Functional Coating Market Analysis and Insights:

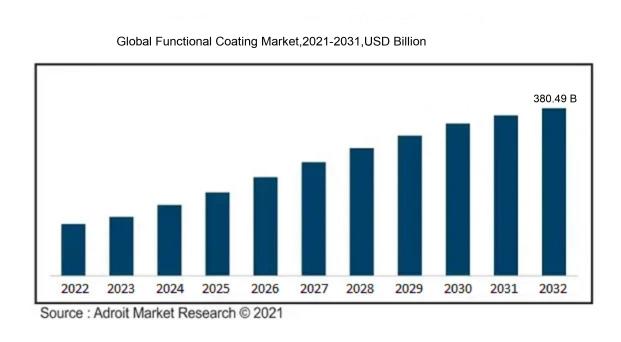

In 2023, the size of the worldwide Functional Coating market was US$ 203.52 billion. Adroit Market Research projects that the market will increase at a compound annual growth rate (CAGR) of 7.2% from 2024 to 2032, reaching US$ 380.49 billion.

The Functional Coating Market is driven by several pivotal factors. Firstly, the surge in demand for innovative materials across sectors like automotive, electronics, and construction significantly propels the growth of functional coatings, which improve both product performance and durability. Advancements in coating technologies, including the use of nanomaterials and eco-friendly options, are redefining the market, aligning with consumer preferences for sustainable alternatives. Moreover, stringent environmental regulations and the push for energy-efficient solutions are encouraging manufacturers to develop cutting-edge coatings that provide protective qualities, including resistance to corrosion and antimicrobial effects. The increasing prevalence of automation and smart technologies in the manufacturing sector further broadens the scope of functional coatings, promoting their application. Additionally, the expansion of industrial sectors in emerging economies fuels the adoption of these specialized coatings, further driving market growth.

Functional Coating Market Definition

Functional coatings are tailored layers applied to surfaces to provide advantageous characteristics such as resistance to water, protection against ultraviolet light, and prevention of corrosion. These coatings significantly improve the usability and effectiveness of materials across a range of applications.

Functional coatings play an essential role in improving the performance and longevity of various substrates in multiple applications. They enhance attributes like resistance to corrosion, abrasion, and chemical exposure, which consequently prolongs product lifespan. Furthermore, these coatings can provide specialized features, including water repellency, antimicrobial properties, and thermal insulation, addressing the specific requirements of industries such as automotive, aerospace, electronics, and healthcare. By maximizing these beneficial properties, functional coatings not only increase the efficiency and dependability of products but also bolster sustainability initiatives by lowering maintenance expenses and conserving resources over time.

Functional Coating Market Segmental Analysis:

Insights On Function

Anti-Corrosion

The Anti-Corrosion function is expected to dominate the Global Functional Coating Market due to the rising demand from industries such as automotive, marine, and construction. These sectors require effective solutions to combat the detrimental effects of corrosion on metals and alloys. As awareness increases regarding the importance of protective coatings in extending the lifespan of products and reducing maintenance costs, the adoption of Anti-Corrosion coatings is set to surge. Additionally, regulatory standards pushing for environmentally sustainable practices propel the use of advanced anti-corrosive materials that deliver performance without compromising safety or environmental health. The market's trajectory towards eco-friendly innovations makes this category a significant leading force.

Anti-Microbial

The Anti-Microbial category is experiencing substantial growth, driven by increasing concerns over health and hygiene, especially in sectors such as healthcare, food processing, and consumer products. With the ongoing challenges of infectious diseases, there is ened demand for coatings that provide protection against microorganisms. This function not only simplifies cleaning processes in hospitals and laboratories but also enhances product durability in everyday items. Furthermore, the expanding awareness regarding clean and hygienic environments in residential and commercial spaces bolsters the market's expansion in this area, making it a crucial component in functional coatings.

Anti-Scratch

The Anti-Scratch function is gaining attention primarily in industries like electronics, automotive, and consumer goods. As products become sleeker and more refined, the demand for protective coatings that maintain aesthetic integrity while ensuring durability becomes paramount. This function caters to the growing consumer preference for long-lasting, visually appealing items. Moreover, the growth of smart devices, which often come with sensitive screens and surfaces, adds to the necessity of effective anti-scratch solutions. This increasing need encourages innovation and product development, contributing to a favorable market landscape.

Self-Cleaning

The Self-Cleaning function is evolving, especially in sectors such as building materials, textiles, and automotive. With urbanization on the rise, there is an increasing need for surfaces that resist dirt and grime buildup, reducing the need for maintenance. This category leverages advancements in nano-technology and surface chemistry to create coatings that repel water and dirt effectively. Consumer preferences for low-maintenance options further drive market growth. As advances continue, self-cleaning solutions are expected to become increasingly popular, particularly in urban environments where cleanliness is a major concern.

Heat Insulation

Heat Insulation is emerging as a player due to the escalating emphasis on energy efficiency and sustainability across various industries. This function is particularly vital in construction and manufacturing, where energy conservation plays a significant role in operational costs. With increasing energy costs and regulatory pushes towards greener building practices, the demand for effective thermal management solutions is on the rise. In addition, the growing focus on reducing carbon footprints promotes the adoption of heat insulation coatings, which contribute to lower energy consumption in residential and commercial settings. This cultural shift towards sustainability drives interest and investment in this area of functional coatings.

Insights On Material

Polymers

Polymers are expected to dominate the Global Functional Coating Market due to their versatile properties and cost-effectiveness. They offer excellent flexibility, adhesion, and chemical resistance, making them suitable for various applications across industries such as automotive, electronics, and construction. The increasing demand for lightweight and durable materials has further propelled the use of polymers in functional coatings. Moreover, advancements in polymer chemistry have led to the development of specialized coatings that can enhance performance and longevity, catering to specific market needs. The growing trend toward sustainable and eco-friendly materials is also pushing manufacturers to explore biodegradable polymers, which is anticipated to drive market growth in this domain.

Ceramics

Ceramics are increasingly gaining traction in the Functional Coating Market due to their unique properties, such as high-temperature resistance, hardness, and excellent chemical stability. These characteristics make ceramic coatings particularly appealing for applications in aerospace, automotive, and energy sectors, where durability and reliability are paramount. The rise in demand for thermal barrier coatings and abrasion-resistant coatings is further propelling the ceramics. Additionally, technological advancements in the production of advanced ceramics are enabling more effective coating solutions, thereby driving their adoption across various industries.

Metals

Metal coatings are crucial in the Functional Coating Market, primarily due to their superior electrical conductivity and mechanical strength. They are commonly used in applications like electronics and automotive components, where robustness and performance are critical. The rising need for protective coatings to enhance the lifespan of metal substrates against corrosion and wear is contributing to growth in the metal coatings. However, challenges such as heavy weight and susceptibility to rust could limit their growth compared to lighter alternatives. Nonetheless, innovations in metal coating technologies are helping to mitigate these issues, thus sustaining interest in this.

Graphene

Graphene coatings are emerging as a promising option in the Functional Coating Market due to their exceptional electrical conductivity, mechanical strength, and thermal performance. Primarily utilized in high-tech applications, graphene coatings are gaining popularity in sectors like electronics and energy storage, where performance and efficiency are critical. However, the high cost associated with graphene production and the current technological limitations hinder mass adoption. As research progresses and production methods improve, there may be greater opportunities for graphene to capture market share, especially for applications requiring advanced materials with superior properties.

Carbon Nanotubes

Carbon Nanotubes (CNTs) are recognized for their remarkable mechanical and electrical properties, making them an attractive option in the Functional Coating Market. These materials are often utilized in high-performance applications, particularly in industries like electronics and telecommunications, where conductivity plays a pivotal role. However, the adoption of CNTs can be constrained by factors such as high production costs and challenges related to dispersion in coatings. Despite these hurdles, ongoing research into reducing costs and improving CNT integration continues to make them a of growth potential, especially for niche applications that demand advanced material characteristics.

Insights On Coating Method

Spray Coating

Spray Coating is expected to dominate the Global Functional Coating Market due to its versatility and efficiency in application across various industries. This method allows for the even distribution of coatings, ensuring a uniform finish while significantly reducing material wastage. The growing demand for protective coatings in automotive, aerospace, and electronics sectors further reinforces its prominence. Additionally, advancements in spray technology, including airless and electrostatic spray systems, have improved the quality and precision of coatings. These innovations, coupled with the increasing focus on sustainability and eco-friendly products, position Spray Coating as the preferred choice for manufacturers seeking high-performance and environmentally responsible solutions.

Dip Coating

Dip Coating is a method favored for its simplicity and cost-effectiveness, particularly when a thick layer of coating is needed. This technique is widely utilized in the production of enamel-coated metals and in applications requiring strong adhesion, such as glass and ceramics. Industries like automotive and consumer goods benefit from the substantial coatings produced through dip methods. Moreover, its ability to coat objects of irregular shapes consistently adds to its appeal, despite the steady growth of other methods. However, limitations such as slower drying times and challenges in achieving uniformity on larger surfaces do exist.

Roller Coating

Roller Coating is recognized for its efficiency in high-speed applications, especially in the wood, paper, and packaging sectors. This technique provides a smooth and even distribution of coatings, making it suitable for large surface areas. While Roller Coating is efficient in terms of production speed and material usage, it often requires pre-treated surfaces to achieve the best final results. Its popularity is linked to the demand for continuous production processes; however, it may not be suitable for all types of coatings, especially those requiring intricate patterns or custom textures, which can hinder its overall market growth.

Vapor Deposition

Vapor Deposition is a highly specialized technique primarily used in electronics and optics. It offers a precise application method that is essential for creating thin films and coatings with uniform thickness at the molecular level. This quality makes it invaluable in industries where performance and reliability are critical, such as semiconductors and solar cells. However, the complexity of the equipment and the costs associated with the process can limit its usage to specific applications. While it excels in producing high-quality coatings, the niche nature of Vapor Deposition contributes to its relatively smaller market share compared to more versatile methods like Spray Coating.

Spin Coating

Spin Coating is recognized for its ability to achieve thin, uniform coatings on flat substrates, making it especially popular in the fields of microelectronics and photolithography. With its rapid application technique, Spin Coating allows for precise control over the thickness of the coating, which is crucial for many high-tech applications. The process is highly efficient and tends to minimize waste, aligning well with the growing emphasis on sustainability. However, its applicability is largely limited to planar surfaces, restricting its usage in more diverse industries compared to other methods like Spray Coating or Dip Coating, which can handle a wider array of forms and materials.

Insights On Curing Process

UV Curing

UV Curing is expected to dominate the Global Functional Coating Market due to its rapid processing speed, which enables high production efficiency. The technology uses ultraviolet light to cure coatings instantly, making it favorable in industries such as automotive, electronics, and packaging. Additionally, UV Curing offers excellent environmental benefits since it emits lower levels of volatile organic compounds (VOCs) compared to traditional methods. The growing emphasis on sustainable manufacturing processes and stringent environmental regulations further enhance its attractiveness. With advancements in UV technology and an increasing number of applications, UV Curing is set to lead the market in the coming years.

Thermal Curing

Thermal Curing involves applying heat to accelerate the curing process and is widely used in various industries, including automotive and aerospace. Although it's a traditional method, it offers consistent performance for coatings requiring durable finishes. However, it can be slower compared to UV methods, leading to longer production times. Market challenges include increased energy consumption and higher operational costs, as maintaining optimal temperatures for curing can be expensive. Nevertheless, Thermal Curing remains prevalent due to its compatibility with numerous substrates and applications.

Electron Beam Curing

Electron Beam Curing (EBC) utilizes high-energy electrons to initiate polymerization, providing a fast and effective means to cure coatings. This technology features minimal VOC emissions and results in coatings with exceptional hardness and chemical resistance. EBC is primarily used in specialized applications such as industrial coatings and electronics. However, the high initial investment and complex equipment needed for EBC may limit its widespread adoption. As industries pursue high-performance coatings, Electron Beam Curing has the potential to find niche markets where its unique properties can be fully leveraged.

Microwave Curing

Microwave Curing is a less conventional technique that leverages microwave radiation to generate heat and cure coatings. While this method can offer rapid curing times and uniform heat distribution, it is not yet widely adopted compared to other techniques. industries involving high-performance coatings are exploring Microwave Curing for niche applications. Its main challenges include the requirement for specialized equipment and the need for further research to optimize processes and material compatibility. Consequently, while it offers promising advantages, Microwave Curing still has a limited presence in the global market.

Laser Curing

Laser Curing employs focused laser beams to achieve rapid curing of coatings, primarily utilized in precise applications within the electronics and medical sectors. This method offers the advantage of localized heating, which can minimize substrate perturbation and provide excellent finish quality. However, the technology requires intricate setups and operational know-how, which can impose limitations on its broader application across various industries. Although Laser Curing holds potential for high-value applications, its adoption is often constrained by cost and technological complexity, keeping it from leading the market as effectively as other methods.

Insights On Application

Electronics

The electronics sector is expected to dominate the global functional coating market due to its rapid growth and advances in technology. The increasing need for innovative and efficient electronic devices, such as smartphones, tablets, and wearables, drives the demand for functional coatings that provide essential features like anti-reflective surfaces, hydrophobic properties, and corrosion protection. Moreover, the trend toward miniaturization and enhanced functionality in electronic components calls for specialized coatings that not only protect devices but also improve performance and longevity. As electronic devices continue to evolve at a fast pace, this will likely outpace others in terms of market growth and revenue generation.

Automotive

The automotive sector is significant within the functional coating market, primarily because of the rising standards for vehicle performance and aesthetics. As consumers demand greater durability and efficiency in vehicles, coatings that provide anti-corrosive properties, UV resistance, and self-cleaning features are increasingly prioritized. Moreover, the shift toward electric vehicles and their unique requirements for lightweight yet resilient coatings is also expected to contribute to the growth of this. The integration of coatings that enhance the longevity and appeal of vehicles remains a driver, making it a vital area within the market.

Medical

The medical application of functional coatings holds substantial importance, particularly as healthcare technology continues to advance. Coatings used in medical devices must offer specific functionalities such as biocompatibility, antimicrobial properties, and enhanced durability. These features are crucial in improving patient safety and the overall effectiveness of medical instruments. The ongoing developments in drug delivery systems and implantable devices further fuel the demand for specialized coatings, solidifying the medical sector as a player in the functional coatings market.

Aerospace

The aerospace industry significantly contributes to the global functional coating market as it requires coatings that can withstand extreme conditions. These coatings must possess features like thermal resistance, anti-corrosion, and weight reduction, ensuring that aircraft components maintain both safety and performance standards. Advanced coatings that enhance fuel efficiency and reduce maintenance costs are particularly valuable in this sector. While the growth is steady, the unique requirements of aerospace coatings make this essential but less dominant compared to electronics.

Marine

Marine applications represent a crucial aspect of the functional coating market, particularly in terms of protection against harsh environmental conditions. Coatings used in marine settings must resist corrosion, biofouling, and extreme weather, which adds a layer of complexity to their formulation. As the shipping industry strives for durability and longevity of vessels, the demand for specialized coatings grows. Despite its importance, the marine typically faces growth challenges compared to the electronics and automotive sectors, reflecting a smaller overall market share within functional coatings.

Global Functional Coating Market Regional Insights:

Asia Pacific

Asia Pacific is poised to dominate the Global Functional Coating market due to several driving factors, including rapid industrialization, increasing consumer electronics demand, and significant investments in construction and automotive sectors. Countries like China, India, and Japan are experiencing a surge in manufacturing activities as well as infrastructural developments, leading to higher consumption of functional coatings. Furthermore, the region is witnessing technological advancements in coating materials, resulting in more efficient, durable, and sustainable products. The rising awareness about protective coatings in various industries and an overall increase in disposable incomes contribute to the growth of this, establishing Asia Pacific as a player in the functional coating market.

North America

North America presents a substantial opportunity for the functional coating market, primarily driven by the robust automotive and aerospace industries. The region is home to several leading manufacturers that focus on innovative coating solutions to improve surface properties, thereby enhancing product durability and performance. The demand for advanced coatings with functionalities such as anti-corrosion, anti-fogging, and anti-bacterial properties is steadily growing, making North America a notable in this market. Furthermore, stringent environmental regulations are pushing manufacturers towards eco-friendly coating solutions, driving further growth.

Europe

Europe is another significant market for functional coatings, characterized by a strong emphasis on sustainability and compliance with regulatory standards. The automotive sector in Europe is increasingly adopting advanced coatings to meet stringent performance and aesthetic requirements. The presence of established companies and a focus on research and development foster continuous innovation in coating technologies. Additionally, the rise in renewable energy applications, such as solar panels, is driving the demand for specialized coatings, thus reinforcing Europe's position in this competitive market landscape.

Latin America

While still developing, Latin America shows potential in the functional coating market with growth driven by the construction and automotive industries. The region is experiencing increased investments in infrastructure projects, which correlate with higher demands for protective coatings. However, factors such as economic instability and varying regulatory commitments limit faster growth. To enhance its position, the region will need to focus on promoting innovative coating technologies and improving distribution networks to cater to local demands.

Middle East & Africa

Middle East and Africa represent a nascent but emerging market in functional coatings, driven primarily by the oil and gas industry as well as construction projects. The unique climatic conditions in this region necessitate protective coatings capable of withstanding extreme heat and corrosive environments. However, challenges such as limited infrastructure and economic diversification may inhibit rapid growth. Investments in sustainable solutions and increasing urbanization can help bolster demand in the coming years, making it a to watch despite current constraints.

Functional Coating Market Competitive Landscape:

Prominent stakeholders in the worldwide functional coating sector, encompassing both manufacturers and technology innovators, propel advancements by offering sophisticated coating solutions applicable across diverse industries like automotive, aerospace, and electronics. Their collaborative ventures and research efforts notably improve product efficacy and sustainability, aligning with the evolving needs of the market.

The functional coating sector is significantly influenced by major corporations such as PPG Industries, AkzoNobel N.V., BASF SE, Sherwin-Williams Company, DuPont de Nemours, Inc., Dow Inc., Henkel AG & Co. KGaA, RPM International Inc., Jotun A/S, 3M Company, Eastman Chemical Company, Nippon Paint Holdings Co., Ltd., Axalta Coating Systems Ltd., Kansai Paint Co., Ltd., and Valspar Corporation. These organizations are leaders in innovating and supplying a wide range of functional coatings utilized in various fields, including automotive, aerospace, construction, and consumer products.

Global Functional Coating Market COVID-19 Impact and Market Status:

The Global Functional Coating market experienced substantial disruption due to the Covid-19 pandemic, which resulted in supply chain interruptions and changes in demand trends across multiple sectors.

The outbreak of the COVID-19 pandemic had a profound effect on the market for functional coatings, initially triggering significant disruptions in both manufacturing processes and supply chain logistics as a result of lockdowns and restrictions. Various sectors, such as automotive, construction, and electronics, experienced a dip in demand, leading to a temporary contraction in the market. Conversely, the ened focus on healthcare and the rising importance of hygiene and sanitation spurred an increased need for antimicrobial and protective coatings. Moreover, the shift towards remote work catalyzed a renewed interest in home improvement and safety measures, thereby benefiting the architectural coatings. As the situation improved, companies began to adapt by prioritizing product innovation and reinforcing their commitment to sustainability, reflecting the evolving consumer preference for environmentally friendly options. In summary, while the pandemic introduced immediate challenges, it also expedited trends that may result in potential growth for the functional coating market in the future.

Latest Trends and Innovation in The Global Functional Coating Market:

- In October 2022, PPG Industries completed the acquisition of A&E Coatings, a manufacturer of functional coatings, enhancing PPG's offerings in the protective and specialty coatings market.

- In July 2023, BASF announced the development of new bio-based functional coatings that utilize renewable raw materials, reflecting their commitment to sustainability in manufacturing processes.

- In September 2023, AkzoNobel launched a new line of high-performance functional coatings, including anti-microbial properties, designed specifically for the healthcare industry, improving hygiene and safety in medical environments.

- In April 2023, DuPont unveiled its innovative Waterborne Coating Solutions, aimed at reducing VOC emissions and improving efficiency in the automotive sector, positioning itself as a leader in eco-friendly coatings technology.

- In March 2023, Sherwin-Williams acquired the German company, Mäder Group, to enhance its product portfolio in functional coatings for the industrial market, particularly in anticorrosive applications.

- In June 2023, researchers at 3M introduced a new type of functional coating that improves the durability and performance of electronic devices, enabling better heat management and energy efficiency.

- In May 2023, Henkel AG announced a partnership with a leading tech firm to co-develop advanced functional coatings for additive manufacturing processes, ensuring better material properties and performance.

- In January 2023, Eastman Chemical Company revealed its plans to expand its functional coatings production capacity in response to increasing demand in the automotive and construction sectors.

Functional Coating Market Growth Factors:

The expansion of the Functional Coating Market is propelled by several factors, including the escalating need for sophisticated materials across sectors such as aerospace, automotive, and electronics, as well as a surge in environmental regulations encouraging the use of eco-friendly coatings.

The Functional Coating Market is witnessing significant expansion, fueled by various critical factors. A primary driver is the surge in demand for sophisticated materials across sectors such as automotive, electronics, and healthcare. Manufacturers are on the lookout for coatings that improve durability, offer corrosion resistance, and enhance visual appeal. Additionally, advancements in coating technologies, particularly in nanotechnology and sustainable formulations, are crucial for increasing efficiency and minimizing ecological footprints.

Growing consumer awareness regarding sustainability and energy efficiency is shaping preferences, resulting in a transition toward eco-friendly coatings that comply with regulatory requirements. Moreover, the booming construction industry in developing countries is elevating the demand for functional coatings that not only protect but also enhance the aesthetic aspects of buildings and infrastructure.

Innovations in smart coatings, which provide features like self-cleaning capabilities and anti-fog properties, are broadening application opportunities and drawing significant investment. Furthermore, the rebound in manufacturing and construction post-pandemic, along with a ened focus on safety and hygiene, is leading to greater acceptance of antimicrobial coatings. Together, these elements are propelling the Functional Coating Market forward, showcasing a promising outlook for the future.

Functional Coating Market Restaining Factors:

Significant inhibiting factors within the Functional Coating Market encompass the volatility of raw material costs and the imposition of rigorous environmental regulations.

The Functional Coating Market is confronted with various limiting factors that could influence its growth path. Among the primary challenges are the substantial production expenses linked to advanced coating technologies, which can restrict accessibility for smaller producers. Moreover, rigorous environmental regulations pertaining to volatile organic compounds (VOCs) and the demand for sustainable materials add complexity to the creation and market release of functional coatings. Dependence on certain raw materials might also introduce vulnerabilities within the supply chain, impacting availability and pricing consistency. Furthermore, the pace of technological advancements may exceed market readiness, creating a disconnect between innovation and practical implementation. Additionally, a lack of awareness and comprehension among end-users regarding the advantages and potential uses of functional coatings may impede market entry. Nevertheless, in spite of these hurdles, the rising demand for eco-friendly solutions and cutting-edge technologies offers considerable growth potential. As various sectors strive for better performance and sustainability, increased investment in research and development is likely to result in innovations that resolve existing challenges and propel the market forward. Furthermore, the progressive incorporation of smart technologies is anticipated to create new opportunities, promising a bright future for the functional coating sector.

Segments of the Functional Coating Market

By Function

• Anti-Corrosion

• Anti-Microbial

• Anti-Scratch

• Self-Cleaning

• Heat Insulation

By Material

• Polymers

• Ceramics

• Metals

• Graphene

• Carbon Nanotubes

By Coating Method

• Dip Coating

• Spray Coating

• Roller Coating

• Vapor Deposition

• Spin Coating

By Curing Process

• Thermal Curing

• UV Curing

• Electron Beam Curing

• Microwave Curing

• Laser Curing

By Application

• Automotive

• Medical

• Electronics

• Aerospace

• Marine

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America