Market Analysis and Insights:

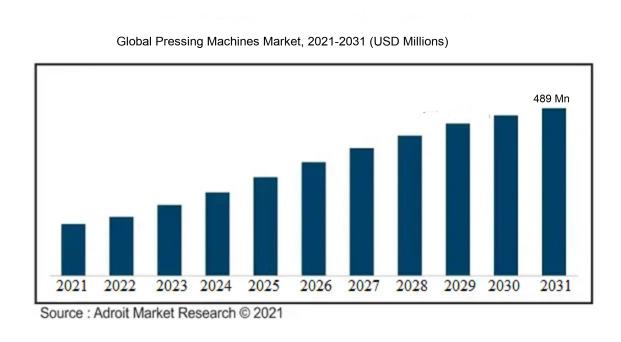

The market for Global Pressing Machines was estimated to be worth USD 219 million in 2022, and from 2023 to 2031, it is anticipated to grow at a CAGR of 7.85%, with an expected value of USD 489 million in 2031.

The market for pressing machines is being influenced by a variety of factors. One significant factor is the escalating need for effective and top-notch pressing machines in industries such as textiles, automotive, and aerospace. These machines facilitate rapid and accurate pressing operations, leading to enhanced productivity and reduced production durations. Furthermore, the increasing focus on energy conservation and sustainable manufacturing practices has prompted the incorporation of cutting-edge technologies in pressing machines, including energy-saving mechanisms and automated controls, thereby bolstering their demand. The expanding global population and the consequent surge in consumer goods requirements have also ened the necessity for efficient pressing machines to cater to the escalating production needs. Additionally, the growing penchant for customization in sectors like fashion, furniture, and electronics has resulted in a spike in demand for pressing machines that offer adaptability and versatility in operations. In essence, the pressing machines market is primarily steered by the desire for enhanced productivity, energy efficiency, and customization, exhibiting substantial growth prospects in the foreseeable future.

Pressing Machines Market Scope:

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2031 |

| Study Period | 2018-2031 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2031 | USD 489 million |

| Growth Rate | CAGR of 7.85% during 2023-2031 |

| Segment Covered | By Offering, By Application, By Region. |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Bosch Rexroth AG, Schuler AG, Komatsu Ltd., JBT Corporation, Della Toffola SpA, AP&T AB, AIDA Engineering Ltd., Baileigh Industrial Holdings LLC, HANWHA CORPORATION, and Wuxi KLT Precision Hydraulic Machinery Factory Co., Ltd. |

Market Definition

Mechanical pressing devices are crafted to exert force or pressure on substances for shaping, compressing, or heating purposes. They find wide application across sectors like manufacturing, textiles, and printing.

Pressing machines hold significant importance across various industries due to several reasons. Primarily, they play a vital role in the manufacturing sector by enabling the efficient and precise shaping of a variety of materials like metal, plastic, and textiles. These machines utilize pressure, heat, and a combination of both to mold and alter raw materials into desired shapes, sizes, and forms. Moreover, pressing machines enhance consistency and quality control during the production process, reducing the occurrence of human errors and variations. As a result, they contribute to the creation of high-quality products, minimizing waste and increasing productivity. Additionally, pressing machines are essential in the recycling industry, where they are utilized to compress and compact waste materials, simplifying their storage, transportation, and disposal. In essence, pressing machines prove to be indispensable tools that improve productivity, efficiency, and quality standards across various sectors, ensuring dependable and cost-effective production processes.

Key Market Segmentation:

Insights On Key Type

Fully-automatic

Fully-automatic is expected to dominate the Global Pressing Machines Market. This is due to its advanced features and capabilities that offer higher efficiency, productivity, and precision. Fully-automatic pressing machines are designed to operate with minimal human intervention, allowing for continuous and uninterrupted production processes. These machines are equipped with sophisticated technology and automation systems, such as PLC (Programmable Logic Controller) and HMI (Human-Machine Interface), which enable seamless operation and control. The ability of fully-automatic pressing machines to handle complex tasks with minimal errors and higher speed makes them highly desirable in various industries, including automotive, aerospace, and electronics.

Semi-automatic

While fully-automatic pressing machines are expected to dominate the market, the semi-automatic machine also holds significant importance. Semi-automatic pressing machines strike a balance between manual and fully-automatic operation. They offer certain level of automation and require minimal human effort for operation. Semi-automatic machines are often preferred in industries where occasional human intervention is needed, such as to change tooling or adjust process parameters. These machines offer versatility and flexibility, making them suitable for a wide range of applications. With their ability to provide consistent results and relatively lower investment costs compared to fully-automatic machines, semi-automatic pressing machines serve as a viable option for many businesses.

Manual

Although manual pressing machines have their place in certain niche markets, they are not expected to dominate the Global Pressing Machines Market. Manual machines rely entirely on human labor for operation, making them less efficient and prone to human errors. They require constant monitoring and manual adjustments, which can limit productivity and consistency in production processes. Manual pressing machines are commonly used in small-scale operations or specific industries where cost constraints or specialized requirements exist. However, the increasing demand for automation and the need for higher productivity have shifted the focus towards semi-automatic and fully-automatic pressing machines in the global market.

Insights On Key Application

Garment Factory

The Garment Factory is expected to dominate the Global Pressing Machines Market. Garment factories have a high demand for pressing machines as they require efficient and quick pressing of various types of garments in large quantities. The need for quality finishing and pressing in garment production is crucial, making pressing machines a vital component in garment factories. With the growing fashion industry and increasing demand for apparel products, the garment factory part is likely to dominate the market.

Clothing Stores

Clothing stores, on the other hand, may have a smaller impact on the Global Pressing Machines Market compared to garment factories. While clothing stores may require pressing machines for minor touch-ups or alterations, the volume and frequency of usage might be relatively low as compared to garment factories. Therefore, although clothing stores may contribute to the market, they are not likely to dominate the pressing machines market.

Cleaners and Dyers

Cleaners and dyers are another scope within the Application category of the Global Pressing Machines Market. While they may rely on pressing machines for their operational requirements, their overall demand might be limited as compared to garment factories. The pressing machines used by cleaners and dyers are primarily for enhancing the appearance of clothes after cleaning or dyeing processes. Hence, while cleaners and dyers play a role, they are not expected to be the dominant part.

Hotel

The Hotel application is also a player of the Application category of the Global Pressing Machines Market. Hotels often provide laundry services to their guests, and pressing machines are an essential component in their laundry departments. However, the demand for pressing machines in hotels may be relatively smaller compared to garment factories due to the different nature and scale of operations. Hence, although hotels contribute to the market, they are not likely to dominate the pressing machines market.

Other

The Other includes niche areas or applications that are not explicitly mentioned in the given options. Without further clarification or specific examples, it is challenging to determine the dominance of this part in the Global Pressing Machines Market. The Other part could include unique applications where pressing machines are essential, but without more information, it is not possible to make an accurate assessment of its dominating potential.

Insights on Regional Analysis:

Asia Pacific

Asia Pacific is expected to dominate the Global Pressing Machines market. With the increasing industrialization and growing manufacturing sector, countries like China, India, Japan, and South Korea are leading the market in terms of production and consumption of pressing machines. Asia Pacific has a large number of industries including automotive, textiles, electronics, and food processing, which are major users of pressing machines. Additionally, rising disposable income and a growing middle class in the region have also contributed to the increasing demand for consumer goods, further driving the market for pressing machines. Therefore, Asia Pacific is projected to be the dominant region in the Global Pressing Machines market.

North America

In North America, although the market for pressing machines is significant, it is projected to have a lower dominance compared to Asia Pacific. The region has an established manufacturing sector, specifically in the automotive and aerospace industries. However, the growth rate in this market is relatively slower due to the mature nature of these industries. Additionally, the recent economic downturn and the impact of the COVID-19 pandemic have also affected the market growth. Nonetheless, technological advancements and increased automation in manufacturing processes are expected to drive the demand for pressing machines in North America.

Europe

Europe also holds a significant share in the Global Pressing Machines market. The region has a strong manufacturing base, particularly in Germany, Italy, and France. The automotive, aerospace, and textile industries are major contributors to the market demand for pressing machines in Europe. However, similar to North America, the mature nature of these industries and economic challenges have impacted market growth. Nonetheless, the European Union's focus on promoting sustainable manufacturing and the adoption of advanced technologies are expected to drive the demand for pressing machines in the region.

Latin America

Latin America has the potential to witness moderate growth in the Global Pressing Machines market. The region has a diverse industrial sector, including automotive, textiles, and consumer goods. However, economic fluctuations, political instability, and infrastructure limitations have posed challenges to the market growth in Latin America. Nevertheless, the rising demand for manufactured goods and the increasing focus on improving manufacturing efficiency are expected to create opportunities for the pressing machines market in this region.

Middle East & Africa

The Middle East & Africa region is expected to have the lowest dominance in the Global Pressing Machines market. The region has a relatively smaller industrial manufacturing base compared to other regions. However, the automotive, aerospace, and construction industries in the Middle East, along with the textile industry in Africa, are driving the demand for pressing machines. The ongoing infrastructure development projects and government initiatives to diversify the economy in the Middle East, as well as the growth potential in the African textile industry, are expected to contribute to the market growth in this region.

Company Profiles:

Prominent entities in the worldwide pressing machines industry are engaged in the production and distribution of cutting-edge pressing machines tailored to diverse sectors. They are pivotal in fostering technological advancements, upholding product excellence, and fulfilling the global need for effective pressing technology.

Prominent companies in the pressing machines industry encompass Bosch Rexroth AG, Schuler AG, Komatsu Ltd., JBT Corporation, Della Toffola SpA, AP&T AB, AIDA Engineering Ltd., Baileigh Industrial Holdings LLC, HANWHA CORPORATION, and Wuxi KLT Precision Hydraulic Machinery Factory Co., Ltd. Renowned for their adept engineering and provision of top-tier pressing machinery across diverse sectors including automotive, aerospace, food and beverage, and construction, these organizations are unwavering in their commitment to innovation and product advancement. Through dedicated efforts in research and development, these industry leaders not only augment their market standing but also nurture enduring customer partnerships.

COVID-19 Impact and Market Status:

The Global Pressing Machines market has been greatly affected by the Covid-19 pandemic, leading to a decrease in demand as a result of supply chain disruptions and reduced industrial operations.

The pressing machines market has been significantly affected by the global COVID-19 pandemic. With the spread of the virus, industries worldwide have undergone temporary closures and restrictions, resulting in a downturn in manufacturing operations and a decrease in the demand for pressing machines. The pandemic's disruptive impact on the supply chain has led to delays in procuring raw materials, affecting the production capacities of pressing machine manufacturers. Furthermore, the economic slowdown and uncertainties stemming from the pandemic have prompted a reduction in investments and capital expenditures, further dampening market conditions. Nevertheless, certain markets have seen growth driven by ened demand for pressing machines in industries essential for producing goods such as food packaging and medical supplies. As manufacturing activities gradually recover and stabilize, the pressing machines market is expected to make a gradual recovery, albeit requiring time to return to pre-pandemic levels. Manufacturers are anticipated to prioritize innovation and product development to meet the evolving needs of various industries in the post-COVID-19 landscape. In summary, the pressing machines market has experienced a varied impact from the COVID-19 crisis, presenting a blend of challenges and opportunities in response to shifting market dynamics.

Latest Trends and Innovation:

- In August 2021, M&R Companies, a leading manufacturer of screen printing and digital printing equipment, acquired Novus Imaging, a company specializing in high-speed UV-LED flatbed and roll-to-roll printers.

- In June 2021, Konica Minolta Business Solutions U.S.A., Inc. announced the launch of its new MGI Meteor Unlimited Colors Series, a digital print solution that combines traditional offset printing with digital technology, offering customers a wide range of applications and high-quality reproductions.

- In May 2021, Kornit Digital, a global leader in digital textile printing technology, announced the acquisition of Custom Gateway, a software provider that offers a cloud-based platform for on-demand manufacturing and personalization of products.

- In April 2021, Xerox Holdings Corporation acquired Veenman, a multi-brand reseller of office technology solutions in the Netherlands, further expanding its presence in the European market.

- In March 2021, Heidelberg, a German manufacturer of printing equipment, announced the introduction of its Speedmaster CX 104 and CX 75 models, high-performance sheetfed offset presses that offer innovative features and enhanced productivity.

- In January 2021, Fujifilm Corporation launched the Jet Press 750S, a B2-format inkjet press that delivers high-quality printing with variable data capabilities, enabling personalized and customized printing applications.

- In December 2020, Ricoh Company announced the acquisition of DocuWare, a provider of cloud-based document management and workflow automation software, enhancing Ricoh's solutions portfolio for digital transformation and intelligent workplace services.

- In November 2020, Durst announced the expansion of its P5 technology platform with the introduction of the P5 350 HS printing system, offering high-speed production with exceptional print quality for a variety of applications.

Significant Growth Factors:

The rising need for effective and automated production processes is a key driver behind the expansion of the market for pressing machines.

The pressing machines market is seeing a notable upsurge in growth fueled by various significant factors. One primary driver is the global trend towards rapid industrialization and urbanization, which is amplifying the need for pressing machines in diverse sectors like textiles, automotive, and manufacturing. This escalating demand stems from the requirement for efficient and automated equipment that can optimize production processes, boost output, and curtail operational expenses. Moreover, there is a growing emphasis on sustainability and environmental issues, prompting the emergence of eco-friendly and energy-efficient pressing machines that resonate with environmentally conscious consumers and enterprises. Another contributing factor is the increasing popularity of customization and personalization within industries such as fashion and automotive, propelling the need for pressing machines equipped with sophisticated features to craft distinctive and top-notch products. Furthermore, the integration of cutting-edge technologies like artificial intelligence and machine learning into pressing machines is elevating market growth by enhancing precision, velocity, and automation capabilities. Lastly, the surge in disposable incomes and evolving consumer tastes is spurring the demand for well-pressed and crease-free garments, thus propelling the pressing machines market within the textile sector. In conclusion, the pressing machines market is on a robust growth trajectory driven by factors like industrialization trends, sustainability considerations, customization preferences, technological innovations, and evolving consumer behaviors.

Restraining Factors:

A key restraint in the market for pressing machines is the scarcity of skilled operators and the significant maintenance expenses associated with these machines.

The Pressing Machines Market encounters various impediments that impede its progress and advancement. A significant challenge is the substantial initial investment necessary to establish a pressing machine manufacturing facility. The expense associated with procuring and upkeeping the required machinery and technology can be significant, rendering it challenging for new entrants to join the market or for existing manufacturers to broaden their operations. Additionally, there is a scarcity of skilled labor and technicians proficient in operating these advanced machines, resulting in a skill gap within the industry. Moreover, the press machine market is subject to the cyclical nature of the manufacturing sector, meaning that during economic downturns, the demand for these machines diminishes, leading to decreased sales and profit margins. Furthermore, competition from alternative technologies like 3D printing and automation poses a challenge to the pressing machines market. Despite these obstacles, there are favorable elements to consider. The global expansion of the automotive, construction, and manufacturing sectors generates a need for pressing machines in various applications, providing avenues for market expansion. Additionally, advancements in technology within the industry, such as the creation of energy-efficient and cost-effective pressing machines, have the potential to attract customers and drive market growth. By confronting the challenges head-on and embracing innovation, the pressing machines market can surmount these restrictions and chart a course towards future prosperity.

Key Segmentation:

Type Overview

• Manual

• Semi-automatic

• Fully-automatic

Application Overview

• Garment Factory

• Clothing Stores

• Cleaners and Dyers

• Hotels

• Other

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• UK

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America