Market Analysis and Insights:

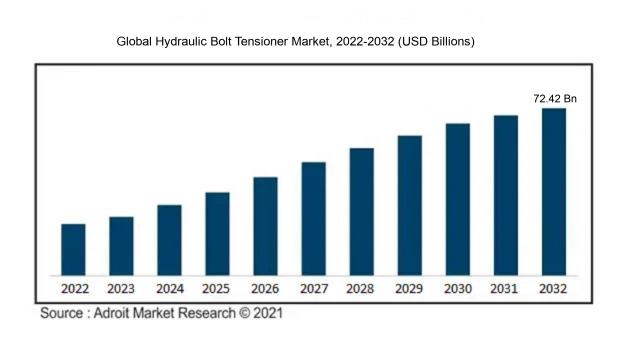

The market for global hydraulic bolt tensioner was estimated to be worth USD 42.84 billion in 2023, and from 2024 to 2032, it is anticipated to grow at a CAGR of 5.19%, with an expected value of USD 72.42 billion in 2032.

The market for hydraulic bolt tensioners experiences growth and demand due to several significant factors. The manufacturing and construction industries drive this growth by increasingly requiring hydraulic bolt tensioners to maintain precise and consistent bolt tension, crucial for ensuring the safety and reliability of structures and machinery. The emphasis on workplace safety and the efficient assembly and disassembly of equipment have further propelled the adoption of hydraulic bolt tensioners, offering enhanced control, accuracy, and reliability over traditional manual methods. The expansion of infrastructure development projects in emerging economies has also contributed to the surge in demand for hydraulic bolt tensioners, as the construction sector necessitates reliable and efficient fastening tools. Technological advancements, including the integration of intelligent and automated features in hydraulic bolt tensioners, have further boosted market growth by increasing efficiency and minimizing human error. In conclusion, the hydraulic bolt tensioner market is poised for significant expansion driven by a combination of these influential factors.

Hydraulic Bolt Tensioner Market Scope:

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2032 |

| Study Period | 2018-2032 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2032 | USD 72.42 billion |

| Growth Rate | CAGR of 5.19% during 2024-2032 |

| Segment Covered | By Type, By Application, By Sales Channel, By Region. |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Atlas Copco AB, SKF Group, ITH Bolting Technology, SPX FLOW Inc., Hydratight Ltd., Enerpac Tool Group, Boltight Ltd., Tentec Ltd., Tension Technology International, and Maxpro Technologies Inc. |

Market Definition

A hydraulic bolt tensioner is an apparatus employed to meticulously apply tension to bolts or studs, ensuring precise and consistent bolt loading. Its operation relies on hydraulic pressure to create a uniform and reliable force for tensioning.

The Hydraulic Bolt Tensioner stands as a pivotal instrument across various sectors by playing a crucial role in the establishment of appropriate tension levels and sealing of bolts. This apparatus is designed to administer a consistent and precise amount of tension to bolts, subsequently improving the distribution of bolt loads and guarding against leaks or failures caused by inadequate tightening. Its significance is particularly pronounced in industries like oil and gas, power generation, and construction, where the dependability and integrity of bolted connections are paramount. By facilitating accurate and regulated tension application, the Hydraulic Bolt Tensioner aids in upholding the structural soundness and operational security of machinery and equipment. Moreover, it minimizes the likelihood of thread damage, streamlines the installation procedure, and enhances the ease of maintenance and servicing. In essence, the Hydraulic Bolt Tensioner plays a significant role in enhancing the efficiency and durability of bolted connections in a multitude of industrial settings.

Key Market Segmentation:

Insights On Key Type

Topside Bolt Tensioner

The Topside Bolt Tensioner type is expected to dominate the Global Hydraulic Bolt Tensioner Market. This is due to several factors. Firstly, the increased demand for offshore oil and gas exploration and production activities has led to a higher usage of topside bolt tensioners. These tensioners are specifically designed for onshore and topside applications, making them suitable for a wide range of industries. Secondly, the advancements in technology have resulted in the development of more efficient topside bolt tensioners, which offer enhanced performance and reliability. Additionally, the stringent safety regulations imposed by various regulatory bodies have also contributed to the growing adoption of topside bolt tensioners, as they ensure proper bolt tensioning and prevent any potential hazards. Thus, the Topside Bolt Tensioner part is expected to dominate the Global Hydraulic Bolt Tensioner Market.

Sub Sea Bolt Tensioner

The Sub Sea Bolt Tensioner type is another significant sector of the Type of the Global Hydraulic Bolt Tensioner Market. This part is specifically designed for underwater or subsea applications, where the tensioners are utilized to ensure the proper tightening of bolts in deep-sea structures such as oil rigs and subsea pipelines. The increasing offshore oil and gas exploration and production activities have driven the demand for subsea bolt tensioners. Moreover, the continuous advancements in technology have resulted in the development of subsea bolt tensioners that can operate effectively in harsh underwater environments. Therefore, although the Sub Sea Bolt Tensioner part may not dominate the market like the Topside Bolt Tensioner part, it is still anticipated to hold a significant market share due to its specific applications and increasing demand.

Wind Power Bolt Tensioner

Although the Wind Power Bolt Tensioner type is expected to have steady growth in the Global Hydraulic Bolt Tensioner Market, it may not dominate the market like the Topside Bolt Tensioner type. This part caters to the wind power industry, where bolt tensioners are used to secure the components of wind turbines. The increasing focus on renewable energy sources and the expansion of wind power installations globally are driving the demand for wind power bolt tensioners. However, compared to the Topside Bolt Tensioner part, the market for wind power bolt tensioners is relatively niche and limited to the wind power industry. Therefore, while it may not dominate the overall market, it is expected to have a significant presence within its specific industry niche.

Insights On Key Application

Wind and Power Generation

The Wind and Power Generation is expected to dominate the Global Hydraulic Bolt Tensioner Market. With the increasing focus on renewable energy sources, particularly wind power generation, the demand for hydraulic bolt tensioners in this industry is projected to be the highest among the parts. Wind turbines require strong and reliable fastening solutions to withstand the high wind speeds and vibrations, making hydraulic bolt tensioners an essential component in the wind and power generation sector. The growth in wind farm installations worldwide and government initiatives promoting renewable energy will further drive the demand for hydraulic bolt tensioners in this part.

Oil and Gas Industry

The Oil and Gas Industry is another significant sector of the Global Hydraulic Bolt Tensioner Market. In this industry, hydraulic bolt tensioners are utilized in various applications such as wellhead flanges, pipeline connections, and pressure vessel joints. The continuous exploration and production activities in the oil and gas sector, coupled with the need for safe and reliable fastening solutions, drive the demand for hydraulic bolt tensioners. Although the wind and power generation part is expected to dominate the market, the oil and gas industry remains a key player due to its ongoing operations and infrastructure development.

Industrial

The Industrial category is an important sector of the Global Hydraulic Bolt Tensioner Market. The industrial sector includes various applications such as heavy machinery, construction equipment, and manufacturing plants, where hydraulic bolt tensioners are used for fastening large and heavy components. The industrial part is expected to witness steady growth as manufacturing processes and infrastructure development continue to expand globally. Although it may not dominate the market like the wind and power generation part, the industrial sector represents a significant portion of the demand for hydraulic bolt tensioners.

Others

The Others category encompasses various applications that do not fall under the specific categories of oil and gas industry, wind and power generation, or industrial sector. These applications could include niche industries, customized projects, or emerging sectors that require hydraulic bolt tensioners for their specific requirements. While the volume of demand in the Others part may not be as high as the dominant parts, it still contributes to the overall market. The growth in this part can be driven by factors such as innovative applications or emerging industries that may arise in the future.

Insights On Key Sales Channel

Indirect Channel

The Indirect Channel is expected to dominate the Global Hydraulic Bolt Tensioner Market. With the increasing demand for hydraulic bolt tensioners in various industries such as oil and gas, power generation, and construction, there has been a significant shift towards the use of the Indirect Channel for distribution. This can be attributed to the wide network of distributors, dealers, and retailers that operate in different regions, allowing for wider market coverage and accessibility to customers. Furthermore, the Indirect Channel offers the convenience of local support, after-sales service, and technical expertise, which are crucial factors driving its dominance in the market. Through collaborations and partnerships with distributors, hydraulic bolt tensioner manufacturers can effectively reach a larger customer base and strengthen their market presence.

Direct Channel

While the Indirect Channel is expected to dominate the Global Hydraulic Bolt Tensioner Market, the Direct Channel still plays a significant role in the industry. The Direct Channel refers to the direct sale of hydraulic bolt tensioners from the manufacturer to end-users, bypassing intermediaries such as distributors or retailers. This part appeals to certain customers who prefer direct communication and negotiation with manufacturers, as well as those looking for more customized solutions or bulk orders. Some manufacturers may also leverage the Direct Channel to establish their brand reputation and build stronger relationships with key customers. However, due to factors such as limited geographical reach and higher cost of marketing and distribution, the Direct Channel is expected to have a smaller market share compared to the Indirect Channel.

Insights on Regional Analysis:

Asia Pacific

Asia Pacific is expected to dominate the Global Hydraulic Bolt Tensioner market. The region is witnessing significant growth due to the rapid industrialization and infrastructure development in countries like China and India. These countries have a strong manufacturing base and a large number of ongoing construction projects, which are driving the demand for hydraulic bolt tensioners. Additionally, the expanding automotive and aerospace sectors in the region are also contributing to the market growth. Overall, with its booming industrial and manufacturing sectors, Asia Pacific is expected to dominate the global hydraulic bolt tensioner market.

North America

With its advanced industrial infrastructure and robust manufacturing sector, North America is expected to be a significant market for hydraulic bolt tensioners. The region is home to several established automotive, aerospace, and oil & gas industries, which are major end-users of hydraulic bolt tensioners. Furthermore, the increasing focus on equipment safety and maintenance in these industries is driving the demand for hydraulic bolt tensioners. The presence of key market players and ongoing technological advancements in the region further contribute to the growth potential of the North American hydraulic bolt tensioner market.

Europe

Europe is another region that holds considerable market potential for hydraulic bolt tensioners. The region has a well-developed manufacturing sector, particularly in sectors such as automotive, aerospace, and construction machinery. The stringent industrial safety standards in Europe also drive the demand for hydraulic bolt tensioners as a reliable and efficient means of ensuring proper fastening in critical applications. Additionally, the growing emphasis on environmental sustainability and energy-efficient solutions in Europe is expected to fuel the demand for hydraulic bolt tensioners in the region.

Latin America

Latin America is experiencing steady growth in the hydraulic bolt tensioner market. The region's expanding oil & gas industry, coupled with ongoing infrastructure development projects, is driving the demand for hydraulic bolt tensioners. Moreover, the growing automotive and manufacturing sectors in countries like Brazil and Mexico also contribute to the market growth. However, the market in Latin America is still relatively smaller compared to other regions, but it presents significant growth opportunities, particularly with the increasing focus on safety and reliability in various industries.

Middle East & Africa

The Middle East & Africa region is anticipated to witness moderate growth in the hydraulic bolt tensioner market. The region's oil & gas industry, along with the growing construction and infrastructure sectors, creates a demand for hydraulic bolt tensioners for various applications. However, the market in this region is relatively smaller compared to others, and the presence of alternative fastening solutions may impact the growth potential. Nonetheless, ongoing industrial development projects and increased focus on safety regulations in the Middle East & Africa are expected to drive the demand for hydraulic bolt tensioners in the region.

Company Profiles:

Key stakeholders in the global hydraulic bolt tensioner industry exert a substantial influence on fostering innovation and technological progress, thereby molding the competitive environment of the sector. Their provision of a diverse array of top-tier products and services caters to the varied requirements of a global customer base, ultimately fueling market expansion.

Prominent companies in the Hydraulic Bolt Tensioner Market encompass industry leaders such as Atlas Copco AB, SKF Group, ITH Bolting Technology, SPX FLOW Inc., Hydratight Ltd., Enerpac Tool Group, Boltight Ltd., Tentec Ltd., Tension Technology International, and Maxpro Technologies Inc. These esteemed organizations are recognized for their proficiency in producing top-tier hydraulic bolt tensioning systems and delivering comprehensive solutions tailored to diverse industrial needs. Leveraging cutting-edge technologies, diverse product offerings, and extensive global reach, these key stakeholders significantly contribute to propelling advancement and fostering innovation within the hydraulic bolt tensioner sector.

COVID-19 Impact and Market Status:

The worldwide market for hydraulic bolt tensioners has seen a slowdown in its growth trajectory, mainly attributed to the disruptive effects of the Covid-19 pandemic on diverse sectors and diminished construction undertakings.

The hydraulic bolt tensioner market has experienced significant disruption due to the global economic impacts of the COVID-19 pandemic. Government lockdowns and restrictions, instituted to curtail virus transmission, have disturbed supply chains and manufacturing operations, culminating in a decreased demand for hydraulic bolt tensioners. Key sectors like construction and automotive, primary consumers of these products, have suffered setbacks, including project delays and financial limitations. Moreover, lingering economic instability and weakened consumer purchasing power have further exacerbated the drop in market demand. Nevertheless, as countries progressively ease restrictions and revive economic operations, there are prospects for a revival in the market. Anticipated market recovery will be gradual, buoyed by increasing demand driven by infrastructure ventures and a resurgence in automotive manufacturing. Manufacturers are prioritizing product innovation and customization to align with evolving consumer requirements. Despite the adverse impacts of the pandemic on the hydraulic bolt tensioner market, there are glimpses of a turnaround and avenues for future expansion.

Latest Trends and Innovation:

- On March 9, 2021, SPX FLOW, a global leader in pump and system solutions, announced the launch of its new hydraulic bolt tensioner range, which includes both topside and subsea tensioning systems.

- In October 2020, ITH Bolting Technology, a leading provider of hydraulic bolt tensioning systems, announced the introduction of its new Generation X line of tensioners, offering enhanced safety and performance.

- In September 2020, Atlas Copco, a Swedish industrial company, acquired ITH Bolting Technology, expanding its portfolio of hydraulic bolting solutions and strengthening its position in the market.

- In May 2020, Enerpac, a global provider of hydraulic tools and solutions, introduced its new GT-Series hydraulic bolt tensioners, designed for accurate and repeatable tensioning.

- In January 2020, WREN Hydraulic Equipment, a leading manufacturer of hydraulic tools, launched its advanced hydraulic bolt tensioner series, offering increased productivity and efficiency.

Significant Growth Factors:

The expansion drivers of the Hydraulic Bolt Tensioner sector encompass rising requirements from the construction and manufacturing sectors, technological progress, and the necessity for precise and effective bolt fastening remedies.

The market for hydraulic bolt tensioners is projected to witness substantial growth due to various factors. Primarily, the growing need for effective and efficient bolting solutions in industries like oil and gas, energy, and manufacturing is propelling market growth. These sectors heavily rely on bolted joints for their operations, leading to the adoption of advanced tensioning tools such as hydraulic bolt tensioners to ensure precise and accurate tightening. Additionally, the increasing utilization of hydraulic bolt tensioners in the installation and maintenance of wind turbines is contributing to the market's expansion. The surge in renewable energy sources and the proliferation of wind farms worldwide are driving the demand for hydraulic bolt tensioners. Furthermore, the emphasis on enhancing safety in industrial activities is driving market growth. Hydraulic bolt tensioners enhance operator safety by reducing the likelihood of accidents during the tightening process.

Moreover, the incorporation of cutting-edge technologies like IoT and automation in hydraulic bolt tensioners is expected to further boost market growth. These technologies enable real-time monitoring and control of tensioning operations, ensuring optimal performance and preventing costly failures. In essence, the confluence of increased industrial requirements, the growth of the renewable energy sector, safety imperatives, and technological innovations are the primary growth catalysts for the hydraulic bolt tensioner market.

Restraining Factors:

A lack of widespread understanding and utilization of hydraulic bolt tensioners within specific sectors serves as a barrier to market growth.

The market for hydraulic bolt tensioners is on an upward trajectory fueled by growing demand across multiple sectors including oil and gas, power generation, and automotive. However, there are challenges that could impede its expansion. The significant cost of hydraulic bolt tensioners presents a hurdle for small and medium-sized enterprises operating within constrained budgets. Moreover, the intricate nature and specialized knowledge required for using these tensioners properly may discourage end-users from embracing the technology. Competition from manual or pneumatic bolt tensioners also emerges as a potential threat to the hydraulic bolt tensioner market.

Furthermore, lack of awareness regarding the advantages offered by hydraulic bolt tensioners among potential consumers could hinder market growth.

Despite these obstacles, the future of the hydraulic bolt tensioner market appears promising. An increasing focus on safety and the demand for effective and reliable bolt tightening solutions are poised to propel the adoption of hydraulic bolt tensioners. Furthermore, technological advancements and product innovations are anticipated to yield more cost-efficient solutions, expanding the accessibility of hydraulic bolt tensioners to a broader customer base. In essence, although there are barriers affecting the market, the overall outlook for hydraulic bolt tensioners remains positive.

Key Segments of the Hydraulic Bolt Tensioner Market

Type Overview

• Topside Bolt Tensioner

• Sub Sea Bolt Tensioner

• Wind Power Bolt Tensioner

Application Overview

• Oil and Gas Industry

• Wind and Power Generation

• Industrial

• Others

Sales Channel Overview

• Direct Channel

• Indirect Channel

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America