durable packaging materials aligns with consumer trends favoring convenience and sustainability. Moreover, the food and beverage industry extensively relies on film and sheet products for protecting goods and extending shelf life. Innovation in manufacturing processes, such as the development of biopolymer alternatives and improved recycling methods, also contributes to the growth in this sector, although it remains secondary to injection molding in terms of overall market share.

Raffia

Raffia applications are predominantly utilized in the production of bags, sacks, and ropes, catering to agricultural and industrial needs. While the sector experienced steady growth due to increased demand for durable packaging, it remains somewhat limited compared to more versatile applications like injection molding. The rise in e-commerce and the necessity for robust packaging solutions support raffia's market presence. However, the overall market share continues to be eclipsed by more prominent applications. This sector thus tends to play a supporting role in the larger propylene market landscape.

Fiber

The fiber application mainly serves sectors such as textiles, carpets, and home furnishings. While there is a persistent demand for synthetic fibers due to their durability and versatility, this application does not dominate the propylene market as strongly as injection molding. The growing trend toward sustainable and environmentally friendly products is challenging the fiber , as consumers seek natural alternatives. Although some growth is evident from technological advancements and improved production methods, overall dynamics indicate that this lags behind others in propylene consumption.

Blow Molding

Blow molding is primarily employed in the production of hollow plastic products such as bottles, containers, and tanks. While the shows potential growth driven by the beverage, packaging, and consumer goods industries, it does not command the market in the same way that injection molding does. Factors like the increased emphasis on lightweight packaging and sustainability are somewhat propelling blow molding forward; however, it remains impacted by environmental concerns surrounding single-use plastics. Hence, despite having its niche applications, blow molding's position in the broader propylene market is less significant than that of the leading applications.

Insights On End User

Consumer Goods

Among the various s that utilize propylene, the Consumer Goods sector is expected to dominate the Global Propylene Market. This is primarily driven by the increasing demand for everyday products made from polypropylene, which offers advantages such as lightweight, durability, and cost-effectiveness. As household items, personal care products, and other consumer goods continue to expand, propelled by rising consumer spending and urbanization, this is likely to outpace others. The trend toward sustainable packaging and recyclable materials further ens the importance of propylene in this sector, as manufacturers pivot to meet consumer preferences and regulatory demands.

Packaging

The Packaging industry remains a significant user of propylene due to its role in producing versatile materials that ensure product safety and convenience. With the rise in e-commerce and a growing emphasis on brand integrity through packaging, the demand for propylene-based materials is increasing. The shift towards sustainable packaging solutions, including recyclable and biodegradable options, also keeps this sector relevant and evolving in its use of propylene.

Electronics

In the Electronics sector, propylene plays a crucial role in manufacturing components such as insulating materials and casings. The growth of consumer electronics, propelled by advancements in technology and increased connectivity, drives demand in this industry. As electronic devices become smaller and more compact, the demand for lightweight and durable components, such as those made from polypropylene, will continue to rise, ensuring this 's ongoing relevance.

Medical

The Medical field utilizes propylene for a variety of applications, including the production of medical devices, packaging for pharmaceuticals, and laboratory supplies. The stringent regulations and quality requirements in this industry highlight the importance of using high-grade propylene materials that ensure safety and reliability. As healthcare continues to innovate and expand, particularly in response to global health challenges, the demand for propylene in medical applications is expected to remain strong.

Automotive

The Automotive sector leverages propylene in producing components like bumpers, dashboards, and interior panels due to the material's lightweight and durable nature. As vehicles transition toward more energy-efficient models, manufacturers increasingly favor materials that contribute to overall vehicle weight reduction. Innovations in automotive design that prioritize safety and fuel efficiency will likely sustain a robust demand for propylene in this industry.

Construction

In the Construction industry, propylene is increasingly utilized in the production of polymer-based materials, such as pipes and insulation. These materials offer benefits like flexibility and resistance to chemicals, which are essential for modern construction practices. As urbanization progresses and infrastructure projects intensify globally, the demand for propylene materials in construction and building applications is anticipated to grow significantly.

Textile

The Textile industry incorporates propylene in creating synthetic fibers, which are essential for various applications including clothing and industrial textiles. The trend toward durable and easy-care fabrics has led to increased interest in propylene-based textiles due to their resilience and cost-effectiveness. As consumer preferences shift towards high-performance textiles that require less maintenance, propylene's role in this field is likely to expand.

Agriculture

In Agriculture, propylene is used in products such as irrigation systems, mulch films, and agricultural containers. These applications benefit from the material's durability and versatility, which are essential in demanding agricultural environments. With the growing focus on sustainable farming practices and efficient resource management, the use of propylene products in agriculture is expected to gain traction, supporting the sector as it adapts to emerging trends.

Global Propylene Market Regional Insights:

Asia Pacific

The Asia Pacific region is expected to dominate the global propylene market due to several converging factors. This region is driven by significant growth in the chemical and petrochemical industries, particularly in countries like China, India, and Japan. The increasing demand for polypropylene across various sectors such as automotive, packaging, and textiles is a substantial contributing factor. Furthermore, strategic initiatives taken by companies in terms of capacity expansion and investment in advanced technologies in this region bolster its market hold. The rapid urbanization and rising population also further fuel the demand for propylene derivatives, making Asia Pacific the preeminent region in the global market.

North America

North America is a significant player in the global propylene market, with the United States leading due to its robust shale gas production. This abundance of natural gas liquids serves as an advantage, facilitating the cost-effective production of propylene. Strong demand from industries such as automotive and consumer goods continues to bolster growth. Furthermore, the emphasis on technological advancements and increased capacity for propylene production contributes positively to the market's outlook.

Europe

Europe's propylene market reflects a mature landscape characterized by sustainability initiatives and environmental regulations. The region is focused on transitioning towards greener technologies, which can slow down growth compared to regions experiencing rapid industrial expansion. Nevertheless, Europe remains strong in the demand for high-quality propylene derivatives particularly in automotive and packaging sectors, ensuring a steady market presence. Additionally, strategic collaborations among industry players to enhance product offerings can lead to a more competitive edge.

Latin America

Latin America has been a developing market for propylene, centered primarily around Brazil and Mexico. Despite facing challenges such as economic fluctuations and infrastructure hurdles, the market is witnessing gradual growth. The drive for increased polymer production, especially in the automotive and packaging industries, presents opportunities. However, the region's dependence on external investments and chemical imports can restrain its overall growth in comparison to more established regions, making its market position relatively modest.

Middle East & Africa

The Middle East and Africa region is experiencing an evolving propylene market largely due to its abundant oil reserves, enabling competitive pricing of petrochemical products. While there is potential for growth, especially in Gulf Cooperation Council (GCC) countries, infrastructural challenges and limited market size in certain African nations can impede rapid advancements. Efforts to expand olefins capacity and combat regional economic instability will be crucial in determining the future landscape of the propylene market in this region.

Propylene Competitive Landscape:

Prominent entities in the worldwide propylene sector, comprising leading chemical manufacturers, propel production via cutting-edge technology and strategic alliances, impacting pricing and supply dynamics. Their developments and growth initiatives shape market trajectories, addressing a wide range of applications across various industries, including automotive, packaging, and textiles.

Prominent participants in the propylene industry comprise LyondellBasell Industries N.V., ExxonMobil Chemical Company, Dow Chemical Company, INEOS Group Holdings S.A., Reliance Industries Limited, Royal Dutch Shell plc, SABIC (Saudi Basic Industries Corporation), Formosa Plastics Corporation, China National Petroleum Corporation (CNPC), and PetroChina Company Limited. Additionally, key players include BASF SE, Mitsubishi Chemical Corporation, Braskem S.A., Chevron Phillips Chemical Company, and LG Chem Ltd. Other noteworthy firms in this field are Westlake Chemical Corporation, Qatofin Company Limited, and Koch Industries, Inc. These organizations are integral to the manufacturing and distribution of propylene, significantly influencing the global market landscape.

Global Propylene COVID-19 Impact and Market Status:

The Covid-19 pandemic had a profound impact on the worldwide propylene market, leading to a reduction in demand in critical sectors like automotive and construction, while simultaneously disrupting supply chains and limiting production capabilities.

The COVID-19 pandemic had a profound effect on the propylene market, causing disruptions in supply chains and a decline in demand across multiple industries. In the early stages of the crisis, lockdowns and regulatory measures resulted in a notable slowdown in manufacturing sectors, especially automotive and consumer goods, which are significant users of propylene derivatives. This drop in demand led to short-term decreases in prices and excess inventory. On the other hand, there was a surge in the need for propylene in the production of healthcare-related items, including personal protective equipment (PPE) and sanitizers, which helped to mitigate some of the adverse impacts. Additionally, challenges arose from interruptions in the supply of feedstocks and the temporary shutdown of refineries, complicating propylene production efforts. As countries began to gradually ease restrictions, the market started to recover, fueled by a rebound in industrial activity and a growing emphasis on sustainable practices, which spurred investments in the production of propylene from renewable resources. Overall, the propylene market has demonstrated a degree of resilience, successfully navigating the evolving demands during and following the pandemic.

Latest Trends and Innovation in The Global Propylene Market:

- In April 2023, LyondellBasell Industries announced its acquisition of the polypropylene business of A. Schulman, a move aimed at expanding its capabilities in high-performance solutions for packaging and automotive applications.

- In March 2023, INEOS announced the start of upgradation works at its Grangemouth site, focusing on the improvement of propylene production efficiency through advanced catalytic processes.

- In January 2023, Braskem implemented new production technologies at its plant in La Porte, Texas, which enhanced the overall production efficiency of its polypropylene line, reducing energy consumption by 20%.

- In September 2022, ExxonMobil entered an agreement with SABIC to share technology for enhanced production processes in the petrochemical sector, particularly in propylene and its byproducts.

- In August 2022, TotalEnergies launched a new line of eco-friendly polypropylene products, which utilize biobased feedstock, reflecting the company's commitment to sustainability and innovation in the plastics market.

- In June 2022, Reliance Industries Limited initiated the construction of a new polypropylene plant in Jamnagar, India, aiming to strengthen their position in the local market and meet growing demand in Asia.

- In February 2022, the joint venture between Chevron Phillips Chemical and Qatar Petroleum announced progress on their new propylene production facility in Qatar, which is set to enhance their production capacity significantly by late 2024.

- In November 2021, Mitsubishi Chemical Corporation unveiled a breakthrough in polymerization technology that enabled a higher yield of polypropylene with a reduced carbon footprint, demonstrating their commitment to sustainable manufacturing practices.

Propylene Market Growth Factors:

The expansion of the propylene market is fueled by rising?? from the automotive and packaging sectors, coupled with innovations in manufacturing technologies.

The propylene market is set for considerable expansion due to several pivotal factors. A primary driving force behind this growth is the increasing demand for polypropylene, a multifunctional plastic widely utilized in sectors such as packaging, automotive, and consumer products. This trend underscores a broader preference for lightweight and durable materials. Additionally, the growth of end-use industries, particularly in emerging markets, intensifies this demand.

Technological advancements in propylene production, particularly methods like propane dehydrogenation (PDH), have resulted in more efficient and cost-effective manufacturing processes, thereby enhancing supply. Furthermore, ened investments in petrochemical infrastructure and facilities contribute to this market growth.

The movement towards sustainability and the principles of a circular economy are fueling the development of bio-based and recyclable propane derivatives, pushing innovation within the industry. Geopolitical elements, including trade regulations and regional production capacities, significantly affect pricing and market availability. Lastly, stringent environmental regulations aimed at lowering carbon footprints are encouraging manufacturers to adopt cleaner production methods, thereby further promoting market development. Overall, these interrelated factors highlight the significant potential for growth in the propylene market as it evolves to meet shifting consumer demands and industrial requirements.

Propylene Market Restaining Factors:

Significant limiting factors within the propylene industry comprise strict environmental regulations and varying costs of raw materials.

The propylene market encounters various challenges that impede its development. A significant issue is the unpredictability of feedstock prices, especially those of crude oil and natural gas, which can cause variations in both production expenses and market pricing. Furthermore, rigorous environmental regulations concerning chemical production and emissions create operational difficulties and elevate compliance costs for manufacturers. The emergence of alternative materials, such as bio-based propylene and different polymer feedstocks, influences demand as industries pursue more eco-friendly solutions. Additionally, global economic instability and geopolitical issues can disrupt supply chains, affecting the availability of propylene and its derivatives. There is also a potential danger of overproduction in areas where manufacturing facilities have expanded, resulting in an oversupply that may drive prices down. Nonetheless, in spite of these difficulties, the propylene market holds potential due to the growing demand from crucial applications like polypropylene, particularly in the packaging, automotive, and construction industries. Continuous technological innovations in production techniques, along with an increasing consumer focus on sustainable practices, could spur advancements and bolster market stability in the future.

Key Segments of the Propylene Market

By Derivatives:

- Polypropylene

- Propylene Oxide

- Cumene/Phenol

- Acrylonitrile

- Acrylic Acid

- Oligomers

- Alcohols

- Acrylates

- Others

By Type:

- Homopolymer

- Copolymer

- Random

- Block

By Application:

- Injection Molding

- Film & Sheet

- Raffia

- Fiber

- Blow Molding

By End User:

- Packaging

- Electronics

- Medical

- Consumer Goods

- Automotive

- Construction

- Textile

- Agriculture

- Other

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America