3D Printing Construction Market Analysis and Insights:

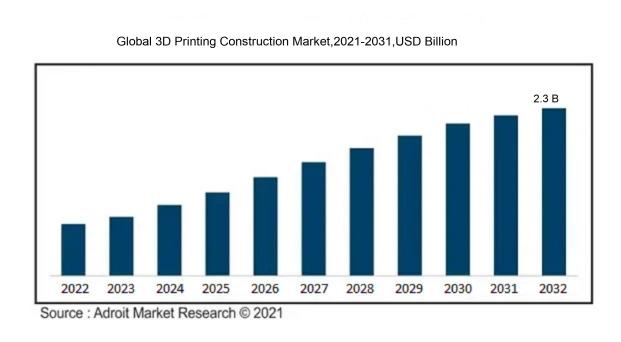

In 2023, the size of the worldwide Global 3D Printing Construction market was US$ 0.33 billion. Adroit Market Research projects that the market will increase at a compound annual growth rate (CAGR) of 166.5% from 2024 to 2032, reaching US$ 2.3 billion.

The 3D Printing Construction Market is largely influenced by the pursuit of cost savings, environmental sustainability, and the increasing necessity for quick construction techniques. Technological innovations have paved the way for advanced printing materials that not only improve structural strength but also minimize waste, attracting environmentally conscious builders and developers. Moreover, the ongoing labor shortages in the construction sector have accelerated the shift towards automated methods, with 3D printing reducing the dependency on human labor. This technology's flexibility enables the creation of unique architectural forms that can be realized with greater ease and shorter timelines. Government initiatives aimed at fostering sustainable construction practices, alongside investments in infrastructure, further boost the market's advancement. Additionally, the growing interconnectedness of the construction industry worldwide is promoting the adoption of technologies that can be customized for diverse project scales and contexts. Collectively, these elements create a conducive landscape for the proliferation of 3D printing in the construction domain.

3D Printing Construction Market Definition

3D printing in construction involves employing additive manufacturing techniques to fabricate structures incrementally from digital blueprints. This progressive method enhances efficiency, minimizes material waste, and opens up possibilities for tailored architectural designs.

The advent of 3D printing in construction is transformative, significantly altering conventional building methodologies by improving operational efficiency, minimizing waste, and decreasing expenses. This cutting-edge technology accelerates the construction process and enables the creation of intricate designs that traditional techniques often struggle to achieve. Moreover, it promotes sustainability through the use of eco-friendly materials and reduces the environmental impact linked to construction activities. Additionally, 3D printing offers rapid solutions for affordable housing, effectively addressing the global shortage of housing and contributing to initiatives aimed at resolving urbanization issues and enhancing living standards worldwide. In essence, it signals a revolutionary advancement towards more intelligent and environmentally sound construction practices.

3D Printing Construction Market Segmental Analysis:

Insights On Material

Concrete

Concrete is expected to dominate the Global 3D Printing Construction Market due to its unique advantages that align with the demands of modern construction. It is not only widely available and cost-effective, but also proves to be highly versatile for a variety of applications, including residential, commercial, and infrastructure projects. The technology surrounding concrete 3D printing has advanced significantly, enabling the efficient construction of complex geometries while reducing material waste and labor costs. Furthermore, concrete's durability and long lifespan make it an optimal choice in construction, allowing for sustainable building solutions that cater to today's ecological concerns. This combination of factors positions concrete as the leading choice in the evolving landscape of 3D-printed constructions.

Metal

Metal has emerged as a prominent choice in 3D printing construction due to its structural strength and aesthetic appeal. Applications of metal in construction, such as steel and aluminum, facilitate the creation of robust frameworks and intricate components that are both lightweight and resilient. Additionally, the advent of advanced metal alloy formulations and additive manufacturing technologies allows for increased design freedom, making it possible to produce custom architectural pieces efficiently. However, the high material costs and complicated post-processing requirements can limit its widespread adoption in comparison to more cost-effective alternatives like concrete.

Composite

Composite materials are gaining traction within the 3D printing construction sector for their ability to combine the properties of different materials, resulting in lightweight yet high-strength structures. Composites can offer enhancements in thermal and electrical insulation, which further expands their applicability in specialized construction scenarios. While still emerging, their potential for innovative designs and customization makes composites an attractive option for architects and engineers. However, issues regarding the long-term durability and recyclability of these materials pose challenges for their broader implementation in the construction industry.

Others

The "Others" category in the 3D printing construction market encompasses a range of alternative materials including ceramics, plastics, and bio-based substances. While these materials may offer unique benefits, such as sustainability or specific application advantages, they currently represent a smaller share of the market compared to traditional options like concrete and metal. Their adoption is often limited to niche applications, where specialized properties are required, such as in art installations or environmentally-friendly structures. As innovations develop further in these material types, they may become more significant contributors to the construction landscape in the future.

Insights On Construction Method

Extrusion

Extrusion is expected to dominate the Global 3D Printing Construction Market due to its versatility and efficiency in producing large structures at a reduced cost. This method allows for continuous production, making it ideal for creating massive components like walls and structures with considerable size and complexity. Additionally, the use of concrete materials in extrusion techniques has gained significant traction, as it aligns well with the construction industry's sustainability goals. Its ability to utilize a range of materials and easily integrate with automated processes supports scalability and reduces labor costs. Extrusion's growing acceptance in the industry and ongoing advancements in material technologies position it as the frontrunner in the market.

Powder Bonding

Powder bonding, while important, is not expected to lead in the 3D Printing Construction Market. This technique, commonly used in metal applications, faces limitations in large-scale construction due to slower build rates and complex material handling requirements. The high precision provided by powder bonding comes at the cost of speed, which is a critical factor in the construction sector. Moreover, this method often necessitates post-processing, increasing time and expenses when compared to extrusion. As a result, while it may find applications in niche projects, it lacks the broad applicability needed to lead the market.

Others

The "Others" category, encompassing various unconventional printing methods, has potential in specialized applications but lacks a significant market share in mainstream construction. Techniques such as binder jetting or directed energy deposition are used occasionally for unique architectural designs or installations but do not yet demonstrate the scalability or speed required for widespread adoption in construction. Market demand is leaning towards cost-effective and time-efficient methods, which limits the growth of this. Furthermore, with ongoing advancements in established processes like extrusion, alternative methods are likely to remain secondary to the more efficient options available.

Insights On End User

Building

The building sector is poised to dominate the Global 3D Printing Construction Market, driven primarily by the growing demand for rapid and cost-effective construction solutions. The need for sustainable building practices and architectural innovation is on the rise, further propelling the adoption of 3D printing technologies in this arena. With urbanization increasing globally, the ability to construct complex structures in shorter timescales appeals to contractors and developers. Additionally, advancements in materials technology are enhancing the structural integrity and aesthetic possibilities of 3D printed buildings, making it an attractive option for residential and commercial construction projects.

Infrastructure

While infrastructure is significant, it takes a secondary role in the Global 3D Printing Construction Market. This sector encompasses large scale projects such as bridges, roads, and utilities, which have traditionally relied on more conventional construction methods. Although there is a shift towards incorporating innovative techniques for creating infrastructure components rapidly and efficiently, challenges such as regulatory approvals and the scale of investment required in infrastructure projects temper the rapid adoption of 3D printing. Nevertheless, advancements in large-scale printing technologies and the increasing focus on sustainable infrastructure may lead to a gradual rise in this area.

Global 3D Printing Construction Market Regional Insights:

Asia Pacific

The Asia Pacific region is poised to dominate the Global 3D Printing Construction market due to several compelling factors. Rapid urbanization, especially in countries like China and India, is driving a need for innovative construction solutions to meet the demands of growing populations. The region's increased focus on sustainability and eco-friendly building practices is further propelling the adoption of 3D printing technologies. Additionally, significant investments in infrastructure development and advancements in materials science are enhancing the capabilities and affordability of 3D printing in construction. With a strong presence of players and research institutions dedicated to this technology, Asia Pacific is set to lead the market over the coming years.

North America

North America stands as a significant player in the Global 3D Printing Construction market, driven primarily by technological advancements and robust investment in R&D. The United States, specifically, has seen substantial growth in the adoption of 3D printing technologies due to an increasing number of startups and construction firms integrating these solutions into their operations. Furthermore, government initiatives aimed at promoting innovation in construction practices bolster growth. However, while the North American market is doing well, it is currently not as expansive as the opportunities presented in the Asia Pacific region.

Europe

Europe has shown promising potential in the Global 3D Printing Construction market, backed by strong regulatory frameworks focusing on sustainability and innovation. Countries such as Germany, France, and the Netherlands have pioneered initiatives that emphasize eco-friendly construction methods, promoting the adoption of 3D printing technologies. Collaborative efforts between academia and industry in Europe enhance research capabilities, leading to innovative applications in construction. While Europe continues to grow in this sector, it faces strong competition from the more rapidly advancing markets in Asia Pacific.

Latin America

Latin America is a developing market in the realm of 3D Printing Construction, with a gradual adoption of this technology primarily driven by rising construction costs and the need for affordable housing solutions. Countries like Brazil and Mexico are beginning to explore 3D printing as a means to streamline construction processes and reduce waste. However, the market is still in its infancy as infrastructure and investment in technology lag behind more developed regions. With time, growth may be seen as more construction firms explore novel solutions, yet challenges persist.

Middle East & Africa

The Middle East and Africa region presents unique challenges and opportunities within the Global 3D Printing Construction market. The emphasis on smart cities and modern infrastructure within the Gulf States is fostering some interest in 3D printing technology among local construction firms. However, a lack of widespread infrastructure, research, and investment poses significant hurdles. Countries like South Africa and the UAE are showing potential for growth, but the region overall needs more substantial backing in both funding and technology transfer to fully develop its market potential.

3D Printing Construction Market Competitive Landscape:

Leading figures in the global 3D printing construction industry are at the forefront of innovation and technological progress, prioritizing both cost-effectiveness and the acceleration of construction processes. These stakeholders work in partnership with architects, engineers, and governmental bodies to promote sustainable building methods and increase the widespread acceptance of this technology.

Prominent entities within the 3D printing construction industry comprise ICON, Apis Cor, SIKA, Contour Crafting, Velov Engineering, 3D Construction Printing, CERAMA, StrucSoft Solutions, XtreeE, WASP, Cazza Construction, SEArch+, and CyBe Construction.

Global 3D Printing Construction Market COVID-19 Impact and Market Status:

The Covid-19 pandemic acted as a catalyst for innovation and faster implementation within the global 3D printing construction sector. In response to challenges such as supply chain breakdowns and workforce shortages, the industry turned to automated and efficient building methods.

The COVID-19 pandemic had a profound impact on the 3D printing construction sector, initially causing delays in projects and disrupting supply chains due to imposed restrictions and a shortage of labor. With a slowdown in construction activities, numerous companies reassessed their operational strategies, discovering the advantages of 3D printing for mitigating issues like high labor expenses and extended project durations. The crisis spurred a ened interest in automation and novel construction techniques aimed at improving efficiency and safety, leading to increased investments in 3D printing technologies. Furthermore, the urgent need for cost-effective and rapid housing solutions during the pandemic intensified the demand for 3D printed buildings, especially in areas grappling with shortages in housing. As the industry begins to stabilize, the uptake of these technologies is projected to rise, driven by growing concerns regarding sustainability and advancements in materials and methods. In summary, although the pandemic posed significant challenges, it also acted as a catalyst for a shift towards innovative construction practices that may transform the industry in the future.

Latest Trends and Innovation in The Global 3D Printing Construction Market:

- In October 2023, ICON unveiled its partnership with BIG (Bjarke Ingels Group) to develop a new line of 3D-printed homes designed for affordability and sustainability, addressing the growing demand for housing solutions.

- In August 2023, SE3D announced the successful completion of a multi-million dollar merger with Apis Cor, combining their resources and technologies to enhance the capabilities and market reach of large-scale 3D construction printing.

- In June 2023, WASP (World’s Advanced Saving Project) revealed its new "Delta WASP 3D" printer, capable of using local, sustainable materials like mud and clay. This innovation aims to revolutionize eco-friendly construction practices.

- In March 2023, CoBlox was awarded a $10 million contract to print homes in a disaster-stricken area in Tur, showcasing the effectiveness of 3D printing in rapid response and reconstruction efforts.

- In February 2023, Vertico completed the construction of the world's first fully 3D-printed building in the Netherlands, marking a significant milestone in architectural and construction practices.

- In January 2023, SQ4D announced the sale of the first 3D-printed home in the United States, which was sold for $300,000, highlighting the commercial viability of 3D-printed residential properties.

- In November 2022, Contour Crafting revealed advancements in its robotic 3D printing systems that allow for faster construction rates and larger-scale projects, potentially transforming urban development.

- In July 2022, Habitat for Humanity collaborated with ICON to create affordable housing in Austin, Texas, utilizing 3D printing technology to reduce construction time and costs.

3D Printing Construction Market Growth Factors:

The primary drivers of expansion in the 3D printing construction sector encompass innovations in material technologies, a growing need for economical housing solutions, and ened governmental backing for eco-friendly construction methodologies.

The market for 3D printing in construction is witnessing robust expansion, fueled by several crucial elements. Primarily, the escalating need for affordable housing solutions due to urbanization and increasing population density is driving the uptake of 3D printing technology, which stands to significantly cut both construction costs and timelines. Furthermore, innovations in materials like advanced concrete blends and thermoplastics have improved the resilience and sustainability of 3D-printed buildings. In addition, ened environmental awareness is nudging the sector towards greener practices; 3D printing holds the promise of waste reduction and efficient use of recycled materials. Government support and funding aimed at fostering novel construction techniques are also playing a vital role in the growth of this market. The incorporation of automation and robotics into 3D printing processes boosts efficiency and accuracy, making the approach appealing to contractors and builders alike. Additionally, the proliferation of digital fabrication methods and the rise in collaborative efforts within the industry are driving innovation and further propelling market advancement. Lastly, a growing consumer inclination towards tailored and distinctive architectural designs enabled by 3D printing technology is contributing to the swift evolution of the market. Collectively, these factors underscore the transformative impact of 3D printing on the construction industry.

3D Printing Construction Market Restaining Factors:

The growth of the 3D printing construction sector is significantly impeded by several obstacles, such as elevated material expenses, regulatory challenges, and a lack of awareness among prospective users.

The market for construction through 3D printing encounters a variety of challenges that could hinder its expansion. One of the primary obstacles is the substantial upfront investment required for cutting-edge machinery and technology, which can inhibit participation from small and medium-sized enterprises. Furthermore, the absence of standardized regulations and building codes tailored to 3D-printed constructions can lead to ambiguity for stakeholders, ultimately discouraging both investment and widespread adoption.

The shortage of skilled labor adept in 3D printing methods compounds these issues, as many traditional construction workers may find it difficult to adapt to the nuances of advanced printing equipment. Additionally, doubts regarding the durability and long-term reliability of structures produced using 3D technology may undermine client trust. Fluctuations in the prices of raw materials also introduce financial uncertainties, challenging companies' efforts to remain cost-effective. Finally, the integration of 3D printing technology with existing construction processes presents another hurdle, necessitating adjustments to traditional workflows.

Despite these impediments, the future of the 3D printing construction market appears optimistic, fueled by continuous research and development, advances in technology, and a growing focus on sustainable building practices, all pointing towards enhanced innovation and efficiency in the industry.

Segments of the 3D Printing Construction Market

By Material

• Metal

• Composite

• Concrete

• Others

By Construction Method

• Powder Bonding

• Extrusion

• Others

By End User

• Infrastructure

• Building

Regional Overview

North America

• US

• Canada

• Mexico

Europe

• Germany

• France

• U.K

• Rest of Europe

Asia Pacific

• China

• Japan

• India

• Rest of Asia Pacific

Middle East and Africa

• Saudi Arabia

• UAE

• Rest of Middle East and Africa

Latin America

• Brazil

• Argentina

• Rest of Latin America