Market Analysis and Insights:

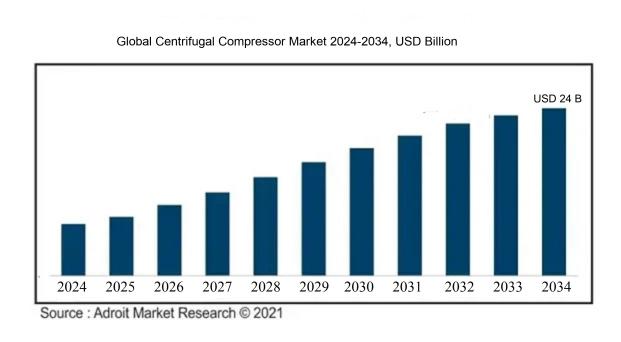

The market for Global Centrifugal Compressor was estimated to be worth USD 16 billion in 2024, and from 2024 to 2034, it is anticipated to grow at a CAGR of 5%, with an expected value of USD 24 billion in 2034.

The centrifugal compressor market is largely influenced by several pivotal factors, notably the ened demand for efficient industrial operations and the expanding application of these compressors across various industries, including oil and gas, chemicals, and manufacturing. The expansion of the global manufacturing landscape, especially in developing nations, necessitates enhanced air and gas management capabilities offered by centrifugal compressors. Moreover, advancements in technology designed to improve energy efficiency and performance serve to further stimulate market development, as businesses aim to reduce operational costs while minimizing their environmental footprint. The transition towards sustainable and renewable energy sources is also bolstering the need for centrifugal compressors in processes like biogas purification and hydrogen generation. Additionally, stringent regulations aimed at curbing emissions and reducing energy usage propel industries to adopt innovative compressor solutions, reinforcing the growth trajectory of the market in the years to come.

Centrifugal Compressor Market Scope :

| Metrics | Details |

| Base Year | 2024 |

| Historic Data | 2020-2023 |

| Forecast Period | 2024-2034 |

| Study Period | 2023-2034 |

| Forecast Unit | Value (USD) |

| Revenue forecast in 2034 | USD 24 billion |

| Growth Rate | CAGR of 5% during 2024-2034 |

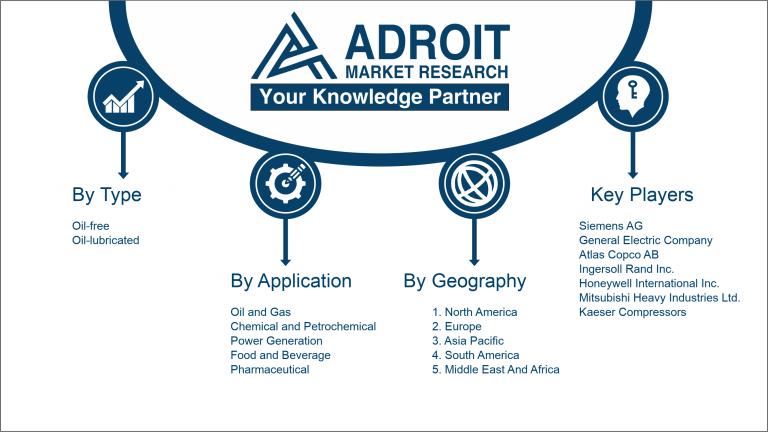

| Segment Covered | By Type, By Stage Configuration, By Application, By End-user, Regions |

| Regions Covered | North America, Europe, Asia Pacific, South America, Middle East and Africa |

| Key Players Profiled | Siemens AG, General Electric Company, Atlas Copco AB, Ingersoll Rand Inc., Honeywell International Inc., Mitsubishi Heavy Industries Ltd., Kaeser Compressors, Gardner Denver Holdings, Inc., Elliott Group, Ltd., Boge Compressors, and Ansaldo Energia S.p.A. |

Market Definition

A centrifugal compressor is a device designed to elevate the pressure of a gas by transforming kinetic energy, produced by the swift spinning of an impeller, into potential energy. This type of compressor is widely utilized in an array of settings, such as refrigeration systems, air conditioning units, and gas processing operations.

Centrifugal compressors are vital components across multiple sectors such as energy production, petroleum, and aviation, as they effectively enhance gas pressure for diverse uses. Their compact architecture, combined with the capability to manage large gas volumes and minimal maintenance needs, renders them suitable for industrial and commercial applications alike. The aerodynamic structure facilitates seamless gas movement, which aids in energy conservation and dependable operation. Furthermore, these compressors are essential in applications like refrigeration, heating, ventilation, air conditioning, and gas distribution, where stable and dependable pressure is crucial for maintaining performance and ensuring operational safety.

Key Market Segmentation:

Insights On Key Type

Oil-free

Oil-free centrifugal compressors are expected to dominate the global centrifugal compressor market due to their growing importance in applications where purity is paramount, such as food processing, pharmaceuticals, and electronics. Increasing regulatory standards and consumer demand for clean and oil-free air have driven manufacturers to adopt advanced technologies focused on oil-free designs. Additionally, the energy efficiency of these compressors lowers operational costs in the long run, making them a preferred choice for many industries. The increasing focus on sustainability and reducing carbon footprints further underscores the potential growth of oil-free centrifugal compressors, affirming their leading position in the market.

Oil-lubricated

Oil-lubricated centrifugal compressors cater to industries where oil is acceptable for operational efficiency. These compressors typically offer higher performance and durability, making them suitable for high-demand applications, such as power generation and heavy manufacturing. The lubrication helps reduce friction, leading to fewer mechanical failures and extending the equipment's lifespan. However, their rise is challenged by the tightening regulations on emissions and need for oil disposal, impacting their overall market presence. Despite this, the reliability and efficacy in certain applications keep oil-lubricated systems relevant.

Insights On Key Stage Configuration

Multi-stage Centrifugal Compressors

Multi-stage centrifugal compressors are expected to dominate the Global Centrifugal Compressor Market due to their ability to manage high-pressure applications efficiently. They are increasingly being used across a variety of industries, including oil and gas, chemical processing, and power generation, owing to their superior performance in gas compression over single-stage variants. These compressors can offer better efficiency, increased pressure ratios, and improved reliability, which aligns with the growing demand for energy-efficient and cost-effective solutions in high-capacity systems. Companies are focusing on technological advancements and innovations in multi-stage designs, thus further solidifying their dominance in the market.

Single-stage Centrifugal Compressors

Single-stage centrifugal compressors find their primary appeal in low-pressure applications and sectors where simplicity and cost-effectiveness are crucial. They offer less complexity in design, making them easier to maintain and operate compared to multi-stage options. Furthermore, single-stage compressors are widely used in smaller systems, including HVAC and light industrial applications, where the demands on pressure delivery are not as high. Though they currently have a narrower operational scope, the demand in specific industries continues to ensure their relevance in the market.

Insights On Key Application

Chemical and Petrochemical

The chemical and petrochemical industry is expected to dominate the Global Centrifugal Compressor Market due to its extensive application in various processes such as gas compression, dehydration, and chemical vapors, which require efficient compression solutions. The growing demand for chemicals and refined products, driven by industrial sectors and urbanization, has increased the need for reliable and efficient compressors. Additionally, as industries evolve and expand their operations, they require sophisticated technology to maintain high output capacities while minimizing energy consumption. Overall, the agility of centrifugal compressors in handling diverse applications positions them as critical for the future growth of the chemical and petrochemical industry.

Oil and Gas

The oil and gas sector remains a significant player in the centrifugal compressor market. These machines are integral for enhancing gas extraction processes by efficiently compressing natural gas and optimizing transportation through pipelines. Recent advancements in recovery techniques and increasing global energy demands further drive the requirement for high-performance compressors in this domain. Additionally, the industry's striving for more sustainable and efficient practices has opened the door for technological innovations, making centrifugal compressors even more essential for operational efficiency and energy savings.

Power Generation

Centrifugal compressors are extensively utilized within the power generation sector, especially in gas turbine systems, where they significantly contribute to improving combustion efficiency and overall energy output. As the world shifts towards cleaner energy production, there is an increased focus on combined cycle power plants, which require high-capacity compressors for optimal performance. Additionally, the demand for renewable energy sources, such as biofuels and hydrogen production, is also boosting interest in high-efficiency centrifugal compressors to support these evolving power strategies.

Food and Beverage

In the food and beverage industry, centrifugal compressors play a pivotal role in various processes, including the refrigeration of perishable goods and the processing of food products. The rising consumer demand for fresh and processed foods necessitates the use of high-efficiency compressors for temperature control and rapid processing. Moreover, stringent regulations around food safety and quality assurance drive the need for reliable technology that can effectively manage the various stages of food production, making centrifugal compressors an essential component in this sector.

Pharmaceutical

The pharmaceutical industry also utilizes centrifugal compressors to facilitate various applications, such as the production of active pharmaceutical ingredients (APIs) and in the provision of clean compressed air for critical processes. The growing focus on research and development in pharmaceuticals demands highly dependable and efficient equipment that can maintain strict control over environmental parameters. In addition, the trend towards biopharmaceuticals and the increasing complexity of drug formulations further necessitates the incorporation of advanced compression solutions to ensure precise and optimal production characteristics.

Insights On Key End-user

Energy

The energy sector is anticipated to dominate the Global Centrifugal Compressor Market due to the increasing demand for energy efficiency and the drive towards sustainable energy solutions. With the rise in renewable energy projects and natural gas extraction, centrifugal compressors play a crucial role in gas processing and transportation. Moreover, the ongoing advancements in technology and the need for optimizing energy systems further enhance the application of centrifugal compressors in this sector. The need for improved performance and reliable operations in energy production and transmission establishes this category as the leading user of centrifugal compressors worldwide.

Manufacturing

The manufacturing industry is a significant user of centrifugal compressors due to its requirements for efficient air and gas handling in various processes. These compressors are widely adopted in applications such as pneumatic conveying, material handling, and the production of chemicals. The demand for high-performance equipment and technological innovations in manufacturing processes drive the need for advanced centrifugal compressors. Furthermore, as manufacturers focus on increasing productivity and reducing operational costs, the adoption of centrifugal compressors continues to grow, making it a key player in the market.

Healthcare

The healthcare sector also utilizes centrifugal compressors, primarily for applications related to medical gas supply and air compression in hospitals and laboratories. These compressors maintain consistent pressure and flow rates required for equipment such as ventilators and anesthesia machines. As the healthcare sector expands with ongoing technological advancements and ened awareness surrounding medical infrastructure, the reliance on efficient and reliable centrifugal compressors is expected to increase. Additionally, the growing global population and rising healthcare demands will keep fueling the need for these compressors in the coming years.

Food and Beverage

In the food and beverage industry, centrifugal compressors are critical for applications involving refrigeration, air supply, and processing. These compressors help maintain optimal temperatures and conditions for food storage and processing, ensuring product safety and quality. With the increasing emphasis on food preservation and hygiene, centrifugal compressors are becoming increasingly important to the sector. As innovation in food processing technology progresses, the demand for reliable and energy-efficient compressors within the food and beverage industry is anticipated to rise, supporting its steady growth in the market.

Others

The "Others" category encompasses a variety of industries that utilize centrifugal compressors, including transportation, pharmaceuticals, and wastewater management. These compressors are essential for applications requiring efficient flow of gases and liquids. As different sectors explore energy-efficient solutions, the use of centrifugal compressors is expanding across diverse applications. However, while this category captures a broad range of uses, its overall share remains smaller compared to the more established sectors like energy and manufacturing. The growth in niche applications and technological advancements may, however, present future opportunities for growth.

Insights on Regional Analysis:

Asia Pacific

Asia Pacific is expected to dominate the Global Centrifugal Compressor market significantly over the coming years. This dominance is primarily driven by rapid industrialization, the expanding manufacturing sector, and the high demand for energy-efficient solutions across countries like China and India. The region is also experiencing considerable investment in infrastructure development, particularly in oil and gas, chemicals, and power generation industries. Furthermore, innovation in product offerings, such as advancements in technology and performance, is fostering strong growth. With these factors combined, Asia Pacific is well-positioned to maintain its leadership in the centrifugal compressor market.

North America

North America holds a strong position in the Global Centrifugal Compressor market due to its advanced infrastructure and mature industries. The presence of major oil and gas companies, along with stringent environmental regulations, drives demand for innovative, energy-efficient compressors. Additionally, technological advancements and the need for enhanced operational efficiencies contribute to growth in this region. However, the market's maturity leads to slower growth rates compared to emerging regions like Asia Pacific.

Europe

Europe showcases a robust market for centrifugal compressors, primarily fueled by the automotive, aerospace, and chemical industries. Stringent regulations focusing on emissions and energy efficiency are prompting companies to invest in state-of-the-art compressor technologies. The increasing shift towards renewable energy sources further encourages the adoption of centrifugal compressors, especially for energy recovery applications. Despite its growth potential, Europe faces competition from more rapidly developing regions.

Latin America

Latin America is experiencing a gradual increase in centrifugal compressor demand primarily due to infrastructure development and investments in energy projects. Key sectors such as mining, oil and gas, and water treatment drive the market, although political and economic instability may hinder consistent growth. The region's focus on renewable energy is also beginning to create opportunities for advanced compressor technologies. Overall, while growth is present, it is slower compared to Asia Pacific and North America.

Middle East & Africa

The Middle East & Africa region exhibits a niche but significant demand for centrifugal compressors, driven largely by the oil and gas sector. With the region being a major player in global oil production, there is a continual need for reliable and efficient compressors for various applications. Challenges such as political instability and infrastructure inadequacies may restrict faster market growth. However, ongoing investments in expanding oil and gas exploration activities may provide opportunities for growth in centrifugal compressor technology in the long run.

Company Profiles:

Prominent figures within the Global Centrifugal Compressor market, including leading manufacturers and suppliers, play a crucial role in fostering innovation, advancing technology, and increasing production capabilities to fulfill a wide range of industrial requirements. Their impact extends to shaping market trends through strategic alliances and establishing benchmarks for efficiency and environmental responsibility.

Prominent entities in the centrifugal compressor industry encompass Siemens AG, General Electric Company, Atlas Copco AB, Ingersoll Rand Inc., Honeywell International Inc., Mitsubishi Heavy Industries Ltd., Kaeser Compressors, Gardner Denver Holdings, Inc., Elliott Group, Ltd., Boge Compressors, and Ansaldo Energia S.p.A. Furthermore, the market also sees significant involvement from firms such as Clark Reliance Corporation, MAN Energy Solutions, Flender GmbH, and Rolls-Royce Holdings plc. Other important contributors include Aker Solutions, Nissan Motor Co. Ltd., and KSB SE & Co. KGaA, all of which play essential roles in driving innovation and progress within the centrifugal compressor domain.

COVID-19 Impact and Market Status:

The Covid-19 pandemic profoundly impacted the worldwide centrifugal compressor industry, hampering production activities and leading to decreased demand in multiple sectors including oil and gas, automotive, and HVAC.

The COVID-19 outbreak had a profound impact on the centrifugal compressor sector, disrupting multiple industries. Initially, stringent lockdown measures and restrictions hindered manufacturing and disrupted supply chains, causing delays and elevating production costs. As a result, demand for centrifugal compressors saw a downturn, particularly within the oil and gas, automotive, and HVAC sectors, with numerous projects being deferred or scrapped altogether. However, as economies began to stabilize and industries adjusted to new operational realities, a slow recovery in demand became evident. The increasing emphasis on renewable energy and sustainability prompted greater investments in cutting-edge compressor technologies, particularly in power generation and industrial applications. Furthermore, the post-pandemic focus on enhancing energy efficiency spurred the innovation of advanced centrifugal compressor solutions. In summary, while the pandemic introduced considerable obstacles, it also paved the way for growth through technological innovation and a shift towards more sustainable practices, resulting in a more optimistic market outlook.

Latest Trends and Innovation:

- In January 2023, Siemens Energy announced the acquisition of the US-based company, Dresser-Rand, to enhance its portfolio in sustainable propulsion and power generation technologies, specifically focusing on centrifugal compressors for the oil and gas sector.

- In March 2023, Atlas Copco revealed its new line of centrifugal compressors, featuring advanced energy recovery options, which are aimed at improving operational efficiency in industrial applications.

- In June 2023, Dallas-based Ingersoll Rand completed its acquisition of the Swedish company, Ceres Media, to strengthen its position in the centrifugal compressor market for energy-efficient solutions targeted at the semiconductor industry.

- In August 2023, Honeywell launched its next-generation centrifugal compressor technology designed for HVAC applications, which utilizes artificial intelligence for enhanced performance and predictive maintenance capabilities.

- In September 2023, Sulzer announced a partnership with the Norwegian company, Aker Solutions, to co-develop next-generation centrifugal compressors specifically tailored for the renewable energy sector, focusing on hydrogen production and carbon capture technologies.

- In October 2023, GE Aviation unveiled a new centrifugal compressor model that integrates digital twin technology, aimed at reducing weight and increasing fuel efficiency for its aerospace applications.

- In November 2023, Mitsubishi Heavy Industries announced a strategic alliance with the Italian company, Nuovo Pignone, to collaborate on R&D initiatives aimed at advancing compressor technologies for industrial and energy applications.

Significant Growth Factors:

The centrifugal compressor market is experiencing growth driven by several key factors, including a ened need for energy-efficient machinery, a surge in industrial activities, and technological innovations that enhance performance capabilities.

The centrifugal compressor sector is witnessing robust expansion, fueled by a variety of influences. A key driver is the increasing integration in diverse industries such as oil and gas, power generation, and HVAC systems. The demand for both energy-efficient and sustainable compressing technologies is spurring advancements in innovation, resulting in the creation of sophisticated centrifugal compressors that optimize performance and decrease operational expenses. Additionally, the rapid industrialization and urban growth in developing regions are amplifying the need for dependable air and gas management systems. Stricter regulations aimed at enhancing energy efficiency and minimizing emissions further encourage market advancement as businesses pursue solutions that comply with these standards. Furthermore, breakthroughs in materials science enable the production of lightweight, durable compressor components, enhancing their reliability and lifespan. The rising emphasis on renewable energy also significantly influences this sector, as centrifugal compressors find increased application in biogas and biomass projects. The movement towards automation and digital transformation across various industries is leading to the deployment of more intelligent compressors equipped with integrated monitoring capabilities, thus improving operational effectiveness. Altogether, these elements are deeply impacting the upward trajectory of the centrifugal compressor market, fostering a positive forecast for the future.

Restraining Factors:

The primary challenges hindering the centrifugal compressor market consist of substantial upfront expenses and the intricate technical requirements related to maintenance and operational procedures.

The centrifugal compressor industry encounters various constraints that could impede its expansion. Firstly, the substantial upfront investment required for these compressors may discourage smaller enterprises or those located in developing regions from embracing this technology. Moreover, the intricate nature of installation and maintenance demands skilled professionals, who may not be easily accessible in some areas, ultimately leading to higher operational expenses. Stringent environmental regulations and a ened focus on energy efficiency may also create obstacles, as conventional centrifugal compressors tend to be less energy-efficient compared to other options. Additionally, fluctuations in the prices of raw materials can influence manufacturing expenses and, in turn, pricing structures. The competitive threat from rotary compressor systems, which often feature simpler configurations and reduced operating costs, could further restrict market growth. Finally, variable demand from major end-user sectors such as oil and gas, automotive, and chemicals can affect the need for centrifugal compressors. Nonetheless, despite these hurdles, the market shows promising potential for growth through innovations in energy efficiency and advancements in digital technologies, positioning it as a robust sector capable of adapting to evolving industrial demands.

Key Segments of the Centrifugal Compressor Market

By Type

• Oil-free

• Oil-lubricated

By Stage Configuration

• Single-stage Centrifugal Compressors

• Multi-stage Centrifugal Compressors

By Application

• Oil and Gas

• Chemical and Petrochemical

• Power Generation

• Food and Beverage

• Pharmaceutical

By End-user

• Manufacturing

• Energy

• Healthcare

• Food and Beverage

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America