Market Analysis and Insights:

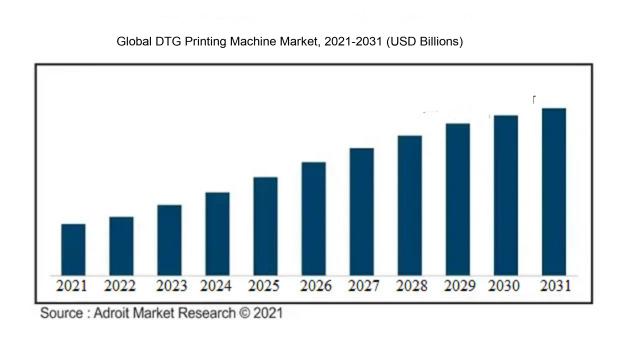

The market for Global DTG Printing Machine was estimated to be worth USD XX billion in 2021, and from 2021 to 2031, it is anticipated to grow at a CAGR of XX%, with an expected value of USD XX billion in 2031.

The market for DTG (Direct to Garment) printing machines is experiencing growth due to various important factors. An increasing desire for customized and unique apparel is a major driving force for this market. DTG printing machines offer a convenient way to personalize clothing with quick turnaround times, which appeals to both individuals and businesses seeking to create distinct garments. The expansion of the e-commerce sector and the proliferation of online custom clothing stores are also fueling the market's growth. DTG printing technology enables online businesses to provide customized clothing options to their customers with ease and flexibility.

Additionally, advancements in DTG printing technology, such as enhanced ink and printhead capabilities, are boosting market expansion by improving printing quality, speed, and efficiency. Furthermore, the rising awareness and adoption of environmentally friendly printing methods are increasing the demand for DTG printing machines, as they reduce the need for excessive dyeing and utilize water-based inks. Collectively, these driving forces are driving a notable increase in the demand for DTG printing machines and their market share.

DTG Printing Machine Market Scope:

| Metrics | Details |

| Base Year | 2023 |

| Historic Data | 2018-2022 |

| Forecast Period | 2024-2031 |

| Study Period | 2018-2031 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2031 | USD XX billion |

| Growth Rate | CAGR of XX% during 2021-2031 |

| Segment Covered | By Type, By Application, By Ink Type, By Region. |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Epson, Brother Industries, ROQ International, Kornit Digital, Anajet, Aeoon Technologies, M&R Printing Equipment, Ricoh, Mimaki Engineering, and Durst Group. |

Market Definition

Utilizing cutting-edge inkjet technology, a Direct-to-Garment (DTG) printer is a sophisticated tool that enables the direct printing of intricate, full-color designs onto various garments like t-shirts. This revolutionary method not only delivers high-resolution outputs but also streamlines the printing process significantly, reducing reliance on conventional screen printing techniques.

Direct-to-Garment (DTG) printing machines are integral to the printing sector for several compelling reasons. They facilitate the direct application of high-quality and intricate designs with vibrant colors onto fabrics, enhancing the visual appeal of garments. These machines offer remarkable versatility by accommodating various fabric types like cotton, polyester, and blends, enabling the printing of a wide array of apparel, ranging from t-shirts to hoodies and caps. Besides, DTG printing machines present a cost-efficient option due to their minimal setup requirements and low production costs, particularly beneficial for small-scale or personalized orders. The escalating preference for personalized products has spurred the demand for DTG printing machines, underscoring their significance in enabling businesses to satisfy customer preferences and maintain competitiveness in the industry. In essence, the value of DTG printing machines lies in their capacity to deliver top-notch, adaptable, cost-effective, and personalized printing solutions within the textile sector.

Key Market Segmentation:

Insights On Key Type

Single Pass

The Single Pass type is expected to dominate the Global DTG Printing Machine Market. This is primarily due to the efficiency and speed it offers in printing garments. Single Pass machines are designed to print directly onto fabric in a single motion, eliminating the need for multiple passes and reducing production time. This makes them highly sought after in the textile industry, where quick turnaround times and mass production capabilities are essential. Additionally, Single Pass machines generally require less maintenance and have lower operating costs compared to Multi-Pass machines, making them a preferred choice for many businesses.

Multi-Pass

The Multi-Pass type, while not expected to dominate the Global DTG Printing Machine Market, still holds a significant share. Multi-Pass machines are known for their ability to produce high-quality and detailed prints on various types of fabrics. These machines can make multiple passes over the garment, allowing for finer detail and better color saturation. They are commonly used in applications where print quality is of utmost importance, such as customization of high-end apparel, designer clothing, and art prints. Although Multi-Pass machines may be slower and require more maintenance compared to Single Pass machines, their focus on print quality makes them appealing to certain niche markets and industries.

Insights On Key Application

Consumer Clothing

Consumer clothing is expected to dominate the global DTG printing machine market. This application holds the largest share due to the increasing demand for personalized and customized clothing among consumers. DTG printing allows for high-quality and intricate designs on fabric, catering to the growing trend of individuality in fashion. With the advancement in technology and the availability of a wide range of vibrant colors and textures, DTG printing machines are becoming popular in the consumer clothing industry. Fashion brands, online clothing stores, and individual designers are adopting this technology to meet the rising consumer expectations for unique and personalized garments.

Industrial & Technical Textile

The industrial and technical textile application is anticipated to hold a significant share in the global DTG printing machine market. This part caters to various industries such as automotive, aerospace, healthcare, and architecture, where customized printing on textiles is required for specialized applications. DTG printing machines offer flexibility, precision, and cost-effectiveness in printing complex designs on industrial and technical textiles. With advancements in fabric technology and increasing demand for functional textiles with customized designs, the use of DTG printing machines in this part is expected to grow.

Soft Signage

Soft signage is another application that is likely to have a considerable presence in the global DTG printing machine market. Soft signage includes banners, flags, trade show graphics, and other promotional materials made from fabric. DTG printing machines provide an efficient and versatile solution for printing vibrant and eye-catching graphics on soft signage. This part is driven by the demand for visually appealing signage in retail, events, and advertising industries. The ability of DTG printers to reproduce intricate designs and deliver high-quality prints on various fabric substrates makes them a preferred choice in the soft signage part.

Sportswear

While consumer clothing, industrial & technical textile, and soft signage dominate the global DTG printing machine market, the sportswear application holds a smaller share. Sportswear manufacturers increasingly incorporate personalized prints and designs to meet the individual needs and preferences of athletes and fitness enthusiasts. While DTG printing machines offer customization options, the high-performance requirements of sportswear, such as breathability and moisture-wicking properties, often lead manufacturers to opt for other printing technologies like dye-sublimation. Therefore, although the sportswear part has potential growth, it is not expected to dominate the global DTG printing machine market as much as the other parts.

Insights On Key Ink Type

Pigment

The Pigment ink type is expected to dominate the Global DTG Printing Machine Market. Pigment inks are widely preferred for direct-to-garment printing due to their excellent color vibrancy, durability, and versatility. They offer superior wash fastness and resistance to fading, making them suitable for long-lasting designs on various fabric types. Additionally, Pigment inks provide a wider color gamut, allowing for vibrant and accurate color reproduction. With their growing popularity and superior performance characteristics, Pigment inks are projected to hold a significant share in the Global DTG Printing Machine Market.

Reactive Ink

Reactive inks are known for their high color yield and excellent print quality on natural fabrics, especially cotton. Although they have a specific application in the textile industry, reactive inks are not expected to dominate the Global DTG Printing Machine Market. Their usage is limited to specific fabric types, and their performance on synthetic blends is not as effective as other ink types. Therefore, while reactive inks remain important for certain textile applications, they may not command a significant market share in the DTG printing machine market.

Acid Ink

Similar to reactive inks, acid inks have their niche in the textile industry, particularly for printing on silk and wool fabrics. However, due to the limitations of their application and the availability of alternative ink types, acid inks are not anticipated to dominate the Global DTG Printing Machine Market. Their usage is relatively limited compared to other ink types, and they lack the versatility and broad compatibility required for a dominant market position.

Sublimation Ink

Sublimation inks are commonly used for garments made of polyester or polyester-coated substrates. While sublimation printing has its advantages in terms of color vibrancy and durability on polyester fabrics, it is not expected to dominate the Global DTG Printing Machine Market. The market for sublimation printing predominantly caters to specialized applications such as sportswear, promotional items, and polyester-based products. Hence, the limited scope and application of sublimation ink restrict its potential to dominate the overall DTG printing machine market.

Insights on Regional Analysis:

Europe

Europe is expected to dominate the Global DTG Printing Machine market. This region has a well-established textile industry and a strong emphasis on innovation and technology. Several countries in Europe, such as Germany, Italy, and the United Kingdom, are known for their high-quality textiles and fashion industry. Moreover, DTG printing machines offer various advantages such as the ability to print on demand, customization options, and eco-friendly operations, making them highly sought after in the European market. The presence of key players in the region and their continuous research and development efforts further contribute to the dominance of Europe in the Global DTG Printing Machine market.

North America

In North America, the Global DTG Printing Machine market is competitive and growing rapidly. The region has a strong demand for customized and personalized products, especially in the fashion and apparel industry. The United States, in particular, has a significant market share due to the presence of well-established fashion brands and a large consumer base. Additionally, the increasing trend of e-commerce and online retailing further drives the demand for DTG printing machines in North America. With the continuous technological advancements and the adoption of innovative printing technologies, North America is expected to be a key player in the Global DTG Printing Machine market.

Asia Pacific

The Asia Pacific region is also witnessing significant growth in the DTG Printing Machine market. This can be attributed to several factors, including the rise of the fashion and textile industry in countries like China, India, and Japan. These countries have a large population and a growing middle-class , leading to increased demand for customized and personalized products. Furthermore, the availability of low-cost labor and technological advancements in the region make it an attractive market for DTG printing machines. With the continuous development of infrastructure and the increasing adoption of digital printing technologies, Asia Pacific is poised to become a dominant player in the Global DTG Printing Machine market.

Latin America

Latin America is emerging as a potential market for DTG printing machines. The region has a growing fashion industry and a strong demand for personalized and customized products. Countries like Brazil, Mexico, and Argentina are witnessing an increase in the popularity of DTG printing machines due to their ability to offer vibrant and detailed prints on various textiles. Additionally, the rising trend of digital marketing and e-commerce in Latin America further boosts the demand for DTG printing machines. While the market is still in its early stages, Latin America has the potential to become a significant player in the Global DTG Printing Machine market.

Middle East & Africa

The Middle East & Africa region is gradually adopting DTG printing machines, driven by the increasing demand for custom-designed clothing, particularly in the luxury fashion . Countries like the United Arab Emirates and South Africa have a growing fashion industry and a high demand for personalized products. Moreover, the region's focus on sustainability and eco-friendly practices aligns with the advantages offered by DTG printing machines. Despite the relatively slower growth compared to other regions, Middle East & Africa has the potential to become a dominant player in the Global DTG Printing Machine market as the adoption of digital printing technologies continues to increase.

Company Profiles:

Prominent entities within the international DTG printing machine industry are tasked with producing and distributing state-of-the-art digital textile printing equipment to serve the rising need for superior and custom printing options in the textile sector. They play a pivotal part in driving innovation and providing effective and cutting-edge machinery to address the expanding requirements of the industry.

Prominent companies in the DTG printing machine industry consist of Epson, Brother Industries, ROQ International, Kornit Digital, Anajet, Aeoon Technologies, M&R Printing Equipment, Ricoh, Mimaki Engineering, and Durst Group. These companies are at the forefront of the market, showcasing pioneering technologies and solutions for direct-to-garment printing. Epson and Brother Industries are recognized for their diverse range of DTG printers, while ROQ International and Kornit Digital are notable for their high-speed and high-quality printing devices. Anajet and Aeoon Technologies also command a substantial market share with their advanced DTG printing solutions.

Additionally, M&R Printing Equipment, Ricoh, Mimaki Engineering, and Durst Group are significant players offering a variety of products to cater to the escalating demands in the DTG printing sector. As a collective, these key entities are propelling the progress and advancement of the DTG printing machine .

COVID-19 Impact and Market Status:

The Global DTG Printing Machine market has experienced a decrease as a result of the Covid-19 pandemic, primarily caused by supply chain disruptions and diminished consumer expenditure.

The global economy has been significantly affected by the COVID-19 pandemic, which has also impacted the Direct-to-Garment (DTG) printing machine market. Government-enforced lockdowns have led to the temporary closure of many businesses, particularly textile and apparel manufacturing units that are major users of DTG printing machines. The decrease in consumer spending and the emphasis on essential goods have resulted in a reduced interest in customized and printed clothing, causing businesses to delay or cancel investments in printing equipment. This, in turn, has slowed down the DTG printing machine market. Furthermore, disruptions in the supply chain due to factory shutdowns and transportation constraints have further impeded market growth. However, with the gradual reopening of economies and the growing demand for personalized products, the DTG printing machine market is projected to recover. Manufacturers are also concentrating on innovation, including the creation of environmentally friendly and cost-efficient printing machines, to regain market momentum. While the initial impact of COVID-19 on the DTG printing machine market has been adverse, the long-term outlook is promising as the industry adjusts to changing market dynamics.

Latest Trends and Innovation:

- In 2019, Epson, a leading manufacturer of printing equipment, introduced the SureColor F3070, a high-speed direct-to-garment (DTG) printing machine, capable of producing full-color prints on garments at industry-leading speeds.

- In March 2020, Brother International Corporation, a prominent player in the printing market, announced the acquisition of Domino Printing Sciences, a leading digital inkjet printing solutions provider. This transaction aimed to strengthen Brother's portfolio of industrial printing technologies, including DTG printing.

- Kornit Digital, a reliable supplier of digital textile printing solutions, unveiled the Kornit NeoPoly Technology in July 2020. This innovation allowed for high-quality and sustainable printing on polyester fabrics, expanding the capabilities of DTG printing in the market.

- Ricoh Company Ltd., a multinational imaging and electronics company, released the Ri 2000 and Ri 1000 direct-to-garment printers in 2020. These printers offered advanced features such as white ink opacity and eco-friendly performance, catering to the increasing demand for sustainable printing solutions.

- ColDesi Inc., a distributor of printing equipment and supplies, partnered with Coldesi DTG, a manufacturer of DTG printers, in January 2021. This collaboration aimed to broaden the reach of Coldesi's DTG products and enhance the distribution network for efficient market penetration.

- AnaJet, a subsidiary of Ricoh Company Ltd., made advancements in DTG printing technology with the introduction of the Ricoh Ri 2000e and AnaRIP software. This technology enabled fast and accurate printing on a wide range of fabrics while offering user-friendly control and workflow capabilities.

Significant Growth Factors:

The expansion of the DTG printing machine industry can be linked to several factors including the rising consumer preference for personalized and customized clothing, advancements in printing technology, and the surge in the use of online retail platforms.

The substantial expansion of the DTG printing machine market is propelled by a multitude of factors. Foremost among them is the surging desire for personalized apparel and textile items, which is driving the adoption of DTG printing machines. These machines excel in high-resolution printing and the printing of intricate designs, making them particularly coveted in the fashion sector. Furthermore, the burgeoning e-commerce landscape has played a pivotal role in propelling the growth of the DTG printing machine market. As online shopping platforms proliferate, the need for swift and efficient on-demand printing of bespoke designs on clothing has escalated. DTG printing machines adeptly meet this demand by ensuring rapid turnaround times and minimizing the requirement for large inventories. In addition, technological advancements have led to the creation of more cost-efficient and productive DTG printing machines. The deployment of eco-friendly, water-based inks has effectively tackled concerns regarding environmental sustainability, further incentivizing the uptake of these machines. Additionally, the escalating consumer consciousness regarding sustainable and ethical fashion practices has emerged as a driving force behind the expansion of the DTG printing machine market. These machines offer the flexibility to print on organic and recycled materials, resonating with the preferences of environmentally mindful consumers. Moreover, the proliferation of small and medium-sized enterprises in the fashion and promotional products sector has generated a robust market for DTG printing machines. These enterprises often necessitate high-quality printing in low volumes, a demand that DTG printing machines adeptly meet.

Restraining Factors:

An inhibiting factor within the Direct-to-Garment (DTG) printing machine sector pertains to the considerable upfront investment required for the acquisition of such equipment, thereby constraining its uptake among enterprises operating on a smaller scale.

The market for Direct to Garment (DTG) printing machines has experienced notable growth in recent times owing to its capacity to directly print high-quality graphics onto fabric. Nevertheless, there exist various factors that may impede the expansion of this market. Primarily, the substantial cost associated with DTG printing machines stands out as a significant obstacle. These machines entail high initial procurement and maintenance expenses, thereby restricting their uptake among smaller enterprises and individuals. Additionally, the limited variety of materials that can be printed poses a constraint, with DTG printing predominantly utilized on cotton-based fabrics, limiting its utility in sectors involving synthetic textiles. The slower printing pace of DTG machines in comparison to conventional screen printing methods can also serve as a hindrance to high-volume production. Moreover, the intricate nature of operating and sustaining these machines necessitates skilled technicians, resulting in supplementary costs. Lastly, fierce competition from alternative printing techniques like screen printing, sublimation, and heat transfer, each offering distinct benefits, has created a challenging landscape for the DTG printing machine market. Despite these obstacles, the market for DTG printing machines is anticipated to observe favorable growth in the future. With ongoing technological advancements enhancing printing speeds, broadening the spectrum of printable materials, and reducing expenses, the impediments faced by the market are poised to diminish. Furthermore, the escalating demand for customized and tailor-made apparel is expected to fuel the adoption of DTG printing machines, propelling the market towards fresh opportunities and advancement.

Key Segments of the DTG Printing Machine Market

Type Overview

• Single Pass

• Multi-Pass

Application Overview

• Consumer Clothing

• Industrial & Technical Textile

• Soft Signage

• Sportswear

Ink Type Overview

• Sublimation ink

• Reactive ink

• Acid ink

• Pigment ink

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America