Green Electronics Manufacturing Market Analysis and Insights:

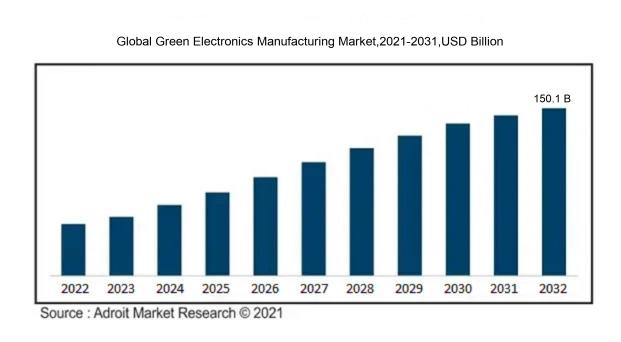

In 2023, the size of the worldwide Green Electronics Manufacturing market was US$ 29.03 billion. Adroit Market Research projects that the market will increase at a compound annual growth rate (CAGR) of 20.02 % from 2024 to 2032, reaching US$ 150.1 billion.

The Green Electronics Manufacturing sector is driven by numerous influential factors, including ened environmental regulations, growing consumer consciousness regarding sustainable practices, and an increasing desire for energy-efficient products. The emphasis on corporate sustainability has encouraged manufacturers to integrate environmentally friendly materials and processes into their operations, not only to meet rigorous regulatory standards but also to improve their brand reputation. Advances in recycling technologies and waste management are enabling more sustainable production techniques, thereby minimizing the environmental impact of electronic products. Moreover, government support through incentives and subsidies aimed at green technologies is promoting investments in sustainable manufacturing approaches. The escalating demand for electric vehicles, renewable energy solutions, and smart devices—which often utilize eco-conscious components—further accelerates market development. Together, these elements establish a strong foundation for the growth and enhancement of green electronics manufacturing, aligning industry practices with global objectives for sustainability.

Green Electronics Manufacturing Market Definition

Green electronics manufacturing denotes the creation of electronic devices through environmentally responsible methods, aimed at reducing both waste and energy usage. This approach prioritizes the incorporation of sustainable materials and practices to lessen the ecological footprint of electronic goods.

Eco-friendly electronics production plays a pivotal role in achieving sustainable development by reducing the ecological footprint of electronic goods throughout their entire lifecycle. This methodology emphasizes waste reduction, resource conservation, and the use of renewable materials, effectively curbing pollution and lowering greenhouse gas emissions. With the escalating global demand for electronic devices, it is imperative to implement environmentally conscious practices to safeguard natural ecosystems and human well-being. Additionally, green manufacturing not only ensures compliance with increasingly rigorous regulations but also aligns with consumer demands for sustainable offerings, thereby promoting innovation and establishing a competitive edge in the market. Adopting these practices is essential for fostering a harmonious relationship between technological advancement and environmental stewardship.

Green Electronics Manufacturing Market Segmental Analysis:

Insights On Product Type

Green Smartphones

Green Smartphones are poised to dominate the Global Green Electronics Manufacturing Market due to escalating demand for eco-friendly mobile devices among environmentally conscious consumers. The growing penetration of smartphones globally, combined with technological advancements favoring sustainability, has led manufacturers to invest in eco-friendly materials and greener production processes. Additionally, governmental regulations promoting sustainability in electronics are prompting smartphone companies to adopt practices that reduce energy consumption and waste. This convergence of consumer preferences and regulatory pressures is minting Green Smartphones as the frontrunner in the green electronics domain.

Green Computers

Green Computers are increasingly gaining traction as consumers and businesses aim to reduce their carbon footprint. Innovations focused on energy efficiency, such as hardware that consumes less power and the use of recyclable materials, play a significant role in this growth. Furthermore, the rise of remote work culture has spurred demand for eco-friendly computing solutions that combine performance with sustainability.

Green Smart Home Appliances

Green Smart Home Appliances are witnessing a steady uptick in demand as smart home technology integrates energy-efficient features. Consumers are now more aware of their ecological impact and seek appliances that offer connectivity while minimizing energy use. As smart homes become more prevalent, the emphasis on appliances that follow green manufacturing practices will continue to grow, albeit at a slower pace compared to smartphones.

Green Wearable Electronics

Green Wearable Electronics are observing gradual growth driven by health and wellness trends. Devices such as fitness trackers and smartwatches that incorporate eco-friendly materials are appealing to health-conscious consumers. However, their market share remains lower compared to smartphones, as wearables still represent a smaller within the overall electronics market focused on sustainability.

Green Industrial Electronics

Green Industrial Electronics are essential for sustainable manufacturing processes and energy management. This is supported by industries aiming to incorporate greener practices to meet regulatory standards and improve efficiency. Nonetheless, their growth is slower compared to consumer-oriented products like smartphones, as industrial applications typically undergo longer sales cycles and require significant investment in technology and changes in infrastructure.

Insights On Material Type

Low-Power Components

The dominating element in the Global Green Electronics Manufacturing Market is anticipated to be low-power components. These components are integral to the development of energy-efficient devices, which are increasingly in demand due to rising energy costs and stringent regulatory frameworks aimed at reducing carbon footprints. As technological advancements progress, low-power components allow manufacturers to create products that not only consume less energy but also extend battery life, thus enhancing user satisfaction. Furthermore, the lighting and power sectors are rapidly transitioning towards sustainable solutions, emphasizing the need for components that align with eco-friendly manufacturing practices. This trend indicates a future where low-power components will lead the green electronics sector.

Recycled/Reused Plastics

Recycled and reused plastics have emerged as a pivotal choice in the green electronics manufacturing landscape. Their significance lies in their ability to reduce waste and lower the demand for virgin plastic production. As consumers increasingly prioritize sustainability, companies are responding by integrating these materials into their production processes. This not only aligns with global recycling initiatives but also helps manufacturers differentiate their products as environmentally friendly. The ongoing innovation in recycling technologies is expected to further enhance the efficiency of incorporating recycled plastics, making this choice crucial for achieving sustainability goals in electronics.

Biodegradable Materials

Biodegradable materials are gaining traction within the green electronics manufacturing sector due to their potential to minimize environmental impact. These materials offer the advantage of breaking down naturally over time, thus reducing landfill waste and pollution associated with conventional plastics. As environmental regulations tighten globally, manufacturers are under pressure to incorporate greener alternatives in their product designs. The development of biodegradable options is rapidly progressing, driven by both consumer awareness and market demand, positioning them as a viable option for companies seeking to bolster their eco-friendly credentials in electronics.

Energy-Efficient Displays

Energy-efficient displays constitute a vital component within green electronics, aiming to reduce energy consumption while maintaining high-performance standards. As the push for energy conservation grows, these displays can lower the power requirements of devices, thereby contributing to overall sustainability in manufacturing. Additionally, advancements in display technologies, such as OLED and LCD technologies that are designed with energy efficiency in mind, promise longer lifespans and improved functionality. The continuous innovation in this area is crucial as manufacturers strive to comply with energy regulations and consumer expectations regarding sustainable products.

Lead-Free Solder

Lead-free solder is becoming increasingly relevant in the green electronics manufacturing arena due to health and environmental considerations surrounding lead usage. With directives such as RoHS (Restriction of Hazardous Substances) promoting the elimination of hazardous materials, lead-free alternatives are gaining ground. This transition not only helps companies ensure compliance with regulatory standards but also reflects a growing commitment to producing safer and more sustainable electronics. The ongoing research into various lead-free solder formulations indicates significant advancements, enabling manufacturers to maintain product reliability while adhering to environmental standards.

Insights On Process Type

Design for Environment (DfE)

Among the various processes in the Global Green Electronics Manufacturing Market, Design for Environment (DfE) is expected to dominate significantly. DfE focuses on integrating environmental considerations during the product design phase, encouraging innovation for sustainable materials and energy-efficient processes. Companies increasingly prioritize sustainable design to reduce the environmental footprint of electronic devices throughout their life cycles. Pressure from consumers, regulatory bodies, and corporate sustainability goals has moved DfE to the forefront, as it not only addresses ecological concerns but also contributes to cost savings and compliance with environmental regulations. As a result, DfE's strategic importance in fostering sustainable technologies makes it the leading approach in this market.

Life Cycle Assessment (LCA)

Life Cycle Assessment (LCA) is a critical method used to evaluate the environmental impacts associated with all the stages of a product's life from cradle to grave. By providing comprehensive data on resource usage and emissions, LCA enables companies to make informed decisions about their ecodesign initiatives. It highlights areas for improvement and encourages industries to innovate in material selection and production methods. However, while LCA is essential for measuring sustainability performance, its complexity and resource intensity can limit its practical application in daily manufacturing processes compared to the more proactive DfE approach.

Waste Reduction Techniques

Waste Reduction Techniques aim to minimize waste generation and promote recycling within the manufacturing processes of electronics. This approach plays a vital role in the green electronics sector, particularly as governments and organizations implement stringent regulations to manage electronic waste effectively. Techniques include redesigning processes to improve efficiency, utilizing waste audits, and fostering a culture of sustainability. While important, this approach often focuses on addressing issues generated post-production rather than reshaping the foundational design of products, which may limit its overall transformative impact compared to DfE.

Energy Conservation Measures

Energy Conservation Measures encompass strategies aimed at reducing energy consumption during the manufacturing and operational phases of electronics production. These practices are crucial for minimizing the carbon footprint and operational costs of manufacturers. They often involve upgrading equipment, optimizing processes, and investing in renewable energy sources. Although these measures are vital for sustainability, they tend to complement the broader strategies offered by DfE instead of serving independently as a primary approach. Energy efficiency is critical but needs to be integrated holistically with product design and lifecycle considerations to achieve the greatest impact.

Zero Waste Manufacturing

Zero Waste Manufacturing is a goal that seeks to redesign industrial processes so that all materials are reclaimed, reused, or recycled, effectively creating a closed-loop system. This method significantly reduces waste and promotes the sustainable use of resources. It can lead to substantial cost savings and environmental benefits. However, Zero Waste practices often rely on existing systems' efficiency, which requires substantial commitment and changes in corporate culture. While noble in intent, it often finds itself less prioritized compared to proactive design approaches that fundamentally alter how products are conceived and produced for sustainability.

Insights On Certification

EPEAT

EPEAT (Electronic Product Environmental Assessment Tool) is anticipated to dominate the Global Green Electronics Manufacturing Market due to its comprehensive framework for evaluating the environmental performance of electronics. With an increasing focus on sustainability, manufacturers are increasingly adopting EPEAT standards to demonstrate their commitment to eco-friendly practices. EPEAT certification not only helps in reducing environmental impacts but also enhances brand reputation and consumer trust, which are crucial in today's competitive landscape. The growing demand for certified green products among consumers and regulatory bodies strongly supports EPEAT's leading position in the market, making it the preference for manufacturers aiming to achieve sustainability objectives.

Supply Chain Analytic Applications

Supply Chain Analytic Applications are essential for optimizing resource use and reducing waste throughout the manufacturing process. These tools allow companies to monitor their supply chain's environmental impact, ensuring compliance with green standards. As manufacturers seek better insights to enhance efficiency and minimize their carbon footprints, these applications play a critical role. Their effectiveness in data analytics and real-time tracking can significantly improve decision-making processes, creating a more streamlined and sustainable manufacturing workflow.

Green Electronics Council (GEC)

The Green Electronics Council (GEC) plays a pivotal role in promoting sustainable practices within the electronics industry. By providing programs and resources for eco-labeling, GEC helps manufacturers navigate the complexities of green certifications. Their initiatives boost awareness about the importance of environmental responsibility, thus influencing manufacturers to adopt greener practices. Although not the primary certification leader, the GEC’s efforts enhance the overall shift toward sustainable electronics and increase the visibility of environmentally-friendly products in the marketplace.

UL Environment

UL Environment offers certifications that focus on product safety and sustainability, which are crucial for manufacturers aiming to meet stringent environmental regulations. Their standards address various aspects, including materials sourcing and energy efficiency, making them an attractive choice for companies seeking to showcase their commitment to sustainability. While gaining traction, UL Environment still relies on broader industry recognition and market adoption to compete with leading certifications, contributing to the growing movement towards environmentally-conscious manufacturing in the electronics sector.

ISO 14001

ISO 14001 certification emphasizes the establishment of effective environmental management systems, which can significantly enhance a company's sustainability practices. Many organizations are adopting this standard to demonstrate their commitment to continuous improvement and compliance with environmental regulations. While ISO 14001 provides a structured approach to managing environmental responsibilities, its adoption is often slow due to the complexity of implementation processes. Nevertheless, as businesses increasingly recognize the importance of sustainable practices, ISO 14001 remains a relevant option for those aspiring to strengthen their environmental performance.

Insights On End-use

Consumer Electronics

Consumer Electronics is expected to dominate the Global Green Electronics Manufacturing Market due to the increasing consumer demand for energy-efficient products. As technology advances, manufacturers are focusing on developing eco-friendly devices such as smartphones, laptops, and home appliances that consume less power and are made from sustainable materials. Moreover, the rising awareness regarding environmental issues and the implementation of regulations aimed at reducing carbon footprints further facilitate the growth of green electronics in this sector. The consumer electronics market is also significantly driven by the rapid proliferation of smart devices, enhancing its relevance and importance in the green manufacturing space.

Healthcare

Healthcare is an important sector in the Global Green Electronics Manufacturing Market, noted for the growing emphasis on sustainable practices and environmentally friendly products. Medical devices and equipment are increasingly manufactured following eco-friendly standards, responding to the need for efficient waste management and energy consumption. As healthcare systems seek to minimize their environmental impact while maintaining high standards of patient care, the demand for green electronics will likely rise, promoting innovation and sustainability in the healthcare industry.

Automotive

In the automotive industry, sustainability is becoming crucial due to increasing regulations on emissions and the growing environmental concerns of consumers. Electric vehicles (EVs) are at the forefront of this transformation, requiring innovative green electronics to ensure efficiency and safety. Manufacturers are investing heavily in developing more sustainable power systems, such as batteries and lightweight materials, to enhance performance while reducing the carbon footprint. This drive towards sustainability within the automotive sector supports its growth in the green electronics manufacturing market.

Industrial

The industrial sector is moving towards greener practices, focusing on manufacturing processes that minimize waste while increasing productivity. The adoption of green electronics in industries is motivated by the rising costs of energy and the need to comply with environmental regulations. Many industrial operators are integrating energy-efficient components in their machinery and equipment to reduce operational costs and improve sustainability. This transition toward greener methods makes the industrial sector a noteworthy participant in the green electronics manufacturing arena, as more companies prioritize eco-friendly practices.

Government

The government plays a vital role in the Global Green Electronics Manufacturing Market by establishing regulations and frameworks supporting sustainability initiatives. Governments around the world are implementing policies to promote green technologies and environmentally friendly practices across various sectors. These policies can include incentives for manufacturers to develop sustainable products or restrictions on the use of hazardous materials in electronics. As a result, the government sector indirectly influences the growth of green electronics manufacturers, encouraging the adoption of eco-conscious practices throughout the supply chain.

Global Green Electronics Manufacturing Market Regional Insights:

Asia Pacific

Asia Pacific is set to dominate the Global Green Electronics Manufacturing market due to several pivotal factors. This region is currently experiencing robust industrial growth and urbanization, leading to increased demand for electronic products, which necessitates sustainable manufacturing practices. The presence of major electronic manufacturers in countries like China, Japan, and South Korea, coupled with substantial investments in green technology, further strengthens its position. Moreover, supportive government policies aimed at reducing carbon footprints and encouraging eco-friendly business practices make Asia Pacific a leader in green electronics innovations. The region also benefits from a strong supply chain and availability of skilled labor, contributing to its competitiveness in the green electronics sector.

North America

North America is another significant player in the Global Green Electronics Manufacturing market, driven by stringent regulations regarding environmental sustainability and waste management. The United States and Canada have made considerable investments in green technology and renewable energy, prompting electronics manufacturers to adopt environmentally friendly practices. Additionally, consumer preferences in this region are shifting towards sustainable products, pressuring companies to innovate and implement greener manufacturing processes. This growing awareness provides opportunities for development in the green electronics arena, ensuring North America's relevance in the global market.

Latin America

Latin America’s position in the Global Green Electronics Manufacturing market is gradually improving due to an increasing emphasis on sustainability and environmental care. Countries such as Brazil and Mexico are initiating policies to promote green technology and reduce electronic waste. However, the region still faces challenges in infrastructure and investment, limiting its growth potential. Despite these obstacles, emerging local manufacturers are beginning to adopt greener practices, and as awareness grows among consumers, the demand for sustainable electronics is projected to rise, fostering future market opportunities.

Europe

Europe is recognized for its progressive stance on environmental sustainability, making it a notable contender in the Global Green Electronics Manufacturing market. The European Union has established stringent regulations aimed at promoting eco-friendly manufacturing and reducing electronic waste, compelling manufacturers to adopt sustainable practices. These regulatory frameworks, combined with a high level of consumer awareness about environmental issues, drive demand for green electronics across the continent. While Europe is a leader, the intensity of competition among countries could impact its overall dominance in the future, as enterprises navigate ever-evolving consumer expectations and compliance requirements.

Middle East & Africa

The Middle East & Africa face considerable challenges in the Global Green Electronics Manufacturing market, primarily due to a lack of infrastructure and limited investment in green technologies. However, there is a burgeoning interest in sustainability driven by growing populations and the awareness of environmental issues. Countries like South Africa are exploring paths to incorporate green manufacturing practices as a part of their development strategies. Although the market is still in its nascent stage compared to others, potential growth opportunities exist, particularly if more investments are made to enhance regional capabilities and promote eco-friendly technologies in the electronics sector.

Green Electronics Manufacturing Market Competitive Landscape:

Leading figures in the global green electronics manufacturing sector spearhead advancements by creating sustainable materials and optimizing production methods for energy efficiency. They remain compliant with sustainability standards and regulations, fostering partnerships within the supply chain that promote the adoption of environmentally friendly practices across all stages of manufacturing and distribution.

Significant participants in the Green Electronics Manufacturing sector encompass Samsung Electronics Co., Ltd., LG Electronics Inc., Sony Corporation, Apple Inc., Dell Technologies Inc., HP Inc., Panasonic Corporation, Fujitsu Limited, Sharp Corporation, Toshiba Corporation, Microsoft Corporation, Intel Corporation, Qualcomm Incorporated, Hon Hai Precision Industry Co., Ltd. (known as Foxconn), and Celestica Inc.

Global Green Electronics Manufacturing Market COVID-19 Impact and Market Status:

The Covid-19 pandemic had a profound impact on the Global Green Electronics Manufacturing sector, leading to disruptions in supply chains, changes in consumer preferences, and hastening the transition towards environmentally friendly production methods.

The COVID-19 pandemic had a profound effect on the green electronics manufacturing sector. Initially, it led to significant disruptions including supply chain interruptions, the temporary closure of factories, and limitations on workforce availability. These factors resulted in production delays and a short-term drop in consumer demand as priorities shifted. Conversely, the crisis acted as a catalyst for the adoption of sustainable practices. Businesses and consumers alike became increasingly aware of environmental issues, driving the demand for green technologies. The rise in remote work and digital transformation sparked innovations in energy-efficient products and the use of recyclable materials. Additionally, government stimulus measures and support for sustainable initiatives further strengthened the market. As economies began to rebound, the emphasis on environmental sustainability intensified, resulting in a renewed interest in investments within green electronics manufacturing. By embracing eco-friendly practices and technologies, the sector is well-positioned for growth, anticipating long-term advantages as sustainability becomes a central element of the global electronics industry.

Latest Trends and Innovation in The Global Green Electronics Manufacturing Market:

- In March 2023, Apple announced its commitment to using 100% recycled aluminum in all of its products, which is part of the company's broader initiative to reduce its carbon footprint by 2030 and promote sustainable manufacturing practices.

- In July 2023, Samsung Electronics launched its Eco-Friendly packaging initiative, aiming to eliminate plastic packaging from its products by 2025. This move includes utilizing paper and other sustainable materials for packaging solutions.

- In September 2023, LG Electronics announced the acquisition of a minority stake in a startup focusing on sustainable battery technologies. This partnership aims to accelerate innovations in electric vehicle batteries and expand LG's portfolio in the green electronics sector.

- In June 2023, Tesla revealed plans to establish a new gigafactory in Texas dedicated to the production of energy storage technologies and solar products, enhancing its sustainability efforts and decreasing reliance on non-renewable energy sources.

- In April 2023, Dell Technologies launched a new line of laptops dubbed the "Latitude Series," which features up to 50% recycled materials in their construction, setting a new standard within the industry for sustainable electronics.

- In December 2023, Panasonic announced a merger with the renewable energy firm Eco Technologies to enhance its capabilities in solar panel manufacturing, aiming to leverage combined expertise to drive forward green energy solutions.

- In February 2023, Siemens AG revealed advancements in its sustainable production technology, focusing on smart manufacturing processes that reduce waste and energy consumption, significantly enhancing their green production methodologies.

Green Electronics Manufacturing Market Growth Factors:

The expansion of the Green Electronics Manufacturing sector is fueled by ened environmental regulations, a surge in consumer desire for sustainable goods, and innovations in environmentally friendly technologies.

The advancement of the Green Electronics Manufacturing sector is influenced by a variety of elements. Heightened awareness of environmental issues among both consumers and regulatory authorities is encouraging manufacturers to integrate sustainable materials and practices into their operations. Stringent regulations concerning the management of electronic waste and the reduction of harmful substances are pressuring companies to explore innovative, eco-friendly designs and processes. Furthermore, the increase in disposable incomes, along with a rising consumer preference for energy-efficient and sustainable options, is driving demand for green electronic products. Progress in technological innovation and materials science is facilitating the creation of recyclable and biodegradable components, which further supports the growth of this market. The urgency for energy-efficient electronic devices to minimize operational expenses is prompting manufacturers to proactively invest in sustainable technologies. In addition, corporate commitments to sustainability and efforts to lower carbon emissions are fostering collaborations and partnerships, all aimed at developing environmentally responsible electronics. The growth of a circular economy, focused on the reuse and recycling of materials, also significantly influences market trends. Collectively, these factors are contributing to a transformation toward more sustainable manufacturing approaches, thereby opening up new avenues for expansion within the Green Electronics Manufacturing sector.

Green Electronics Manufacturing Market Restaining Factors:

The Green Electronics Manufacturing sector faces obstacles due to elevated production expenses and difficulties in acquiring sustainable materials.

The Green Electronics Manufacturing Sector encounters various obstacles that could impede its growth and wider acceptance. One significant barrier is the substantial investment required for the development and adoption of environmentally friendly technologies, which can deter small and medium enterprises from embracing sustainable practices. Moreover, the absence of uniform regulations and certifications related to green electronics can lead to confusion for both producers and consumers, thereby hindering market development. Access to sustainable materials and components is also limited, given that many conventional suppliers have yet to provide eco-friendly options. Additionally, the swift advancement of technology can make it challenging to incorporate green initiatives into current manufacturing processes. While consumer awareness and demand for green electronics fluctuate, many consumers still prioritize cost-effectiveness and performance over their ecological footprint. Nonetheless, as global consciousness regarding environmental challenges grows, coupled with rising government support and regulations advocating for sustainability, there exists a promising opportunity for innovation and growth in the green electronics industry. By tackling these hindrances and committing to sustainable practices, the sector can lead the way toward a more environmentally responsible future, ultimately benefiting both manufacturers and their customers.

Segments of the Green Electronics Manufacturing Market

By Product Type

- Green Computers

- Green Smartphones

- Green Smart Home Appliances

- Green Wearable Electronics

- Green Industrial Electronics

By Material Type

- Recycled/Reused Plastics

- Biodegradable Materials

- Low-Power Components

- Energy-Efficient Displays

- Lead-Free Solder

By Process Type

- Life Cycle Assessment (LCA)

- Design for Environment (DfE)

- Waste Reduction Techniques

- Energy Conservation Measures

- Zero Waste Manufacturing

By Certification

- Supply Chain Analytic Applications

- EPEAT

- Green Electronics Council (GEC)

- UL Environment

- ISO 14001

By End-use

- Consumer Electronics

- Healthcare

- Automotive

- Industrial

- Government

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America