Mobile Crushers And Screeners Market Analysis and Insights:

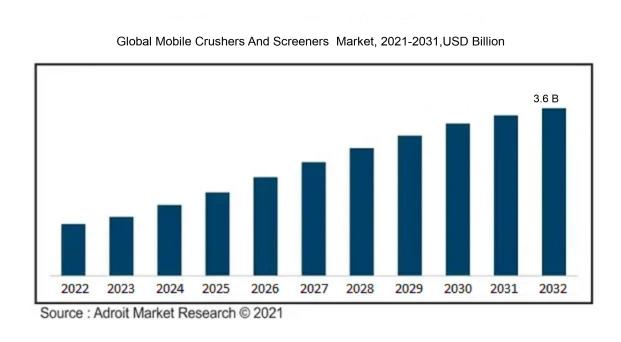

In 2023, the size of the worldwide Mobile Crushers And Screeners market was US$ 2.9 billion. Adroit Market Research projects that the market will increase at a compound annual growth rate (CAGR) of 4.3% from 2024 to 2032, reaching US$ 3.6 billion.

The market for Mobile Crushers and Screeners is chiefly propelled by ened mining operations and advancements in infrastructure, alongside a growing need for recycled materials. The global emphasis on sustainable practices incentivizes construction firms to incorporate recycled aggregates, thereby increasing the utilization of mobile crushing and screening machinery. Innovations in technology, including automation and improvements in energy efficiency within mobile equipment, further drive market expansion as operators look for economical and eco-friendly solutions. Additionally, the rise of urbanization and industrial growth in developing countries amplifies the demand for these flexible machines. Supportive government regulations that advocate for infrastructure initiatives also enhance market prospects. With industries focusing on versatility and minimizing operating expenses, mobile crushers and screeners have become vital assets for material handling and processing across diverse construction and mining environments, affirming their significance in the present and forthcoming market dynamics.

Mobile Crushers And Screeners Market Definition

Mobile crushers and screeners are versatile, portable equipment designed for on-site material crushing and screening. These machines enhance the efficiency of material handling in sectors such as construction, mining, and recycling by minimizing transportation requirements.

Mobile crushers and screeners are integral to the mining, construction, and recycling sectors, significantly enhancing material processing efficiency. By breaking down substantial quantities of rock and waste into smaller, more manageable forms, these machines boost productivity while also cutting transportation expenses. Their remarkable versatility permits operations directly at the site, minimizing the necessity for extra machinery and extensive preparatory work. Furthermore, these machines support sustainability initiatives by facilitating material recycling, which in turn decreases landfill waste. In summary, mobile crushers and screeners are vital for maximizing resource efficiency and elevating operational performance across diverse industrial fields.

Mobile Crushers And Screeners Market Segmental Analysis:

Insights On Product

Mobile Crushers

Mobile crushers are expected to dominate the Global Mobile Crushers and Screeners Market due to their versatility, adaptability, and increasing demand in construction and mining sectors. These mobile units allow for on-site processing of materials, which significantly reduces transportation costs and time. As infrastructure development accelerates in emerging economies, the need for efficient and impactful crushing solutions rises, propelling the demand for mobile crushers over stationary alternatives. Their capability to function in various environments, combined with advancements in technology enhancing their performance and productivity, positions mobile crushers as the most sought-after solution in the market.

Jaw Crushers

Jaw crushers remain a critical player in the crushing equipment market due to their robustness and the capability to handle large, tough materials effectively. They are largely utilized in primary crushing processes and are favored in industries such as mining and recycling. Their simplicity in design and ease of maintenance contribute to their widespread acceptance. However, as the market continues to evolve with high-demand applications and competition, jaw crushers are likely to remain relevant but will occupy a supportive role alongside more versatile options like mobile crushers.

Cone Crushers

Cone crushers offer exceptional performance in secondary and tertiary crushing applications, thanks to their ability to crush materials at a high throughput rate while producing a uniform product size. Their efficiency in handling materials such as granite, basalt, and other minerals makes them a staple in various industries. While they hold significant importance, particularly in aggregate production and mining, the growing inclination towards mobile solutions limits their standalone market share, positioning them prominently but still after mobile crushers in the overall market hierarchy.

Impact Crushers

Impact crushers are renowned for their capability to produce high-quality aggregates with excellent shape and consistency, making them particularly favored in construction tasks. They excel in operations where softer materials need to be reduced in size efficiently. However, the fixed nature of many impact crusher models can be a limitation compared to the flexibility that mobile units provide. As a result of their specialized use, while they are integral to specific applications, they are anticipated to take a backseat to mobile crushers that cater to a broader range of crushing requirements.

Mobile Screeners

Mobile screeners serve a vital role in ensuring the quality and segregation of materials after the crushing process. Their importance has grown with the increasing focus on recycling and material recovery, providing an efficient solution for sorting aggregates on site. However, while valuable, mobile screeners typically have a more limited market presence compared to mobile crushers, as they perform a supplementary role in the total material processing chain, thus securing their position as secondary players in the overall mobile equipment landscape.

Vibrating Screens

Vibrating screens play a critical role in many industries by providing a reliable method for separating and classifying materials based on size. They enhance the quality of processed material and are essential for both crushers and screeners. Nevertheless, their market visibility often intertwines with product systems that include crushers, which means they don't tend to dominate individually. Their function is crucial, but they generally support other machinery rather than taking a leading market position.

Trommel Screens

Trommel screens are particularly effective for materials screening with a focus on recycling and composting industries. They possess a unique mechanism that allows for efficient materials separation, especially for bulk materials. However, due to their specialized application scope, trommel screens do not command a large market share. Their relevance is more niche-based, making them important but not leading players in the overall mobile screening landscape.

Scalpers

Scalpers are utilized primarily for pre-screening applications, providing vital support for crushers by removing fines before the crushing process. Their specific application is crucial for optimizing the performance of primary crushers and enhancing overall productivity. However, due to their focused function, scalpers usually do not achieve significant market penetration compared to mobile or primary crushing equipment. They play an important role yet remain in the shadows of more versatile mobile machinery.

High-Frequency Screens

High-frequency screens are known for their capability to process high capacities with very fine separations. They enhance the efficiency of the screening process, providing a distinct edge in mineral processing and aggregate production. However, their specialized applications often confine them to niche roles within broader material processing systems. As such, their market share remains relatively limited when compared to mobile crushers and other more prevalent crushing solutions.

Others

The "Others" category encapsulates a variety of specialized crushing and screening equipment that might cater to niche markets or specific materials. While these machines can be important for very specialized applications, they generally do not see the same widespread use or demand as the main types of crushers and screeners, such as mobile crushers. Their market potential largely depends on unique circumstances or particular industry trends. Hence, they are expected to maintain a smaller market share in comparison to the primary machinery dominating the sector.

Insights On Operation

Tracked

The tracked category of mobile crushers and screeners is expected to dominate the global market due to its superior mobility and versatility in various terrains. These machines are designed for heavy-duty work, making them ideal for construction sites, mining operations, and other demanding environments. Their ability to maneuver easily and handle multiple applications makes them favored by operators seeking efficiency and productivity. Additionally, tracked machines often come equipped with advanced technology features, including telematics and automation, which appeal to construction companies focusing on productivity optimization. Overall, the demand for reliable and efficient tracking solutions is driving the growth of this sector.

Wheeled

Wheeled mobile crushers and screeners, while gaining traction in specific scenarios, tend to operate best on smoother terrain and paved surfaces. Their fast mobility allows for quicker relocation between sites, making them suitable for projects where time efficiency is crucial. However, the operational limitations in rough or uneven terrains diminish their versatility compared to tracked machines. As a result, although the wheeled holds value in applications like urban construction and recycling, it struggles to compete with the dominance of tracked options in more challenging work environments.

Insights On Output Potential

200 tph - 500 tph

The 200 tph - 500 tph category is expected to dominate the Global Mobile Crushers and Screeners Market. This caters effectively to both medium and large-scale projects, making it highly appealing to construction companies, mining operations, and recycling enterprises. The growing demand for efficient and versatile machinery that can handle a wide range of materials at reasonable outputs drives this ’s popularity. Additionally, advancements in technology have led to innovations in equipment that enhance productivity, reduce operational costs, and improve sustainability in operations, bolstering the appeal of mobile crushers and screeners within this output bracket.

Below 200 tph

The Below 200 tph category holds a crucial position in the Global Mobile Crushers and Screeners Market although it is not the leading. Equipment in this range is ideal for smaller projects, local contractors, and various recycling initiatives. These machines generally offer easier mobility and lower operating costs, making them attractive for less extensive operations that require flexibility. Their design often allows for straightforward maintenance and portability, which can address needs in congested urban areas or remote sites where space and access are constraint factors.

Above 500 tph

The Above 500 tph category, while less dominant, serves a significant niche in the Global Mobile Crushers and Screeners Market focused on large-scale industrial operations. This high-output caters to major mining and construction projects requiring immense production capabilities. Though the machines are often capital-intensive and demand significant investment, their efficiency in processing large volumes of material provides an essential solution for clients aiming for productive and cost-effective operations. As global infrastructure projects expand, there remains steady interest in high-capacity mobile crushers and screeners, ensuring the viability of this despite its smaller overall market share.

Insights On Distribution Channel

Indirect Sales

Indirect sales are projected to dominate the Global Mobile Crushers and Screeners Market due to their extensive reach and enhanced distribution network. This approach allows manufacturers to leverage third-party distributors, dealers, and retailers, reaching a wider audience while minimizing operational costs. The growing complexity of mobile machinery and the need for technical advice and support in various applications necessitate a robust network of experienced distributors. Moreover, indirect sales channels often provide localized services, which can be pivotal in driving customer satisfaction. With the increasing demand for mobile equipment across construction, mining, and recycling sectors, indirect sales can efficiently cater to diverse market needs, leading to their dominance.

Direct Sales

Direct sales involve manufacturers selling products directly to end-users without intermediaries. This method offers greater control over the sales process, pricing, and customer relationships. However, it requires substantial investment in logistics, marketing, and sales forces, making it less scalable than indirect sales. In niche markets where specialized equipment is required, direct sales may be beneficial, as companies can offer expert advice and tailored solutions. Nevertheless, the limitations in reaching a vast customer base often hinder the growth potential of direct sales in the broader Mobile Crushers and Screeners Market.

Insights On End User

Construction

The construction sector is anticipated to dominate the Global Mobile Crushers and Screeners market due to the increasing infrastructural development globally. Urbanization trends lead to ened demand for construction activities, resulting in a consistent need for efficient equipment like mobile crushers and screeners. These machines facilitate the processing of materials for new buildings, roads, and other infrastructures. Government initiatives to enhance infrastructure development, especially in emerging economies, further drive the demand within this sector. The ongoing rise in disposable income and government spending fosters growth, ensuring that construction remains the leading end-user in the mobile crushers and screeners market.

Mining

The mining industry is another significant user of mobile crushers and screeners. This sector requires efficient ways to break down and process minerals and other resources extracted from the earth. As mining activities expand across various regions to meet global resource demands, the need for mobile machinery that can manage and process materials on-site increases. Technological advancements in crushers and screens enhance productivity and efficiency, making them indispensable in mining operations. The sustained demand for precious metals, coal, and minerals contributes significantly to the growth of this category.

Material Recycling

Material recycling plays an important role in the mobile crushers and screeners market as the need for sustainable practices continues to rise. Companies focused on recycling operations increasingly utilize mobile equipment to sort and process materials like concrete, asphalt, and other construction waste. This trend not only reduces landfill waste but also contributes to a circular economy, where materials are reused. With growing awareness of environmental issues and regulations promoting recycling, this sector is likely to see steady growth, necessitating investment in mobile machinery.

Others

The 'Others' category includes diverse applications outside construction, mining, and material recycling, such as waste management and environmental restoration. While this does not currently dominate, it presents unique opportunities for growth due to technological innovations and increasing regulations for waste disposal and management. As industries evolve, there will likely be more investment in specialized mobile crushers and screeners tailored for niche applications. The gradual awareness of the importance of environmental sustainability drives interest in this category, suggesting potential future growth irrespective of its current standing in the market.

Global Mobile Crushers And Screeners Market Regional Insights:

Asia Pacific

Asia Pacific is expected to dominate the Global Mobile Crushers And Screeners market due to rapid industrialization and urbanization in countries like China and India. The region is witnessing significant investments in mining, construction, and infrastructure development, which are key drivers for demand in mobile crushing and screening equipment. Additionally, the increasing need for efficient waste processing and recycling solutions is propelling market growth. Local manufacturers are also adapting to market needs by innovating and offering cost-effective solutions, thereby enhancing their competitiveness. By 2023, the Asia Pacific region is positioned to capture a significant share of the market, driven by both revenue growth and volume expansion.

North America

In North America, the mobile crushers and screeners market is projected to grow steadily due to the presence of well-established construction and mining sectors. The region is characterized by technological advancements and high demand for sophisticated equipment that improves operational efficiency. Key players in the market offer innovative solutions tailored to meet the evolving needs of businesses. Additionally, government regulations promoting sustainable practices create further opportunities for growth, as mobile crushing and screening equipment facilitates environmental compliance through efficient waste management processes.

Europe

Europe remains a prominent market for mobile crushers and screeners, driven by stringent environmental regulations and a strong emphasis on sustainability. The construction industry in Europe is recovering, which boosts the demand for new equipment. Countries like Germany and the UK are leading the charge, investing heavily in infrastructure projects that require efficient mobile crushing solutions. Additionally, the European market benefits from advanced technology adoption and a focus on reducing carbon footprints, creating a favorable environment for growth in mobile screening and crushing equipment.

Latin America

The mobile crushers and screeners market in Latin America is gradually expanding, supported by increased investments in mining and construction activities. The growing need for urban infrastructure and housing projects is fostering demand for mobile equipment. However, economic fluctuations and political instability in certain countries may pose challenges to market growth. Despite these hurdles, localized operators are tapping into the rising demand for sustainable practices, viewing mobile crushers and screeners as significant assets in waste management and resource optimization.

Middle East & Africa

In the Middle East and Africa, the mobile crushers and screeners market shows promising growth potential, primarily fueled by ongoing major construction projects and mining activities. The region’s rich mineral resources and the government's commitment to infrastructure development create valuable opportunities for mobile crushing suppliers. However, the market faces challenges, including fluctuating oil prices and regional instability, which can impact investment levels. Nevertheless, as the focus on sustainable development rises, the demand for mobile crushing and screening equipment is expected to increase, particularly in waste recycling and materials processing applications.

Mobile Crushers And Screeners Market Competitive Landscape:

Leading figures in the worldwide market for mobile crushers and screeners play a critical role in advancing cutting-edge equipment and technologies, focusing on improved operational performance and sustainability. Their contributions to market expansion include forming strategic alliances, diversifying product offerings, and allocating resources to research and development initiatives.

Prominent participants in the market for mobile crushers and screeners encompass Metso Outotec, Terex Corporation, Sandvik AB, Kleemann GmbH, Astec Industries, McCloskey International, Liebherr Group, Epiroc, RB Scott Company, Doppstadt, Eagle Crusher Company, Powerscreen, Finlay, Keestrack, and SBM Mineral Processing.

Global Mobile Crushers And Screeners COVID-19 Impact and Market Status:

The Covid-19 pandemic caused considerable upheaval in the Global Mobile Crushers and Screeners market, leading to postponed projects, disruptions in supply chains, and a decline in demand within the construction and mining industries.

The COVID-19 pandemic had a profound effect on the market for mobile crushers and screeners, intensifying pre-existing difficulties within the construction and mining sectors. Lockdowns, shortages of labor, and supply chain disruptions led to a decline in demand as numerous projects were either halted or delayed, causing a downturn in production and postponing the delivery of machinery. However, as economies began to reopen and infrastructure initiatives were revitalized, there was a notable rebound in the demand for mobile crushing and screening technology. This resurgence was also supported by an increasing emphasis on sustainable and efficient processing practices. Additionally, a surge in recycling efforts to reduce waste during the pandemic ened the interest in mobile equipment, which provides flexibility and adaptability across a range of uses. By 2023, signs of recovery were evident, fueled by innovations and technological advancements that improved equipment efficiency, along with a rise in global infrastructure investment. Ultimately, while the pandemic introduced immediate adversities, it also paved the way for new opportunities and evolution within the industry.

Latest Trends and Innovation in The Global Mobile Crushers And Screeners Market:

- In June 2023, Sandvik expanded its portfolio by acquiring Schenck Process Group’s mobile screening business, enhancing its product offerings and operational capabilities in the mobile crushing and screening sectors.

- In March 2023, Terex Corporation launched the new Terex Finlay 695+ Supertrak screen, introducing advanced technology for improved efficiency and operational performance in various applications.

- In July 2023, McCloskey International and other companies within the McCloskey group joined forces in a strategic partnership with Metso Outotec to leverage advanced quarrying and mobile crushing technologies.

- In January 2023, the partnership between KPI-JCI and Astec Mobile Screens led to the introduction of a new line of hybrid mobile crushers, emphasizing sustainability and energy efficiency.

- In September 2023, Powerscreen unveiled its latest mobile screening model, the Powerscreen Warrior 2200, designed to enhance versatility and productivity in material handling.

- In August 2023, Wirtgen Group introduced a new range of mobile jaw crushers, focused on higher throughput and reduced operational costs through innovative engineering solutions.

- In October 2022, SBM Mineral Processing strengthened its market presence by acquiring a local rival, enabling the company to expand its service network and product distribution in Europe.

- In September 2023, Eagle Crusher launched its first electric-powered mobile jaw crusher, marking a significant step towards eco-friendly solutions in the mobile crushing sector.

- In February 2023, Finlay announced a joint venture with another leading manufacturer, aimed at developing smarter mobile screening technologies tailored for urban construction projects.

- In March 2023, Rubble Master celebrated the successful integration of AI technology into its mobile crushing equipment, allowing for real-time data analysis and improved operational efficiencies.

Mobile Crushers And Screeners Market Growth Factors:

The expansion of the Mobile Crushers and Screeners sector is fueled by escalating urban development, ened construction initiatives, and a notable increase in global mining activities.

The market for mobile crushers and screeners is witnessing remarkable expansion, influenced by several crucial factors. A major driving force is the escalating demand for construction and demolition operations, which necessitate effective material processing machinery. The surge in infrastructure development, especially in developing nations, is amplifying the need for mobile crushing and screening technologies due to their inherent flexibility and cost-efficiency. Additionally, an increasing emphasis on recycling and waste management is encouraging industries to integrate mobile crushers for the efficient processing of recyclable materials.

Technological advancements significantly contribute to this growth, with innovations improving the effectiveness, portability, and user-friendliness of these machines, thereby attracting a wider user base across sectors like mining, quarrying, and construction. Furthermore, government initiatives aimed at fostering sustainable construction methods are also endorsing the use of mobile solutions for material generation that minimizes environmental repercussions. The rising trend of rental services for construction equipment further accelerates market development, as operators look for economical solutions without the burden of significant capital investments. In summary, the interplay of infrastructure expansion, technological innovation, and a commitment to sustainability is poised to propel the mobile crushers and screeners market in the years to come.

Mobile Crushers And Screeners Market Restaining Factors:

The mobile crushers and screeners market faces significant challenges due to strict environmental regulations and elevated operational expenses.

The market for mobile crushers and screeners encounters numerous factors that could impede its expansion. A significant challenge is the elevated costs associated with operation and maintenance of mobile machinery, which may discourage investment from small and medium-sized enterprises. Additionally, the imposition of strict environmental regulations, along with the necessity to adhere to noise and emission standards, creates obstacles, especially in urban settings where this equipment is frequently utilized. The volatility in the prices of essential raw materials, such as steel, can also affect production expenses, resulting in unpredictable pricing for consumers. Furthermore, the sector's dependence on construction and mining industries renders it susceptible to economic fluctuations, given the cyclical nature of these fields. Limited familiarity and access to cutting-edge technologies in developing markets may further constrain growth potential. Conversely, the rising demand for recycling and effective waste management solutions indicates a positive trend for the industry. As new technological innovations, such as electric and hybrid mobile crushers, are introduced, the market is set to experience growth, ultimately fostering greater sustainability and operational efficiency.

Key Segments of the Mobile Crushers And Screeners Market

By Product

- Mobile crushers

- Jaw crushers

- Cone crushers

- Impact crushers

- Others

- Mobile screeners

- Vibrating screens

- Trommel screens

- Scalpers

- High-frequency screens

By Operation

- Tracked

- Wheeled

By Output Potential

- Below 200 tph

- Above 500 tph

- 200 tph 500 tph

By Distribution Channel

- Direct sales

- Indirect sales

By End User

- Construction

- Mining

- Material recycling

- Others

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America