Market Analysis and Insights:

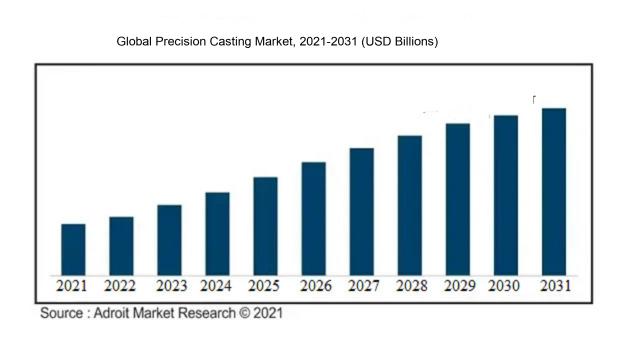

The market for Global Precision Casting was estimated to be worth USD XX billion in 2021, and from 2021 to 2031, it is anticipated to grow at a CAGR of XX%, with an expected value of USD XX billion in 2031.

The precision casting industry experiences significant growth driven by several pivotal factors. Primarily, the surge in demand for intricate, premium-quality components across sectors like automotive, aerospace, and healthcare is a primary growth driver. Precision casting enables the manufacturing of complex parts with exceptional dimensional precision and surface quality, catering to the requirements of these industries. Additionally, the escalating necessity for lightweight and fuel-efficient vehicles is boosting the adoption of precision casting as it facilitates the production of lightweight and intricate components. Furthermore, the rapid industrialization and infrastructure expansion in emerging markets contribute to market growth, with precision casting finding applications in sectors like construction and energy. Moreover, continuous technological advancements in manufacturing processes, including computer-aided design and 3D printing, are fostering market expansion by enhancing production efficiency and accuracy. In conclusion, the precision casting industry is poised for considerable growth in the foreseeable future, fueled by the increasing demand for top-notch components and the evolution of manufacturing technologies.

Precision Casting Market Scope:

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2031 |

| Study Period | 2018-2031 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2031 | USD XX billion |

| Growth Rate | CAGR of XX% during 2021-2031 |

| Segment Covered | By Offering, By Application, By Region. |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Rajesh Exports Limited, Alcoa Corporation, Precision Castparts Corporation, Amcol Metalcasting, Consolidated Precision Products Corp., Dongying Giayoung Precision Metal Co. Ltd., Hitachi Metals Ltd., Signicast LLC, Zollern GmbH & Co. KG, and Doncasters Group Limited. |

Market Definition

Precision casting, otherwise referred to as investment casting, stands as a sophisticated manufacturing technique that generates precise and detailed metal components by utilizing a wax pattern and ceramic mold. This method is esteemed for its capacity to form intricate shapes with precise tolerances and exceptional surface quality.

Precision casting, also referred to as investment casting, is a significant manufacturing technique that enables the creation of intricate metal parts with precise tolerances and excellent surface finishing. This method is widely utilized across various sectors like aerospace, automotive, medical, and defense because of its capability to fabricate complex shapes that are challenging to achieve through alternative methods. Apart from enabling the production of detailed designs, precision casting accommodates a broad range of metals, both ferrous and non-ferrous alloys. This adaptability, coupled with the capacity to manufacture highly accurate parts with superior surface quality, positions precision casting as indispensable in industries that demand top-notch components meeting stringent requirements. Moreover, this process facilitates the creation of elaborate forms while minimizing material wastage, rendering it a cost-efficient approach for yielding top-quality parts. In essence, precision casting plays a crucial role in industries requiring intricate and superior metal components by providing exceptional precision, material flexibility, and cost-effectiveness.

Key Market Segmentation:

Insights On Key Offering

Service

The Service is expected to dominate the Global Precision Casting Market. Precision casting is a complex process that requires specialized knowledge and expertise. Many companies prefer to outsource this process to service providers who have the necessary equipment, infrastructure, and skilled personnel to deliver high-quality precision castings. Outsourcing the precision casting service allows companies to focus on their core competencies and reduces the need for capital investment in casting equipment. Moreover, service providers offer consulting services, technical support, and aftersales services, which further enhance their value proposition. Therefore, the service part is expected to dominate the Global Precision Casting Market.

Equipment

The Equipment casting plays a vital role in the Global Precision Casting Market. Companies engaged in precision casting require advanced and reliable equipment to ensure accurate casting processes. The equipment includes furnaces, molds, wax injection machines, and other essential tools. Having adequate and technologically advanced equipment enhances the overall efficiency and precision of the casting process. However, while the Equipment part is significant, it is expected to be overshadowed by the Service part due to the increasing trend of outsourcing precision casting services.

Components

The Components casting also plays a crucial role in the Global Precision Casting Market. Precision castings are utilized in various industries such as aerospace, automotive, healthcare, and more. These industries require precision cast components for applications like turbine blades, engine components, medical implants, and others. The demand for high-quality components with intricate designs and precise dimensions drives the growth of the Components part. However, it is anticipated that the Service part will dominate the market as companies often prefer outsourcing the entire precision casting process rather than focusing solely on component production.

Insights On Key Application

Automotive and Transportation

The Automotive and Transportation application is expected to dominate the Global Precision Casting Market. Precision casting is crucial in the automotive and transportation industry for manufacturing complex components with high precision and accuracy. This part benefits from the increasing demand for lightweight and fuel-efficient vehicles, as precision casted parts can help reduce weight without compromising on strength. Moreover, precision casting enables the production of intricate designs and shapes required for various automotive and transportation applications. As the automotive sector continues to grow, the demand for precision casted components such as engine parts, turbochargers, and transmission systems is expected to significantly contribute to the dominance of this part in the Global Precision Casting Market.

Aerospace and Defense

The Aerospace and Defense application is anticipated to be a significant player in the Global Precision Casting Market. Precision casting plays a vital role in the aerospace and defense industry, where components need to meet stringent quality standards and withstand extreme conditions. Aerospace engines, aircraft structures, and defense equipment often require high-performance parts that can only be achieved through precision casting. Additionally, the constant innovation and development in the aerospace and defense sector drive the demand for precision casted components. The prominence of this part is expected to continue due to the continuous modernization and advancements in the aerospace and defense industry.

Oil and Gas

Although not the dominating player, the Oil and Gas sector holds substantial potential in the Global Precision Casting Market. Precision casted components are widely used in the oil and gas industry for applications such as drilling equipment, valves, pumps, and pipelines. The demand for precision casted parts in this part is driven by the need for reliable and durable components that can withstand harsh operating conditions, including high temperatures and corrosive environments. As the oil and gas industry continues to recover and expand globally, the demand for precision casted components in this part is expected to grow steadily.

Industrial Equipment

Industrial Equipment is another player that plays a significant role in the Global Precision Casting Market. Precision casting is essential in the manufacturing of industrial equipment, including machinery, tools, pumps, and various parts used in the production process. The ability to produce complex shapes and designs with high accuracy and repeatability makes precision casting an ideal choice for the industrial equipment sector. Additionally, precision casted components contribute to improved efficiency, durability, and reliability in industrial applications. The growing industrialization and modernization across various sectors worldwide drive the demand for precision casted components in this part.

Others

The Others encompasses various applications that do not fall specifically under Automotive and Transportation, Aerospace and Defense, Oil and Gas, or Industrial Equipment. This part includes niche applications such as medical equipment, power generation, consumer electronics, and telecommunications, among others. While these applications may not dominate the Global Precision Casting Market, they contribute to its overall growth. Precision casting offers benefits such as high dimensional accuracy, excellent surface finish, and the ability to create intricate designs, making it a suitable manufacturing process for specialized applications within the "Others" part. As advancements and innovations in these industries continue, the demand for precision casted components in these niche applications is likely to increase.

Insights on Regional Analysis:

Asia Pacific

Asia Pacific is expected to dominate the Global Precision Casting market. The region has been experiencing significant growth in various industries such as automotive, aerospace, and electronics, which are major consumers of precision castings. China, in particular, has emerged as a leading market for precision castings, driven by its rapid industrialization and high demand for advanced technology products. Additionally, countries like India, Japan, and South Korea are also contributing to the growth of the precision casting market in the region. The presence of key market players, favorable government initiatives, and technological advancements further support the dominance of Asia Pacific in the global precision casting market.

North America

North America is a major player in the global precision casting market. The region is home to several well-established precision casting companies, particularly in the United States. The aerospace and defense industry in North America, which requires high-quality precision castings, drives the market growth. Furthermore, the automotive and healthcare sectors in the region also contribute to the demand for precision castings. The presence of advanced manufacturing capabilities and well-developed infrastructure further strengthen North America's position in the global precision casting market.

Europe

Europe also holds a considerable share in the global precision casting market. The region is known for its robust automotive industry, which is a significant consumer of precision castings. Countries such as Germany, Italy, and France have a strong presence of precision casting manufacturers, catering to both domestic and international demand. It is worth mentioning that Europe's strict regulations regarding product quality and safety standards contribute to the preference for precision castings in various applications. Additionally, the growing emphasis on renewable energy development and the presence of leading aerospace companies further boost the demand for precision castings in the region.

Middle East & Africa

The Middle East & Africa region has a smaller share in the global precision casting market compared to Asia Pacific, North America, and Europe. However, the region's growing oil and gas industry, particularly in countries like Saudi Arabia and the United Arab Emirates, drives the demand for precision castings. Additionally, the construction and infrastructure sectors in the region are witnessing significant growth, which further contributes to the market. While the precision casting market in this region may not dominate the global market, it is expected to continue showcasing steady growth in the coming years.

Latin America

Latin America has a relatively smaller market share in the global precision casting market. Brazil, being the largest economy in the region, holds the potential for market growth due to its flourishing automotive, aerospace, and energy sectors. However, the overall market size is relatively smaller compared to other regions. Factors such as infrastructure development, economic stability, and technological advancements will play a crucial role in shaping the precision casting market in Latin America in the future. Despite a smaller market share, the region presents opportunities for both domestic and international precision casting manufacturers.

Company Profiles:

Prominent participants within the worldwide Precision Casting sector significantly contribute to fostering innovation, progressing manufacturing methodologies, and broadening market penetration. Leveraging their substantial knowledge and commitments to research and development, they endeavor to provide top-tier precision cast items to satisfy the increasing global consumer needs.

Prominent companies in the Precision Casting Industry consist of Rajesh Exports Limited, Alcoa Corporation, Precision Castparts Corporation, Amcol Metalcasting, Consolidated Precision Products Corp., Dongying Giayoung Precision Metal Co. Ltd., Hitachi Metals Ltd., Signicast LLC, Zollern GmbH & Co. KG, and Doncasters Group Limited.

COVID-19 Impact and Market Status:

The worldwide precision casting industry has experienced notable effects due to the Covid-19 outbreak, resulting in supply chain disturbances and reduced demand for precision castings in multiple sectors.

The precision casting market has been substantially influenced by the global effects of the COVID-19 pandemic. The enforced lockdowns and travel restrictions worldwide, aimed at curbing the virus's spread, disrupted supply chains and manufacturing processes, resulting in reduced demand for precision casting products in diverse sectors. Notably, the automotive industry, a primary user of precision castings, faced a substantial decline in sales as consumer behavior shifted towards postponing or cancelling vehicle purchases. Similarly, the aerospace sector, another key consumer of precision castings, experienced a downturn due to decreased air travel and the temporary halting of aircraft production. Nonetheless, amidst these challenges, the healthcare industry's demand for precision castings employed in medical equipment saw an increase. With the gradual easing of restrictions and resumption of economic operations in different countries, the precision casting market is forecasted to recover gradually. The long-term impact of the pandemic on the market's trajectory will hinge on various aspects such as the speed of economic revival, the rate of technological progress, and companies' ability to adjust to the new business environment. While the COVID-19 pandemic has detrimentally affected the precision casting market, prospects for recovery appear optimistic as industries adapt and recover within this evolving landscape.

Latest Trends and Innovation:

- In January 2021, Arconic announced the acquisition of Rio Tinto's Tital precision casting business, expanding its capabilities in aerospace and industrial manufacturing.

- In March 2021, Doncasters Group Ltd, a leading manufacturer of high-precision alloy components, announced its completion of the sale of its UK precision casting division to Westley Group, enabling Doncasters to focus on other core manufacturing areas.

- In May 2021, Precision Castparts Corp (PCC) introduced its new Precision Castparts Application Development Center, dedicated to advancing 3D printing technologies for precision casting applications in the aerospace and defense industries.

- In July 2021, Linamar Corporation, a diversified manufacturing company, acquired FerrouSouth Inc., a precision casting and machining company, to strengthen its casting capabilities in the automotive sector.

- In September 2021, ME Elecmetal, a leading manufacturer of cast steel grinding media and mill liners, announced the acquisition of Pacific Alloy Casting Co., enhancing its precision casting capabilities in the mining and mineral processing industries.

Significant Growth Factors:

The Precision Casting Market is on the brink of substantial expansion, propelled by a rising need from sectors such as aerospace, automotive, and healthcare.

The precision casting industry is poised for significant expansion in the near future due to a variety of compelling factors. One key driver is the increasing demand for precision castings across sectors such as automotive, aerospace, and energy. With their exceptional dimensional precision, intricate shaping capabilities, and superior surface quality, precision castings are highly sought after for critical applications within these industries. Moreover, the ongoing investments in infrastructure development and industrial growth in emerging markets are expected to further propel the market forward. These countries are experiencing a surge in construction and manufacturing endeavors, resulting in a ened need for precision castings. Additionally, technological advancements, including the integration of cutting-edge tools like 3D printing and simulation software, have transformed the precision casting landscape by allowing manufacturers to create intricate components with increased efficiency and precision. Furthermore, the industry is witnessing a growing emphasis on sustainability and the demand for lightweight components in sectors such as automotive and aerospace. This trend has led to an increased adoption of precision castings due to their ability to minimize material waste and energy consumption when compared to traditional manufacturing techniques. The market's growth is also being bolstered by the expanding shift towards electric vehicles, where precision castings play a pivotal role in enhancing vehicle performance through lightweighting strategies. Collectively, these factors paint a promising picture for the future growth trajectory of the precision casting industry.

Restraining Factors:

The Precision Casting industry faces limitations due to the substantial capital investment needed for establishing essential infrastructure and the scarcity of proficient workforce in the sector.

The precision casting sector, while seeing notable expansion on a global scale, faces various impediments. An essential obstacle is the significant expenses associated with the precision casting process, encompassing equipment, skilled labor, and raw materials. The intricate nature of precision casting necessitates specialized knowledge and skills, resulting in a scarcity of capable professionals, further hindering market progress. Furthermore, precision casting is a time-intensive procedure involving multiple stages and meticulous attention to detail, leading to extended production cycles and reduced output efficiency. Environmental concerns also confront the precision casting industry due to the utilization of certain materials like silica-based refractories, which could pose health risks and disrupt ecological equilibrium. Moreover, complying with stringent regulations and standards set by governmental bodies adds to the challenges for manufacturers, increasing operational costs and burdens. Despite these obstacles, the precision casting field presents promising prospects owing to its capacity to fabricate intricate forms and high-quality components with exceptional precision. The escalating demand for precision parts in sectors such as aerospace, automotive, and healthcare is poised to propel market expansion in the forthcoming years. By leveraging continuous technological progress and investments in research and development, the industry can address these challenges and maintain favorable growth in the foreseeable future.

Key Segmentation:

Offering Overview

• Equipment

• Components

• Service

Application Overview

• Automotive and Transportation

• Aerospace and Defense

• Oil and Gas

• Industrial Equipment

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America