Advanced Material Market Analysis and Insights:

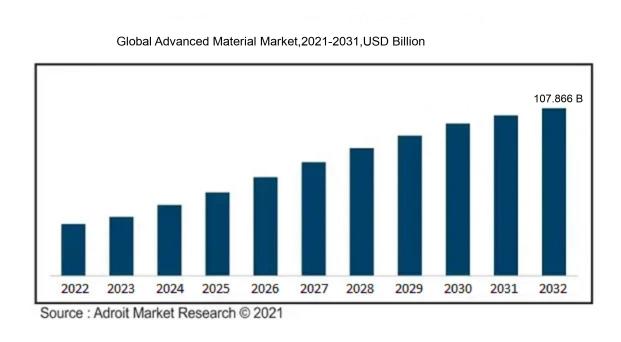

In 2023, the size of the worldwide Advanced Material market was US$ 65.16 billion. Adroit Market Research projects that the market will increase at a compound annual growth rate (CAGR) of 6.49% from 2024 to 2032, reaching US$ 107.866 billion.

The Advanced Materials Market is predominantly propelled by several critical factors, notably the growing necessity for lightweight and high-performance materials in sectors such as aerospace, automotive, and construction. Breakthroughs in nanotechnology and composite materials are accelerating market advancement by improving the capabilities of these materials, enabling the creation of products that are efficient and sustainable. The increasing focus on energy efficiency and environmental responsibility is also driving the uptake of advanced materials, which frequently provide enhanced thermal and mechanical attributes. Furthermore, significant progress in manufacturing techniques, including 3D printing and automation, is streamlining the production of intricate materials and components, thus broadening their applications. In addition, government backing and financial investment in research and development related to advanced materials are nurturing innovation and aiding market growth, as industries strive to boost their competitiveness while adhering to rigorous regulatory requirements.

Advanced Material Market Definition

Cutting-edge materials are meticulously designed substances that demonstrate exceptional characteristics, improving functionality across diverse sectors, including electronics, energy solutions, and biomedical applications. These materials frequently incorporate aspects of nanotechnology, composite structures, and intelligent materials to fulfill the specific requirements of contemporary technological advancements.

Cutting-edge materials play a pivotal role in fostering innovation in multiple sectors, including aerospace, healthcare, and renewable energy. These materials possess superior attributes such as enhanced strength, reduced weight, and better resistance to heat and corrosion, facilitating the creation of more efficient and sustainable products. For example, materials like graphene and carbon nanotubes are transforming the fields of electronics and energy storage, while intelligent materials that respond to environmental changes provide groundbreaking solutions in robotics and self-healing technologies. The advancement of such materials not only stimulates economic development but also tackles pressing global issues like climate change and resource limitations, rendering them vital for future progress.

Advanced Material Market Segmental Analysis:

Insights On Product Type

Polymers

Among the various types, polymers are expected to dominate the Global Advanced Material Market. This is primarily due to their versatility, lightweight nature, and cost-effectiveness. Unique properties such as durability, flexibility, and ease of processing make polymers the preferred choice in several industries like aerospace, automotive, and construction. Furthermore, the increasing demand for sustainable and biodegradable materials is boosting the growth of the polymer. Innovations in polymer technology, such as the development of advanced composites and thermoplastics, are also contributing to their leading position. The widespread application of polymers in high-performance applications further reinforces their dominance in the market.

Metal & Alloys

Metals and alloys are critical players in the advanced materials sector. They are renowned for their strength, durability, and thermal conductivity, making them extensively used in industries such as aerospace, automotive, and electronics. Despite facing competition from alternative materials, advancements in metallurgical engineering and the development of high-performance alloys are enhancing their appeal. Additionally, the need for lightweight yet strong materials has spurred innovations like titanium and aluminum alloys in various applications. Therefore, while metals and alloys remain important, their growth trajectory continues to be challenged by the advancements in polymer technologies.

Glasses

Glasses hold a significant position in the advanced materials market, primarily due to their optical clarity and chemical resistance. They are used in applications ranging from electronics to medical devices and architecture. Innovations in glass manufacturing, such as smart and laminated glass technology, have broadened their applicability. However, the challenges of fragility and weight compared to other materials tend to limit their overall market growth. Nonetheless, the ongoing research in improving glass performance and enhancing functionalities ensures that they continue to maintain a steady presence in specific industries.

Composites

The composites market is growing rapidly, driven by the demand for lightweight and high-strength materials in aerospace, automotive, and construction. Composite materials combine different properties from their constituents, offering enhanced performance compared to traditional materials. Innovations in manufacturing techniques, like additive manufacturing and advanced layering technologies, are also contributing to their increasing use. However, challenges like the relatively high costs of raw materials and processing impact their broader adoption. Despite these barriers, the potential for composites in niche applications continues to foster growth in this.

Ceramics

Ceramics are well-regarded for their high-temperature resistance, hardness, and electrical insulating properties, making them essential in various industrial applications. They play a crucial role in specialty areas like aerospace components, biomedical devices, and electronics. Although the market for ceramics is growing, it faces competition from other materials with enhanced flexibility and weight profiles. Innovations in advanced ceramics, such as bio-ceramics and ceramic matrix composites, are expanding their application scope. However, issues relating to brittleness and processing limitations can hinder their wider acceptance in mainstream applications.

Insights On Application

Automotive

The automotive sector is anticipated to dominate the Global Advanced Material market due to the rapid evolution of lightweight materials aimed at enhancing fuel efficiency and performance in vehicles. With increasing environmental regulations and the push towards electric vehicles, manufacturers are emphasizing the use of advanced materials, such as carbon fiber, composites, and lightweight metals, to meet these challenges. Innovations in materials science are enabling the production of components that provide both strength and reduced weight, which is crucial in improving the overall efficiency of vehicles. The growing trend towards automated and connected vehicles also creates demand for advanced materials in electrical components, ensuring that the automotive category leads the market.

Medical Devices

The medical devices sector demonstrates significant growth due to the rising demand for advanced technologies in healthcare. Innovations in bio-compatible materials are essential for devices like implants, prosthetics, and diagnostic equipment. The emphasis on patient safety and comfort further fuels the need for materials that can lead to improved medical outcomes and reduced infection rates. As healthcare providers invest in state-of-the-art technologies, the integration of advanced materials in medical devices will continue to be a priority, driving demand in this area.

Aerospace

The aerospace industry is characterized by its high performance and safety standards, which drives the demand for advanced materials. Lightweight composites and metals are increasingly being used in aircraft construction to reduce fuel consumption and increase payload capacities. The expansion of commercial aviation and advancements in space exploration significantly contribute to the need for specialized materials that can withstand extreme conditions. Continuous innovations aimed at improving efficiency and safety propel the aerospace sector's demand for advanced materials, highlighting its critical role in the industry.

Electricals & Electronics

The electricals and electronics sector is rapidly evolving with the integration of advanced materials that enhance performance and efficiency. The demand for lightweight, durable components in consumer electronics is rising, driven by trends towards smaller devices with greater functionality. Advanced materials like graphene and conductive polymers are at the forefront of innovations in this area, providing significant improvements in conductivity and energy efficiency. The push for sustainability and energy-saving products reinforces the need for advanced materials, shaping this sector's future growth.

Industrial

The industrial application is increasingly utilizing advanced materials to improve operational efficiencies and reduce costs. High-performance materials are essential for manufacturing processes that require durability and resistance to extreme conditions. Industries such as construction, chemical processing, and manufacturing leverage advanced materials to enhance product performance and reliability. The growing trend towards automation and smart manufacturing further expands the demand for innovative materials that can withstand rigorous industrial applications, making this sector an important contributor to the advanced materials market.

Power

The power sector is experiencing growth fueled by the transition to renewable energy sources, necessitating the use of advanced materials in energy storage and production technologies. High-performance materials are critical in applications such as solar panels, wind energy turbines, and advanced batteries that enhance energy efficiency and output. As the demand for sustainable energy solutions continues to rise, innovations in advanced materials will play a vital role in improving energy systems, thereby promoting substantial growth in this of the market.

Others

The "Others" category includes various additional applications where advanced materials are gaining traction, such as in packaging, consumer goods, and sports equipment. The growth in specialty applications is propelled by innovations that demand enhanced properties such as lightweight, durability, and aesthetic appeal. Advanced materials are influencing product design and functionality across diverse industries, aiding the development of novel solutions that cater to specific consumer needs. While not the leading sector, the diverse applications in the "Others" category contribute meaningfully to the overall growth of the advanced materials market.

Insights On End User

Passenger Cars

Passenger cars are projected to dominate the Global Advanced Material Market due to several factors driving growth in this category. The increased emphasis on lightweight materials to improve fuel efficiency, coupled with the push towards electrification, is leading manufacturers to adopt advanced materials that enhance performance. Innovations such as carbon-fiber composites and high-strength steel not only aid in reducing vehicle weight but also enhance safety and durability. Additionally, the rise of autonomous vehicles generates a demand for advanced materials to support complex functionalities. With a consistent increase in passenger car production and a strong market for electric vehicles, this sector is expected to lead in advanced materials consumption.

Light Commercial Vehicles

Light commercial vehicles are another significant category in the Global Advanced Material Market, though they are positioned behind passenger cars. This benefits from the increasing demand for delivery and logistics services driven by e-commerce growth. As fuel efficiency and payload optimization become crucial, manufacturers are adopting advanced materials such as aluminum and composite materials to enhance vehicle performance. The need for improving operational efficiency in this is prompting further investments in advanced materials, albeit at a slower pace than passenger cars.

Heavy Commercial Vehicles

Heavy commercial vehicles represent a vital part of the Global Advanced Material Market, though they are less dominant compared to passenger cars. The focus in this lies heavily on durability and strength to withstand rigorous use cases in transportation and construction. While there is a slow but steady transition towards lightweight materials for fuel efficiency, the primary materials thus far remain traditional metals. However, increasing regulations and the need for sustainability may drive future demand for advanced materials, but the impact is expected to be gradual. Thus, while important, this is not leading the market.

Insights On Manufacturing Process

3D Printing

3D Printing is anticipated to dominate the Global Advanced Material market due to its innovative approach and capability to produce complex geometries that are often unachievable via traditional manufacturing techniques. The growing demand for customized products across various sectors such as aerospace, automotive, and healthcare is driving the rapid adoption of this technology. Additionally, 3D Printing allows for material efficiency, reduced waste, and rapid prototyping, making it a highly attractive option for manufacturers seeking sustainable practices and cost savings. As industries increasingly pivot toward digital transformation and a circular economy, 3D Printing’s versatility and adaptability position it as a leader in advanced material production.

Injection Molding

Injection Molding remains a strong contender in the advanced materials landscape due to its efficiency in high-volume production. This method is particularly beneficial for creating complex parts with precision and consistency. Moreover, the technology allows for the incorporation of various materials, including polymers and composites, which further enhances its application across industries. The rapid production speed coupled with low per-unit cost makes Injection Molding an attractive option for manufacturers, especially for products that require uniformity and scalability. This method is especially prevalent in consumer goods, automotive components, and electronics, ensuring its continued significance in the market.

Die Casting

Die Casting is favored in the manufacturing of lightweight and durable parts, particularly in the automotive and electronics sectors. This approach utilizes molten metal that is injected into molds, which helps in achieving a high level of detail and finish. The efficiency of Die Casting in terms of both production speed and material usage contributes to its popularity, especially for high-strength components. Furthermore, advancements in alloy materials are enhancing the scope of Die Casting applications, enabling the production of parts that require enhanced thermal and mechanical properties. Its cost-effectiveness in large-scale production makes Die Casting a competitive method in the advanced materials domain.

Machining

Machining plays a critical role in the advanced materials sector, particularly for applications requiring high precision and fine tolerances. This subtractive manufacturing process enables the crafting of intricate and customized components from tough materials, including metals and ceramics. As industries focus on demand for bespoke solutions and quality assurance, Machining offers the flexibility that many manufacturing processes may lack. Additionally, it allows for the easy adjustment of designs and quick turns in production, aligning well with the rapid pace of technological advancement and innovation. However, the comparatively slower production rate can limit its scalability in mass manufacturing scenarios.

Global Advanced Material Market Regional Insights:

Asia Pacific

The Asia Pacific region is expected to dominate the Global Advanced Material market. This can be attributed to the rapid industrialization and increasing demand for advanced materials in countries such as China, India, and Japan. The region is witnessing significant investments in research and development, leading to innovations in materials science, which enhance the manufacturing sectors. Moreover, the growing emphasis on sustainability and eco-friendly products is further driving the demand for advanced materials in applications such as electronics, automotive, and construction. The burgeoning technology landscape and the presence of players in the Asia Pacific region make it a frontrunner in this market.

North America

North America is a player in the Global Advanced Material market, primarily due to its robust technological infrastructure and highly developed manufacturing sector. The region's concentration of leading research institutions and universities fuels innovation, resulting in the development of cutting-edge materials. Moreover, the presence of major companies in aerospace, healthcare, and automotive industries contributes significantly to the demand for advanced materials. Sustainability initiatives and government support for advanced manufacturing are also expected to further boost the market in this region.

Latin America

Latin America shows potential in the Global Advanced Material market, although it currently lags behind other regions. The region is gradually investing in manufacturing and technology, with countries like Brazil and Mexico emerging as players. Increasing urbanization and an expanding middle class are driving demand for advanced materials, particularly in construction and automotive sectors. However, challenges such as economic instability and limited R&D investment hinder faster growth, making it a developing rather than a leading one.

Europe

Europe holds a significant position in the Global Advanced Material market, characterized by stringent regulations and high standards for product quality. The region is known for its innovations in green materials and sustainability-driven technologies. European countries invest heavily in R&D, especially in sectors such as aerospace and electronics, which require high-performance materials. Although challenged by competition from Asia Pacific, Europe is focusing on establishing a circular economy and fostering advancements in smart materials, keeping it competitive in the global landscape.

Middle East & Africa

The Middle East & Africa region is seen as an emerging market in the Global Advanced Material sector. It is increasingly investing in diversifying its economy away from oil dependency, with efforts to develop advanced materials for construction, energy, and technology sectors. While still in the nascent stage compared to other regions, growing investments in infrastructure and smart cities are driving opportunities in advanced materials. However, socio-economic challenges and limited access to advanced manufacturing capabilities present significant barriers to overcoming dominance by other regions.

Advanced Material Market Competitive Landscape:

Leading entities in the global advanced materials sector propel innovation and technological progress through comprehensive research and development initiatives, facilitating the development of superior materials. They cultivate strategic alliances and cooperative efforts to improve product offerings and broaden their market presence.

The Advanced Material Market is prominently shaped by several organizations, including 3M Company, BASF SE, Dow Inc., and DuPont de Nemours, Inc. Other major entities in this sector are Huntsman Corporation, Kuraray Co., Ltd., Mitsubishi Chemical Corporation, Owens Corning, Solvay S.A., Teijin Limited, Covestro AG, Johnson Matthey PLC, and E. I. du Pont de Nemours and Company. Additionally, significant players like AGC Inc., Eastman Chemical Company, SABIC (Saudi Basic Industries Corporation), ArcelorMittal, Nitto Denko Corporation, and Hexcel Corporation are also influential. Furthermore, rising contributors such as Materion Corporation, RTP Company, and Asahi Kasei Corporation are making their mark. Collectively, these companies play a crucial role in the innovation and distribution of advanced materials utilized across a range of industries.

Global Advanced Material Market COVID-19 Impact and Market Status:

The Covid-19 pandemic profoundly impacted the Global Advanced Material market by leading to disruptions in supply chains and altering demand trends in favor of sustainable and innovative materials.

The COVID-19 pandemic profoundly influenced the market for advanced materials, resulting in significant disruptions across multiple industries, including aerospace, automotive, and electronics. At the onset, supply chain issues and production delays led to a decrease in demand for advanced materials, particularly during the periods of lockdown. Nonetheless, as companies adjusted to new safety measures and remote working environments, there was a marked rebound in the demand for lightweight, high-performance materials, notably within the medical and renewable energy sectors. This health crisis catalyzed advancements in materials science, steering research towards the development of sustainable and multifunctional materials that address both health and environmental challenges. Additionally, the increase in investment in infrastructure and technology in the aftermath of the pandemic is anticipated to support a market recovery, thereby improving the long-term growth prospects for advanced materials. In summary, while the pandemic posed immediate challenges, it also spurred innovation and adaptability within the advanced materials industry.

Latest Trends and Innovation in The Global Advanced Material Market:

- In January 2023, 3M announced its acquisition of DuPont's water filtration business for approximately $1.2 billion, enhancing its capabilities in sustainable water solutions and expanding its advanced materials portfolio.

- In March 2023, Henkel acquired the U.S.-based company, AGC Chemicals Americas Inc., a move aimed at strengthening its position in the electronics materials sector and expanding its adhesive technologies.

- In May 2023, BASF and Covestro entered into a strategic partnership to develop innovative materials for electric vehicles, particularly focusing on lightweight solutions that enhance energy efficiency.

- In July 2023, Dow Inc. launched a new line of sustainable silicone-based elastomers aimed at the electric vehicle market, facilitating improved battery performance and safety.

- In September 2023, Solvay announced a partnership with Airbus to develop advanced composite materials for future aerospace applications, showcasing innovations in lightweight and durable materials for aircraft.

- In October 2023, Arkema collaborated with HP to enhance its range of innovative 3D printing materials, aiming to improve the functionality and performance of printed components in various industries.

Advanced Material Market Growth Factors:

The expansion of the Advanced Material Market is propelled by a rising need for superior materials in multiple sectors, innovations in technology, and a ened emphasis on sustainable practices.

The Advanced Materials Market is experiencing notable expansion, influenced by several pivotal elements. Primarily, there is a growing requirement for lightweight and high-performance materials in sectors such as aerospace, automotive, and electronics, as manufacturers aim to enhance fuel efficiency and overall performance. Additionally, the increasing emphasis on sustainability and environmentally friendly alternatives is fostering the innovation of biodegradable and recyclable materials, which aligns with international environmental objectives.

Technological progress, particularly in areas like nanotechnology and 3D printing, is improving material properties and facilitating the creation of cutting-edge products with enhanced attributes. Significant investments in research and development focused on advanced composites and smart materials further support market growth.

The effects of urbanization and infrastructure development in emerging markets are also amplifying the demand for advanced materials within the construction and heavy machinery sectors. Meanwhile, the healthcare industry's ongoing transformation—especially the incorporation of biomaterials in medical devices and implants—highlights the diverse applications and importance of advanced materials.

As industries progressively embrace automation and intelligent technologies, the necessity for advanced materials that satisfy specific technical requirements is poised to sustain the market's upward trajectory. Together, these factors are fostering a promising outlook for the Advanced Materials Market in the foreseeable future.

Advanced Material Market Restaining Factors:

The market for advanced materials encounters difficulties including elevated production expenses, rigorous regulatory standards, and a sluggish embrace of innovations in conventional sectors.

The advanced materials sector encounters numerous obstacles that could hinder its growth potential. Elevated production costs tied to innovative materials, including nanomaterials and composites, pose a significant challenge, often restricting their acceptance in the market, particularly among small and medium enterprises. Furthermore, the intricate nature of the manufacturing processes demands considerable investment in research and development, potentially discouraging new market entrants. Regulatory challenges are also influential, as adhering to environmental and safety regulations can result in delays and ened operational costs. The absence of a well-developed supply chain for specialized materials further diminishes scalability and accessibility, complicating procurement for producers. Additionally, the swift evolution of technology may render some materials outdated, injecting uncertainty into investment choices. Nonetheless, in spite of these hurdles, continuous innovations and a growing need for lightweight, durable, and sustainable materials across various sectors, including aerospace, automotive, and electronics, are creating new avenues for growth. The sector's resilience and capacity for adaptation suggest a favorable future as it shifts to meet the evolving requirements of consumers and industries, fostering advancement in the applications of advanced materials.

Segments of the Advanced Material Market

By Product Type

• Polymers

• Metal & Alloys

• Glasses

• Composites

• Ceramics

By Application

• Medical Devices

• Automotive

• Aerospace

• Electricals & Electronics

• Industrial

• Power

• Others

By End User

• Passenger Cars

• Light Commercial Vehicles

• Heavy Commercial Vehicles

By Manufacturing Process

• Injection Molding

• Die Casting

• 3D Printing

• Machining

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America