Honeycomb Core Materials Market Analysis and Insights:

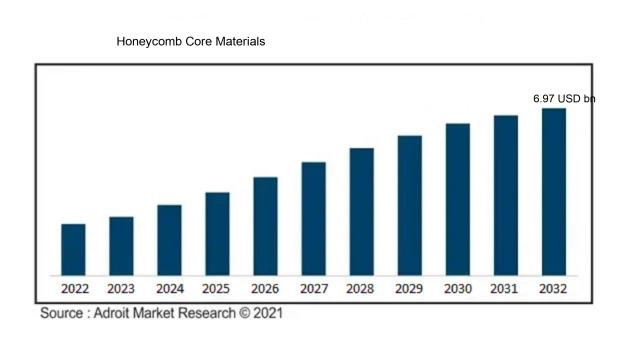

The market for Honeycomb Core Materials was estimated to be worth USD 3.25 billion in 2022, and from 2023 to 2032, it is anticipated to grow at a CAGR of 8.1%, with an expected value of USD 6.97 billion in 2032.

The market for Honeycomb Core Materials is predominantly fueled by innovations in lightweight structural technologies that boost the performance and efficiency across various fields, notably in aerospace, automotive, and construction. The escalating need for energy-efficient vehicles and aircraft, coupled with rigorous emission regulations, drives the increased utilization of honeycomb materials due to their exceptional strength-to-weight ratio. Additionally, the burgeoning renewable energy sector, particularly wind power, has ened the demand for advanced composite materials used in turbine blades. Technological progress, including the creation of honeycomb cores that are resistant to high temperatures and fire, expands their range of applications. Furthermore, growing consumer consciousness regarding sustainability and the preference for recyclable materials encourage market growth as manufacturers pursue environmentally friendly options. The global expansion of infrastructure initiatives also boosts the demand for honeycomb core materials in construction, highlighting their versatile nature and advantageous properties in reinforcing structural integrity.

Honeycomb Core Materials Market Definition

Honeycomb core materials consist of lightweight composite frameworks characterized by a hexagonal configuration, which offers exceptional strength-to-weight ratios. These materials find extensive application in industries such as aerospace, automotive, and construction due to their remarkable structural efficiency and resilience.

Honeycomb core materials are integral to numerous sectors, especially in aerospace, automotive, and construction, thanks to their remarkable strength-to-weight ratio and structural effectiveness. Comprising a lightweight core positioned between two outer layers, these materials deliver exceptional rigidity while keeping weight to a minimum. This unique feature improves fuel efficiency in both aircraft and vehicles, cuts down on material expenses, and supports sustainability efforts by reducing energy usage. Furthermore, honeycomb cores provide outstanding thermal insulation and soundproofing properties, making them ideal for diverse applications. Their adaptability and performance characteristics further enhance design and engineering developments, driving innovation in advanced products.

Honeycomb Core Materials Market Segmental Analysis:

Insights On Type

Aluminum

Aluminum is expected to dominate the Global Honeycomb Core Materials Market due to its unique combination of lightweight properties, strength, and resistance to corrosion. This versatility makes aluminum honeycomb cores particularly suitable for various industries, including aerospace, automotive, and construction. The trend towards lightweight materials in transportation and the demand for energy-efficient solutions are effectively driven by the inherent advantages of aluminum. Additionally, its recyclability aligns with increasing sustainability goals, making aluminum a focal point for manufacturers looking to optimize performance while minimizing environmental impact. Thus, the aluminum category stands out as the leader in this market.

Paper

Paper honeycomb materials are utilized primarily in packaging and lightweight construction applications. Their appeal lies in their biodegradability and eco-friendliness, aligning with the growing consumer demand for sustainable products. Despite offering lower structural strength compared to aluminum, paper honeycomb cores provide excellent cushioning and shock absorption qualities, making them suitable for protective packaging. The increasing emphasis on reducing carbon footprints and waste is likely to bolster the adoption of paper honeycomb products in various industries, particularly in e-commerce and food packaging sectors.

Nomex

Nomex is widely recognized in industries requiring high-temperature resistance and superior flame retardancy. This quality makes it an ideal choice for applications, particularly in aerospace, military, and automotive sectors. Although its cost is generally higher than that of paper or aluminum alternatives, Nomex provides unique advantages in terms of thermal stability and durability. As industries continue to prioritize safety and performance, demand for Nomex-based honeycomb materials is expected to grow, although they may not surpass aluminum in overall market share.

Thermoplastic

Thermoplastic honeycomb materials offer excellent durability, chemical resistance, and flexibility, making them suited for various applications, including automotive interiors and building materials. Their ability to be thermoformed allows for complex shapes and designs, which is a significant advantage in product development. Moreover, the recycling potential of thermoplastics aligns with sustainability initiatives in multiple sectors. While they hold a niche market share compared to aluminum and other materials, the demand for thermoplastic cores is gradually increasing as manufacturers look to incorporate innovative, lightweight solutions in their projects.

Others

The "Others" category includes various specialized materials such as fiberglass and composite honeycomb cores. These materials can be utilized in specific applications where conventional materials may not meet the performance requirements. For instance, fiberglass honeycomb cores often exhibit high strength-to-weight ratios and are used in specialized sectors like marine and industrial equipment. The growth in niche applications may lead to an increase in the market fragmentation, although these alternatives are expected to remain significantly overshadowed by the leading materials, particularly aluminum.

Insights On End User

Composites

The Composites category is projected to dominate the Global Honeycomb Core Materials Market due to its wide range of applications across various industries such as aerospace, automotive, and construction. The demand for lightweight yet strong materials is continually increasing as industries strive to improve fuel efficiency and reduce environmental impact. Composites, characterized by their optimal strength-to-weight ratio, have gained preference in the production of aircraft parts, automotive components, and architectural elements, making them crucial for innovative projects and sustainable development. As manufacturers increasingly focus on efficient and high-performance materials, the composite will maintain a strong foothold in the marketplace.

Non-Composites

Non-Composites materials, which traditionally include metals and plastics, are experiencing steady demand, albeit at a slower growth rate compared to composites. Their usage primarily arises in applications where cost-effectiveness is prioritized over weight considerations. Industries like construction may still rely on non-composite honeycomb structures due to their robustness and lower material costs. However, they face competition from composites that offer enhanced performance characteristics. As such, while non-composites hold a significant share, they may not secure dominance in the evolving market landscape driven by technological advancements and changing customer preferences.

Insights On Application

Aerospace & Defense

The Aerospace & Defense sector is projected to dominate the Global Honeycomb Core Materials Market due to the increasing demand for lightweight, high-strength materials that enhance fuel efficiency and performance in aircraft and defense systems. With advancements in aerospace design, the need for materials that can withstand high-stress environments while minimizing weight is crucial. Honeycomb core materials, characterized by their excellent strength-to-weight ratio, are becoming increasingly integral in the manufacturing of aircraft components and structural elements in military vehicles. This sector's continued growth, driven by technological advancements and increasing air travel, positions it as the leading application area for honeycomb core materials.

Packaging

The Packaging sector represents a significant application area for Honeycomb Core Materials. This industry is witnessing a growing trend toward sustainable and lightweight packaging solutions, which has led to increased usage of honeycomb materials. Their structural integrity and ability to reduce material consumption while providing excellent cushioning are key advantages that align well with the industry's shifts toward eco-friendliness and cost efficiency. The growing e-commerce market and the demand for protective, durable packaging solutions further enhance the appeal of honeycomb structures in this.

Construction & Infrastructure

The Construction & Infrastructure sector is gradually increasing its adoption of Honeycomb Core Materials due to their outstanding properties that enhance building efficiency and reduce weight in structural components. These materials offer improved insulation, sound resistance, and durability, making them particularly valuable in modern construction practices. As the infrastructure industry shifts toward innovative building techniques and sustainable practices, the role of honeycomb materials is likely to gain prominence, facilitating advancements in modular construction and enhancing overall structural performance.

Transportation

In the Transportation sector, honeycomb core materials are gaining traction because of the industry's constant need for lightweight and strong materials that improve fuel efficiency and performance. Used in various applications from automotive components to rail systems, these materials provide a great balance between weight savings and structural integrity. As regulations tighten regarding emissions and fuel consumption, manufacturers are increasingly turning to honeycomb solutions to meet these challenges. This demand for innovative materials that can enhance vehicle performance positions the transportation industry as a noteworthy area of application for honeycomb core materials.

Others

The 'Others' category encompasses diverse applications that may not fit neatly into the aforementioned s but still require the advantages offered by Honeycomb Core Materials. Industries such as marine, industrial equipment, and consumer goods are beginning to recognize the benefits these materials provide, including enhanced strength, reduced weight, and increased energy efficiency. As innovation continues across various fields, the flexibility and adaptability of honeycomb core materials allow them to serve emerging applications, suggesting a steady growth in this, albeit at a slower pace compared to more dominant sectors.

Global Honeycomb Core Materials Market Regional Insights:

Asia Pacific

The Asia Pacific region is expected to dominate the Global Honeycomb Core Materials market due to several compelling factors. The area has witnessed rapid industrial growth, particularly in the aerospace, automotive, and construction sectors, leading to an increased demand for lightweight and durable materials. Countries like China and India are significantly investing in infrastructure development and manufacturing capabilities, driving the adoption of honeycomb core materials. Additionally, the region benefits from an abundance of raw materials, cost-effective labor, and advanced technology, which collectively push production efficiencies. As manufacturers aim for sustainability, honeycomb core materials provide excellent options for energy efficiency, further solidifying Asia Pacific's leadership in this market.

North America

North America remains a notable contender in the Global Honeycomb Core Materials market, primarily led by the advanced aerospace and automotive industries. The strong emphasis on innovation and technological advancement in countries like the United States and Canada further bolsters its position. OEMs in this region increasingly adopt honeycomb core materials to enhance performance and reduce weight, aligning with environmental regulations. However, market growth may be tempered by economic fluctuations and trade discussions impacting material costs and supply chains.

Latin America

Latin America shows potential for growth within the Global Honeycomb Core Materials market, albeit at a slower pace compared to other regions. Countries such as Brazil and Mexico are investing in industrialization, particularly in construction and transportation. However, challenges including economic instability and limited investments in research and development may hinder the widespread adoption of honeycomb core materials. The demand can be driven by emerging industries, but it still remains a developing.

Europe

Europe presents a competitive landscape for the Global Honeycomb Core Materials market, driven by the region's commitment to sustainability and lightweight solutions in various sectors, notably aerospace and automotive. Countries like Germany, France, and the UK are focusing on advancements in material technology and eco-friendly practices. However, stringent regulations and high manufacturing costs may create barriers for smaller players. Collaboration among key industry players is essential for leveraging innovations and growth opportunities within this market.

Middle East & Africa

The Middle East & Africa region is currently in the nascent stage of the Global Honeycomb Core Materials market. While there is growing interest due to the rising construction and automotive sectors, the market remains limited by factors such as economic volatility, regulatory challenges, and less awareness about the benefits of honeycomb core materials. However, investment in infrastructure and increasing government support for sustainable materials can open opportunities for market growth in the future, although it remains secondary compared to other regions.

Honeycomb Core Materials Competitive Landscape:

Leading contributors in the Global Honeycomb Core Materials sector propel advancements and optimize manufacturing effectiveness by creating cutting-edge materials that improve structural integrity and minimize weight across diverse industries. Their strategic partnerships and commitments to research significantly influence market dynamics and address the changing demands of consumers.

Prominent entities in the Honeycomb Core Materials sector comprise Hexcel Corporation, Aramid Honeycomb, Pacific Panels, Gurit Holdings AG, Rock West Composites, The Gill Corporation, Kevlar Honeycomb, AIREX, Creaform, and Axiom Materials Inc. In addition, notable mentions include Airstreams, Expanded Polystyrene (EPS) Honeycomb, Plascore Inc., Core Materials Group, and Sanlitong Technologies. These firms are esteemed for their innovative contributions and leadership in manufacturing and supplying honeycomb core materials, which find applications in diverse fields such as aerospace, automotive, and beyond.

Global Honeycomb Core Materials COVID-19 Impact and Market Status:

The Covid-19 pandemic significantly impacted the Global Honeycomb Core Materials market, resulting in supply chain disruptions and a decrease in manufacturing capabilities. This situation caused production delays and a temporary drop in demand in multiple sectors.

The honeycomb core materials market experienced considerable disruptions due to the COVID-19 pandemic, primarily stemming from supply chain challenges and a reduction in demand from critical sectors like aerospace and automotive. Temporary shutdowns or scaled-back operations in manufacturing facilities led to production delays for these materials. Furthermore, a decline in air travel during the pandemic resulted in diminished airline operations, which negatively impacted the need for lightweight, high-strength core materials essential for aircraft construction. Nevertheless, as various industries began to recover in late 2020 and early 2021, the market began to demonstrate resilience. There was a growing interest in lightweight materials for electric vehicle applications and an emphasis on enhanced sustainability efforts. The pandemic also acted as a catalyst for advancements in manufacturing techniques and material development, suggesting potential growth as the economy revitalizes. While the initial repercussions were adverse, the long-term prospects for honeycomb core materials appear more encouraging as industries adapt to evolving market dynamics.

Latest Trends and Innovation in The Global Honeycomb Core Materials Market:

- In February 2021, Hexcel Corporation announced the acquisition of the French company, "Dufour Aerospace," aimed at expanding its capabilities in the aerospace sector by integrating advanced honeycomb core materials into future urban air mobility designs.

- In August 2021, Aramid Materials introduced its patented 3D honeycomb core technology, which significantly enhances the strength-to-weight ratio in composite materials used for aerospace applications.

- In September 2021, CoreFX Technologies, a leader in advanced core material solutions, launched its new line of eco-friendly honeycomb core materials derived from sustainable resources, targeting the growing demand for sustainable aerospace products.

- In July 2022, Alberta-based ThermoAdvanced Composites secured a major partnership with Boeing, focusing on developing innovative honeycomb structures that improve fuel efficiency in military aircraft.

- In March 2022, The Composite Panel Association (CPA) reported a significant increase in the use of aluminum honeycomb panels in automotive applications, driven by a joint initiative involving companies like Mitsubishi Chemical and DuPont.

- In April 2023, Bannering Innovations announced the completion of its state-of-the-art manufacturing facility dedicated to producing advanced honeycomb core materials, expanding its production capacity by 50%.

- In October 2023, BASF introduced a groundbreaking resin system specifically designed for the production of honeycomb core materials, enhancing the thermal stability and mechanical performance of the resulting composites.

Honeycomb Core Materials Market Growth Factors:

The Honeycomb Core Materials Market is experiencing growth driven by the rising need for lightweight and resilient materials across the aerospace, automotive, and construction sectors.

The Honeycomb Core Materials Market is witnessing considerable expansion driven by several critical factors. Primarily, there is an escalating need for lightweight yet robust materials across various sectors, including aerospace, automotive, and construction. Honeycomb configurations provide remarkable strength-to-weight ratios, which significantly improve fuel efficiency and overall performance. Furthermore, increasing regulatory requirements regarding energy consumption and emissions are encouraging manufacturers to transition to these innovative materials.

The surge in the renewable energy industry, especially in applications involving wind turbines, is also propelling market demand. Advances in manufacturing techniques and the emergence of new materials, such as thermoplastic and composite honeycomb cores, are further enhancing market growth through improved properties and sustainability. Additionally, the rising emphasis on environmentally friendly materials and efficient recycling aligns with the ened environmental awareness among consumers and businesses.

The COVID-19 pandemic has accelerated the shift towards digitalization and automation, prompting industries to pursue cost-effective and resilient materials, where honeycomb structures serve as an effective solution. In summary, the interplay of technological innovations, regulatory influences, and the market's pursuit of efficient materials positions the Honeycomb Core Materials Market for significant growth in the years ahead.

Honeycomb Core Materials Market Restaining Factors:

The Honeycomb Core Materials Market is hindered by elevated production expenses and a lack of understanding regarding its diverse applications across multiple sectors.

The Honeycomb Core Materials Market is influenced by several limiting factors that could impede its expansion. One major issue is the substantial production costs tied to the creation of advanced materials, which may discourage uptake, particularly among smaller businesses. Moreover, the specialized nature of honeycomb materials necessitates a considerable investment in research and development, which might dissuade new entrants into the market. Additional complexities arise from regulatory hurdles, especially those linked to environmental issues and recycling standards.

A further obstacle is the general lack of awareness concerning the benefits of honeycomb core structures in industries such as aerospace, automotive, and construction, which can suppress market growth. In addition, the volatility of raw material prices can negatively affect manufacturers' profit margins, complicating the ability to offer competitive pricing. The presence of alternative materials, like solid composites and foams, also constitutes a persistent challenge, as customers may prefer options that are more familiar or easily accessible.

However, the growing focus on lightweight and energy-efficient materials across various sectors offers a significant opportunity for the honeycomb core materials market to innovate and develop. As sustainability continues to gain importance, the increasing demand for high-performance, lightweight solutions is poised to stimulate growth, heralding a promising future for this adaptable material.

Key Segments of the Honeycomb Core Materials Market

By Type

• Aluminum

• Paper

• Nomex

• Thermoplastic

• Others

By End User

• Composites

• Non-Composites

By Application

• Packaging

• Aerospace & Defense

• Construction & Infrastructure

• Transportation

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America