Blow Molded Plastics Market Analysis and Insights:

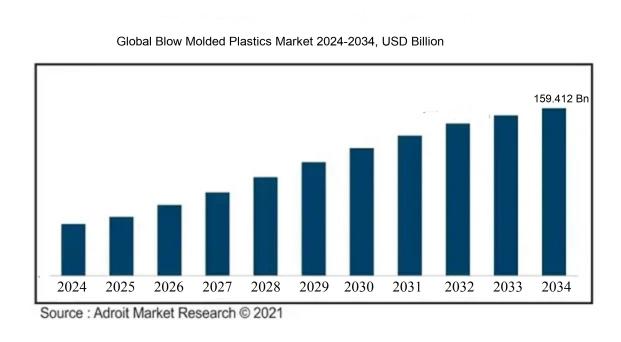

The size of the worldwide blow-molded plastics market was USD 96.15 billion in 2024, increased to USD 103.05 billion in 2025, and is projected to reach around USD 159.412 billion by 2034, with a compound annual growth rate (CAGR) of 6.3% between 2024 and 2034.

The Blow Molded Plastics Market experiences significant growth due to the increasing requirement for lightweight, robust, and adaptable packaging across multiple sectors, including food and beverage, pharmaceuticals, and consumer products. The rise in sustainable practices has also propelled the use of recycled blow molded plastics, appealing to environmentally conscious consumers. Advancements in blow molding techniques are improving manufacturing efficiency and design options, further fueling market development. The growth of e-commerce, along with the need for efficient product protection during transportation, is driving demand for innovative packaging solutions. Additionally, the automotive industry’s embrace of blow molded parts for lightweight construction aids in enhancing fuel efficiency, contributing to the sector's growth. These elements, along with a ened emphasis on customization and convenience, underscore the diverse potential for expansion in the blow molded plastics market, addressing various consumer preferences and industry needs.

Blow Molded Plastics Market Definition

Blow molding is a technique used to produce hollow plastic items by expanding molten plastic inside a mold to achieve desired forms. This method is frequently employed to manufacture a range of products, including containers, bottles, and sizable objects using materials such as polyethylene and polypropylene.

Blow molding of plastics is essential across numerous sectors, owing to its distinctive attributes of adaptability, low weight, and economical production. This technique enables the creation of intricate forms and sizable hollow products, including containers, bottles, and components for vehicles, while generating minimal material waste. The capacity to tailor designs and use various types of plastics significantly broadens their use in fields such as packaging, consumer items, and industrial settings. Moreover, the strength and environmental resistance of blow molded plastics render them suitable for a range of applications, both inside and outdoors, fostering advancements and sustainability in material usage.

Blow Molded Plastics Market Segmental Analysis:

Insights On Technology

Injection Blow Molding

Injection Blow Molding is expected to dominate the Global Blow Molded Plastics market due to its versatility and efficiency in producing complex shapes with high precision. This technology is preferred in the manufacturing of small to medium-sized containers, primarily in the pharmaceutical, food, and consumer goods industries, where product integrity and design flexibility are crucial. The low cycle times compared to other methods contribute to its cost-effectiveness and ability to meet high volume demands, driving its adoption across various applications. Furthermore, advancements in technology continue to enhance the capabilities of Injection Blow Molding, making it suitable for a growing range of materials and applications.

Extrusion Blow Molding

Extrusion Blow Molding is primarily utilized for larger containers and bottles, such as those used for industrial, chemical, and agricultural products. This technique allows for the production of hollow items with uniform wall thickness and is advantageous due to its relatively low tooling costs. While it provides high production rates, its limitation lies in producing more complex geometries. The growth of consumer products requiring lightweight and cost-efficient packaging solutions has propelled its use in diverse sectors, giving it a solid presence in the market.

Stretch Blow Molding

Stretch Blow Molding is chiefly employed in producing high-strength plastic bottles, particularly PET bottles for beverages and food products. This method enhances the mechanical properties of the plastic while providing a superior aesthetic appeal. The increasing demand for lightweight and recyclable packaging in industries like bottled water and soft drinks has bolstered its market penetration. Furthermore, innovations like reheat stretch blow molding are continually improving product performance, positioning this technology favorably in the competitive landscape despite facing challenges from the rising usage of alternative materials.

Compound Blow Molding

Compound Blow Molding is less acknowledged compared to other techniques but plays a crucial role in manufacturing specialized products with dual materials. This method allows for the combination of different plastics, which can enhance barrier properties and functionality. Although it has a niche market, it is essential in the production of parts requiring specific characteristics, such as improved chemical resistance or aesthetics. The growing trend of customization in packaging and automotive components may enable Compound Blow Molding to carve out a stronger foothold in certain industry s, focusing on unique performance requirements.

Insights On Product

Polyethylene

Based on recent research and market trends, Polyethylene is expected to dominate the Global Blow Molded Plastics Market. Its widespread applicability and versatility make it an optimal choice across multiple industries, including packaging, automotive, and consumer goods. Polyethylene exhibits excellent durability and a range of mechanical properties, making it suitable for blow molding applications. Additionally, the growing demand for lightweight and cost-effective materials, especially in the packaging sector, further enhances Polyethylene's market presence. The ease of processing and recycling capabilities of Polyethylene also contribute to its leading position, aligning with sustainability efforts in various industries.

Polypropylene

Polypropylene is renowned for its excellent chemical resistance and high melting point, making it a strong candidate for applications in automotive and industrial components. It possesses good tensile strength and low density, which results in significant weight savings in molded products. Its utility in consumer goods packaging is also notable due to its clarity and impact resistance. However, while it shows promise, it does not match the widespread demand that Polyethylene garners in the blow molding.

Acrylonitrile Butadiene Styrene

Acrylonitrile Butadiene Styrene (ABS) is favored for its robust impact resistance and aesthetic flexibility. Its applications are largely concentrated in products requiring high strength and durability, such as containers and automotive parts. While it holds a vital role in niche markets, its cost and processing complexity make it less versatile compared to Polyethylene, limiting its overall market share in blow molding applications.

Polystyrene

Polystyrene is commonly used for its low cost and excellent thermal insulation properties. Typically applied in packaging, disposable cutlery, and containers, it excels in applications where lightweight and disposable products are essential. Its limited strength compared to other plastics, however, restricts its utility in heavy-duty applications, thereby diminishing its competitiveness in the broader blow molding market dominated by Polyethylene.

Polyvinyl Chloride

Polyvinyl Chloride (PVC) offers excellent durability and is highly resistant to environmental degradation. Its applications range from pipes and fittings to various types of packaging. While it is favored is specific industrial applications, its processing requirements and environmental concerns offset its usage in the blow molding market significantly when compared to Polyethylene.

Polyethylene Terephthalate

Polyethylene Terephthalate (PET) is primarily engaged in the production of bottles and containers, especially in the beverage industry. It provides excellent barrier properties against gases and moisture, elongating product shelf life. However, its complexity in processing and higher cost relative to alternatives like Polyethylene limit its broader adoption in the blow molding, making it less competitive overall.

Polyamide (Polyamide 6, Polyamide 66)

Polyamide, including types like Polyamide 6 and Polyamide 66, is recognized for its strength, chemical resistance, and thermal stability. These properties make it suitable for applications in automotive and industrial parts, where durability is crucial. However, the higher cost and complexity of processing compared to Polyethylene make Polyamide less prevalent in the blow molding market, resulting in a smaller market presence.

Insights On Application

Packaging

The Packaging application is expected to dominate the Global Blow Molded Plastics Market due to the increasing demand for lightweight, durable, and sustainable packaging solutions across various industries. The rise in e-commerce and the need for protective packaging to minimize product damage during transit have driven the growth in this sector. Moreover, innovations in sustainable materials and designs are becoming more critical as companies and consumers shift towards environmentally friendly practices. As an essential component of the consumer goods and food & beverage sectors, the packaging application maintains a significant market share and shows a strong growth trajectory, positioning it as the leader in the blow molded plastics sector.

Consumables & Electronics

The Consumables & Electronics sector has shown considerable growth, primarily driven by the increasing production of electronic goods and consumer products. Manufacturers utilize blow molded plastics for creating lightweight and durable components that protect sensitive electronic items. With continuous advancements in technology and a rise in disposable electronics, this category will remain influential, catering to a higher demand for efficient packaging and protective cushioning.

Automotive & Transport

The Automotive & Transport industry is progressively adopting blow molded plastics for manufacturing various components due to their benefits, such as weight reduction and cost efficiency. As automotive companies strive for better fuel efficiency and lower emissions, lighter materials are becoming essential. The use of blow molded plastics in fuel tanks, bumpers, and other automotive parts is projected to grow as electric vehicles and hybrid models gain popularity, leading to innovations in the transport sector.

Building & Construction

In the Building & Construction sector, blow molded plastics are gaining traction for applications such as insulation, plumbing components, and storage solutions. These materials are appreciated for their resistance to moisture and durability, crucial attributes for construction projects. The rising trends in modern architecture and sustainable construction practices are propelling demand in this, as more builders adopt innovative materials that enhance energy efficiency and reduce waste.

Medical

The Medical application of blow molded plastics is gaining attention due to the increasing need for disposable medical equipment and packaging. The rise in global health awareness and the prevalence of healthcare-associated infections have led to a higher demand for sterilized and cost-effective medical supplies. With blow molded plastics offering customizable designs and high safety standards, this field is likely to see continued growth as hospitals and clinics seek efficient and reliable solutions for their needs.

Others

The Others encompasses various niche applications that may include toys, furniture, and various consumer goods. While this category does not dominate the overall market, it shows promise with the trend towards personalized and lightweight products. Innovations and customization in design are driving small-scale growth, but this area remains overshadowed by larger applications like Packaging and Automotive, reflecting diverse consumer preferences across multiple industries.

Global Blow Molded Plastics Market Regional Insights:

Asia Pacific

Asia Pacific is expected to dominate the Global Blow Molded Plastics market due to rapid industrial growth, increasing demand from end-use industries like automotive, consumer goods, and packaging, and a strong manufacturing base. Countries like China and India are the leading players, fueled by urbanization, rising disposable incomes, and a burgeoning population. Additionally, the region’s lower labor costs and increasing foreign investments in manufacturing further enhance the competitiveness of blow molded plastics production. The region's robust supply chain and development of eco-friendly materials also act as pivotal drivers, ensuring it retains a significant share of the global market.

North America

North America is a significant player in the Global Blow Molded Plastics market, driven primarily by technological advancements and high demand from the automotive and consumer goods sectors. The U.S. leads in producing specialized blow molded plastics for packaging, including containers and bottles. Additionally, the region benefits from stringent regulations that ensure product quality, encouraging the use of advanced blow molding technologies. Increased focus on sustainability also promotes research and the development of bio-based and recyclable products in this mature market.

Europe

Europe’s market for blow molded plastics remains strong due to the high emphasis on regulatory standards and environmental sustainability. Countries like Germany, France, and Italy are at the forefront of innovation in this sector, focusing on producing lightweight and efficient packaging solutions, which are critical in automotive and consumer products. The region is witnessing a shift toward eco-friendly materials driven by consumer preferences and regulatory frameworks aimed at reducing plastic waste. As organizations in Europe increasingly pivot toward sustainability, the demand for advanced blow molded products continues to grow, ensuring the region's relevance in the global market.

Latin America

Latin America's blow molded plastics market is gradually expanding, fueled by emerging economies like Brazil and Mexico, where industrial growth is paving the way for increased demand, particularly in packaging and construction. Although the market is smaller compared to North America and Europe, rising disposable incomes and changing consumer lifestyles are opening new avenues for growth. Challenges such as economic instability and fluctuating raw material prices are present, yet ongoing investments in infrastructure and manufacturing capabilities hold promise for the future of blow molded plastics in this region.

Middle East & Africa

The Middle East & Africa present a niche market for blow molded plastics, primarily driven by the packaging industry, particularly in food and beverage applications. Nations like South Africa and the UAE are leading in terms of production and consumption, with several initiatives aimed at enhancing local manufacturing capabilities. However, the sector faces challenges relating to fluctuating oil prices and political instability in certain regions. Despite these challenges, the region's strategic location for logistics and ongoing investment in infrastructure make it a potential market to watch in the blow molded plastics arena, although it trails behind other regions in overall market size.

Blow Molded Plastics Competitive Landscape:

Major participants in the worldwide blow molded plastics sector are spearheading innovation and product advancements by leveraging cutting-edge manufacturing techniques. They emphasize sustainability and cost-effectiveness to cater to a wide array of consumer preferences. Their strategic alliances and efforts to expand into new markets bolster their competitive edge and foster overall growth within the industry.

Prominent entities within the blow molded plastics industry encompass The Mondi Group, ALPLA Werke Alwin Lehner GmbH & Co KG, Sealed Air Corporation, Inteplast Group, LLC, Graham Packaging Company, Inc., Amcor plc, Berry Global, Inc., Placon Corporation, AOKI Group, and CKS Packaging, Inc. Additionally, significant players include Cepsa, Kautex Maschinenbau GmbH, BERICAP GmbH & Co. KG, RPC Group Plc, and Custom PVC. Furthermore, companies such as Zhangjiagang City Tielong Packaging Machinery Co., Ltd., Fostek Corporation, and Perstorp Group also make noteworthy contributions. These organizations are instrumental in fostering innovation and enhancing competitiveness in the global blow molded plastics market.

Global Blow Molded Plastics COVID-19 Impact and Market Status:

The Covid-19 pandemic profoundly impacted the worldwide market for blow molded plastics, causing a suspension in production and altering consumer preferences, especially within industries such as automotive and packaging.

The COVID-19 outbreak had a profound impact on the blow molded plastics sector, presenting a mix of obstacles and prospects. In the early stages, lockdown measures and interruptions in supply chains led to a decline in production capabilities and delays in the supply of raw materials, which hindered market expansion. Conversely, there was a surge in demand for vital goods, notably in the medical and hygiene sectors, which increased the utilization of blow molded plastics for healthcare packaging and sanitation items. Moreover, the rise in e-commerce and food delivery services during the pandemic further amplified the need for blow molded plastic containers and bottles. As industries work towards recovery in the post-pandemic era, the market is anticipated to bounce back, propelled by advancements in sustainable materials and enhanced recycling initiatives in response to growing environmental awareness. Ultimately, the pandemic served as a significant driver of transformation, encouraging manufacturers to improve their adaptability and responsiveness to evolving market needs.

Latest Trends and Innovation in The Global Blow Molded Plastics Market:

- In September 2023, Graham Partners announced the acquisition of the blow molded plastics manufacturer Sprinter, expanding its portfolio in innovative packaging solutions and strengthening its position in the consumer goods sector.

- In July 2023, Berry Global finalized its acquisition of Clopay Plastic Products Company, aiming to enhance its blow molding capabilities and improve sustainability initiatives through advanced recycling technologies.

- In June 2023, the partnership between A. Schulman and M. Holland Company was announced, focusing on developing new blow molded plastic products with enhanced properties for the automotive and industrial sectors.

- In April 2023, Winpak Ltd. made significant strides in technology innovation by launching a new line of bioplastics for blow molding applications, catering to the growing demand for sustainable packaging solutions.

- In March 2023, Alpla announced the opening of a new manufacturing facility in Slovenia, dedicated to producing high-quality blow-molded plastic products for the European market, thereby increasing its production capacity and geographic reach.

- In February 2023, the collaboration between Perpetual Plastics and Kiefel GmbH focused on integrating advanced automation in blow molding processes, which promised increased efficiency and reduced production costs.

- In January 2023, the investment by Coca-Cola in a new blow molding facility in Mexico aimed to enhance its production of sustainable PET bottles, reflecting its commitment to environmental goals while meeting consumer demands.

Blow Molded Plastics Market Growth Factors:

The growth of the blow molded plastics sector is fueled by rising?? in multiple industries including packaging, automotive, and consumer products, alongside innovations in manufacturing techniques.

The Blow Molded Plastics sector is on the verge of substantial expansion, driven by several pivotal influences. Primarily, there is an escalating requirement for lightweight and resilient packaging solutions across diverse industries such as food and beverages, pharmaceuticals, and personal care. This need is catalyzing the use of blow molded plastics. As businesses strive to optimize costs while enhancing product safety, the adaptability of blow molding technology allows for the efficient creation of intricate shapes with reduced waste.

Moreover, increasing consumer awareness regarding environmental sustainability is urging manufacturers to seek eco-friendly alternatives, including recycled and biodegradable plastics, which can be produced through blow molding processes. Technological advancements in manufacturing, including automation and the implementation of intelligent systems, are further boosting production efficiency and product quality, thus enhancing the competitiveness of blow molded plastics.

The growth of e-commerce and retail also escalates the demand for packaging solutions, which in turn propels market expansion. Additionally, collaborations between manufacturers and end-users aimed at innovating product designs and functionalities are poised to enhance market opportunities. Altogether, these elements are anticipated to uphold the growth trajectory of the Blow Molded Plastics market in the years ahead.

Blow Molded Plastics Market Restaining Factors:

Primary constraints affecting the blow molded plastics industry comprise growing environmental regulations and a notable transition towards eco-friendly materials.

The blow molded plastics sector encounters numerous challenges that could hinder its development. Among these, the instability of raw material costs stands out as a crucial factor, as it deeply influences production expenses and profit margins. Moreover, growing concerns regarding plastic waste, alongside a rise in regulations aimed at limiting plastic consumption, compel manufacturers to explore more sustainable options. Additionally, the competitive landscape is intensified by the emergence of alternative materials, including biodegradable plastics and glass, which threaten traditional blow molded items. The substantial upfront investment needed for cutting-edge blow molding technologies may also act as a barrier for new market entrants. Furthermore, unpredictable demand fluctuations in key industries such as automotive, consumer goods, and packaging can disrupt consistent growth patterns. Nonetheless, as businesses adapt to the increasing focus on environmental sustainability by enhancing recycling processes and creating eco-friendly products, the market may undergo positive transformation. Coupled with ongoing technological innovations and expanding applications across diverse fields, the blow molded plastics market could still experience noteworthy growth opportunities in the years ahead.

Key Segments of the Blow Molded Plastics Market

By Technology

• Extrusion Blow Molding

• Injection Blow Molding

• Stretch Blow Molding

• Compound Blow Molding

By Product

• Polypropylene

• Acrylonitrile Butadiene Styrene

• Polyethylene

• Polystyrene

• Polyvinyl Chloride

• Polyethylene Terephthalate

• Polyamide (Polyamide 6, Polyamide 66)

• Others

By Application

• Packaging

• Consumables & Electronics

• Automotive & Transport

• Building & Construction

• Medical

• Others

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America