Nitrobenzene Market Analysis and Insights:

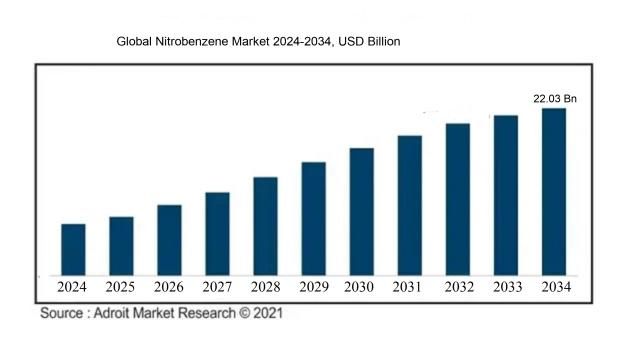

The worldwide nitrobenzene market is projected to grow at a compound annual growth rate (CAGR) of 6.09% from 2024 to 2034, from an estimated USD 13.15 billion in 2024 to around USD 22.03 billion by 2034.

The Nitrobenzene market is influenced by several significant elements, chiefly its vital function as a precursor in the synthesis of aniline, which is crucial for producing dyes, rubber additives, and pharmaceutical products. The rising need for these end products, especially in sectors such as textiles and automotive, amplifies the demand for nitrobenzene. Furthermore, the rapid industrialization and urban expansion in developing regions notably enhance market growth, as they increase the necessity for various chemicals and materials that incorporate nitrobenzene. Additionally, the landscape of the market is being molded by environmental regulations and safety issues, motivating manufacturers to implement more efficient production methods and explore eco-friendly alternatives. The volatility in raw material costs and potential supply chain interruptions also pose challenges to production and pricing strategies, further complicating the market environment. Together, these combined factors play a crucial role in determining the future direction of the Nitrobenzene market.

Nitrobenzene Market Definition

Nitrobenzene is a chemical compound represented by the formula C6H5NO2. It consists of a benzene ring that is attached to a nitro functional group (-NO2). This compound serves mainly as a key starting material in the production of aniline and various other aromatic substances.

Nitrobenzene is an important chemical in the industrial sector, chiefly recognized for its function as an intermediate in the creation of diverse chemical products. It is instrumental in the production of aniline, which is necessary for the manufacturing of dyes, chemicals used in rubber processing, and pharmaceuticals. Additionally, nitrobenzene acts as a solvent in a wide range of organic reactions and finds applications in the development of pesticides and explosives. Its distinct characteristics, such as being an effective solvent for polar substances, elevate its significance in both scientific research and industrial processes. As a precursor for synthesizing aromatic compounds, nitrobenzene is essential for advanced chemical manufacturing.

Nitrobenzene Market Segmental Analysis:

Insights On Application

Aniline Production

Aniline production is expected to dominate the Global Nitrobenzene Market due to its extensive use in the manufacture of various chemicals, including dyes, pharmaceuticals, and polymers. Aniline is primarily obtained through the reduction of nitrobenzene, making it a critical component in the production chain. As industries continue to demand synthetic textiles, advanced materials, and pharmaceutical products, the demand for aniline is projected to grow steadily. Furthermore, advancements in product formulations and increased investment in research and development are further propelling the growth of the aniline sector, affirming its position as the lead application for nitrobenzene.

Pesticide Additive

Pesticide additives represent a significant application for nitrobenzene, as they enhance the effectiveness and stability of various formulations. With the growing need for agricultural productivity to meet global food demands, this sector is experiencing a solid uptick in market interest. Increased awareness of crop protection measures and regulatory support for effective agricultural chemicals are contributing to the growth in pesticide additives, although competition from alternative solutions may temper rapid expansion relative to aniline production.

Synthetic Rubber Manufacturing

In the synthetic rubber manufacturing arena, nitrobenzene serves as an essential feedstock in the production of various rubber products. Its utilization is linked closely to the automotive and consumer goods industries, where demand for durable rubber materials continues. Ongoing innovations in synthetic rubber compounds, alongside a steady increase in the production of electric and hybrid vehicles, support growth potential. Nonetheless, the synthetic rubber sector faces challenges from advancements in bio-based alternatives, which may limit its market supremacy.

Paint Solvent

The paint solvent category leverages nitrobenzene for its solvent properties in industrial coating applications. While this application contributes to the overall consumption of nitrobenzene, it is challenged by environmental regulations and the rising popularity of eco-friendly alternatives. Furthermore, the volatility in construction and automotive industries directly influences demand. As paints evolve toward water-based solutions, the growth potential for paint solvents using nitrobenzene may diminish, making this application less dominant compared to aniline production.

Others

The “Others” category includes various niche applications where nitrobenzene is utilized, such as in the manufacturing of additives for plastics and certain pharmaceuticals. While these applications may hold relevance within specific industries, their overall consumption levels do not compare to leading applications like aniline production. The growth in this category is modest, often influenced by sector-specific developments or consumer trends, which cannot match the robust demand seen in more prominent applications.

Insights On End User

Pharmaceutical

The pharmaceutical industry is expected to dominate the Global Nitrobenzene Market due to its critical role as a precursor in the synthesis of various medicinal compounds and intermediates. Nitrobenzene is primarily utilized in the production of aniline, which is integral for manufacturing pharmaceuticals, dyes, and agrochemicals. The increasing demand for advanced and affordable healthcare solutions globally, bolstered by rising investments in drug development and research, is anticipated to prop up this sector's growth. Furthermore, innovations in drug formulation and delivery mechanisms, as well as a significant focus on R&D in pharmaceuticals, will likely strengthen the position of nitrobenzene within this industry.

Construction

The construction industry also plays a notable role in the demand for nitrobenzene, primarily due to its application in producing various construction chemicals. Nitrobenzene is utilized in making adhesives, sealants, and agglomerates, which are essential for construction projects. As urbanization continues to rise and infrastructure development expands worldwide, the construction sector's need for durable and high-performance materials will fuel the demand for nitrobenzene applications. Additionally, increasing investments in residential and commercial construction contribute to its growing utilization in this field.

Agriculture

In the agricultural sector, nitrobenzene’s importance lies in its application in manufacturing pesticides and herbicides. As global food demand increases with the world's growing population, the need for efficient crop protection products is paramount. Nitrobenzene serves as a crucial intermediary in the production of agrochemicals, thus influencing agricultural productivity. The rise in precision farming and integrated pest management techniques is expected to create a favorable outlook for nitrobenzene usage in the agricultural industry, driven by the need to enhance yield and reduce crop losses.

Automotive

The automotive industry is another significant area of nitrobenzene use, primarily due to its role in producing various components and materials. Nitrobenzene is involved in manufacturing synthetic rubber, plastics, and diverse chemicals necessary for vehicle production and maintenance. With the continuous advancement in transportation technology and increasing vehicle production rates globally, the automotive sector represents a consistent demand for nitrobenzene. Additionally, the growing emphasis on vehicle safety and automotive parts durability is likely to enhance the role of nitrobenzene within this industry.

Others

Various other industries also utilize nitrobenzene, which includes sectors like textiles and electronics. In textile manufacturing, nitrobenzene is part of the dyeing and finishing processes. The electronics industry uses nitrobenzene for producing specialty chemicals and materials essential in circuit board manufacturing. Although the demand from these sectors is substantial, it remains comparatively smaller than the primary industries mentioned previously. Nevertheless, the growth of niche applications in these diverse fields assures a continuous presence of nitrobenzene, contributing to its overall market demand.

Global Nitrobenzene Market Regional Insights:

Asia Pacific

The Asia Pacific region is expected to dominate the Global Nitrobenzene market due to its rapid industrialization and growing demand for agrochemicals, dyes, and pharmaceuticals. Countries such as China, India, and Japan are major contributors to this expansion, with increasing production capacity and significant investments in chemical manufacturing. The surge in automotive production and electronics manufacturing further drives nitrobenzene consumption in this region, as it is utilized in the manufacture of various intermediate chemicals. Additionally, the region benefits from a large population and increasing consumer activities, contributing to the ongoing demand for these applications in Asia Pacific's burgeoning economies.

North America

In North America, the market for nitrobenzene relies heavily on well-established industries, including automotive and pharmaceuticals. The United States and Canada maintain significant production capabilities, but growth is tempered by stringent regulations regarding chemical safety and environmental impact. Despite challenges, innovation in the manufacturing processes can potentially boost demand in this region, particularly in high-value applications.

Latin America

Latin America exhibits moderate growth potential in the nitrobenzene market, primarily driven by agricultural applications. Countries like Brazil and Argentina invest considerably in agrochemical products, creating opportunities for nitrobenzene manufacturers. However, economic instability and insufficient infrastructure can hinder market growth. Efforts to enhance agricultural productivity, coupled with increased global demand for food, could result in higher nitrobenzene consumption in the long term.

Europe

Europe shows a steady, regulated market for nitrobenzene, with a strong focus on sustainability and eco-friendly practices. The region's stringent environmental policies encourage the consumption of nitrobenzene in specialized industries, particularly in high-value chemical production. Nevertheless, the competition from alternative materials and chemical substitutes remains a challenge to substantial growth. The innovation landscape in Europe could potentially lead to new applications for nitrobenzene.

Middle East & Africa

In the Middle East and Africa, the nitrobenzene market is relatively marginal compared to other regions. The focus in this region predominantly lies in oil and gas, which can divert investment from chemical production. However, emerging markets and increasing industrial activities, especially in the Middle East, could provide some opportunities for growth. Challenges such as political instability and infrastructural limitations may impede rapid adoption of nitrobenzene in these markets.

Nitrobenzene Competitive Landscape:

Leading entities in the worldwide nitrobenzene sector, including BASF, Huntsman, and Zhejiang Jianye Chemical, propel the market forward through innovations in manufacturing techniques and an expanded range of products tailored to various applications. Their collaborative ventures and financial commitments improve supply chain efficiency and broaden their market presence, stimulating advancements in industries such as agriculture, pharmaceuticals, and chemicals.

The primary competitors in the nitrobenzene sector encompass BASF SE, Eastman Chemical Company, Huntsman Corporation, Anbang Chemical Co., Ltd., CABB Group, SUMITOMO Chemical Co., Ltd., Ningbo Jiangning Chemical Co., Ltd., Zhejiang Jianye Chemical Co., Ltd., and Yancheng Qianhong Chemical Co., Ltd. Furthermore, other notable entities include Jiangshan Chemical Co., Ltd., Shandong Tiancheng Biological Pharmaceutical Co., Ltd., and Hubei Greenhome Holdings Co., Ltd. These firms play a crucial role in the manufacturing and distribution of nitrobenzene, significantly influencing the market's overall landscape.

Global Nitrobenzene COVID-19 Impact and Market Status:

The Covid-19 pandemic had a profound effect on the worldwide nitrobenzene market, leading to a reduction in demand from essential sectors such as automotive and chemicals, alongside disruptions to supply chains and manufacturing processes.

The COVID-19 pandemic had a profound effect on the nitrobenzene market, largely due to interruptions in supply chains and a decrease in industrial output. Many manufacturing facilities, especially within the automotive and chemical industries, were either shut down or functioning at diminished capacity, resulting in a decline in the need for nitrobenzene—a vital precursor in the manufacture of aniline and various other chemicals. Additionally, limitations on transportation and the availability of raw materials further complicated production efforts. Nevertheless, certain sectors, including pharmaceuticals and agrochemicals, demonstrated resilience and even experienced growth, as their demand for nitrobenzene persisted for diverse uses, such as creating active pharmaceutical ingredients. In the aftermath of the pandemic, strategies for recovery are concentrating on restoring full production capabilities and addressing vulnerabilities in supply chains. Although the market experienced temporary declines during the most critical phases of the pandemic, a gradual recovery is anticipated as global economic activities stabilize, which should lead to an increase in demand for nitrobenzene derivatives in conjunction with the rebound and expansion of various industries.

Latest Trends and Innovation in The Global Nitrobenzene Market:

- In June 2022, Lanxess completed the acquisition of the specialty chemicals business of the German company, Sojitz Corporation, which included their production of Nitrobenzene, aimed at strengthening Lanxess's position in specialty chemicals.

- In September 2022, BASF announced the commissioning of a new Nitrobenzene production facility in China, designed to enhance their capacity in key markets for aniline production.

- In April 2023, Koppers Inc. expanded its operations by acquiring a nitroaromatics facility from a regional competitor, enhancing their product offerings in the Nitrobenzene and increasing production capabilities.

- In July 2023, Dow Chemical launched a new innovative process technology for Nitrobenzene synthesis, aimed at improving yield and reducing environmental impact, demonstrating Dow's commitment to sustainability in chemical production.

- In August 2023, Mitsubishi Gas Chemical Company expanded its Nitrobenzene production line in Japan, responding to increasing demand for specialty chemicals in various industrial applications.

- In September 2023, a merger was announced between INEOS and a leading Asian chemical firm, planning to establish a joint venture focused on the production of Nitrobenzene and its derivatives to capitalize on the growing market in Asia.

Nitrobenzene Market Growth Factors:

The expansion of the nitrobenzene market is largely fueled by the rising need for aniline and a range of chemicals employed in the automotive and textile sectors.

The Nitrobenzene sector is set to experience substantial growth, driven by several pivotal influences. Primarily, the surging requirement for aniline, a major derivative of nitrobenzene utilized in the manufacture of dyes, pharmaceuticals, and agrochemicals, is a key driver of market growth. The trends of urbanization and industrialization in developing nations are leading to increased investments in the chemical industry, consequently boosting nitrobenzene usage. Furthermore, the escalating automotive and aerospace sectors are ening the demand for synthetic rubber and plastics sourced from nitrobenzenes, which enhances their market viability. Stricter environmental regulations are encouraging the implementation of sustainable practices, promoting innovations in nitrobenzene production techniques, and paving the way for a more eco-friendly market landscape. The emergence of specialty chemicals, particularly within the Asia-Pacific region, is opening up new application avenues, broadening the potential customer base for nitrobenzene derivatives. Additionally, significant improvements in manufacturing processes that lower production costs and enhance yield are also favorable for market expansion. Ultimately, the combination of increasing industrial activities and shifting consumer preferences in emerging markets positions the Nitrobenzene sector for strong growth in the near future.

Nitrobenzene Market Restaining Factors:

Major limitations in the Nitrobenzene market stem from rigorous environmental regulations and safety issues associated with its hazardous nature.

The nitrobenzene market encounters various challenges that may hinder its expansion. Notable among these are the rigorous regulatory standards related to the manufacture and application of nitrobenzene, owing to its hazardous characteristics, which raise serious environmental and health issues. Compliance with these regulations often results in higher operational costs and necessitates sophisticated technologies to manage emissions, putting pressure on producers. Furthermore, the fluctuation in raw material prices, especially that of benzene, creates significant obstacles, as it can lead to varying production expenses and impact profit margins. The market's dependence on sectors like automotive and chemicals, which experience cyclical economic shifts, can cause instability in demand. Additionally, the presence of alternative products, including aniline and other safer compounds, can further constrict nitrobenzene's market presence. Concerns regarding safety and proper handling also deter investment in some areas. Nevertheless, innovations in production techniques and a growing range of applications in the pharmaceutical and agrochemical industries provide avenues for growth. Emphasizing sustainable practices and technological advancements may assist in alleviating some of these challenges, potentially fostering a more resilient market landscape in the coming years.

Key Segments of the Nitrobenzene Market

By Application

- Aniline Production

- Pesticide Additive

- Synthetic Rubber Manufacturing

- Paint Solvent

- Others

By End User

- Construction

- Agriculture

- Pharmaceutical

- Automotive

- Others

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America