3D Printed Wearable Market Analysis and Insights:

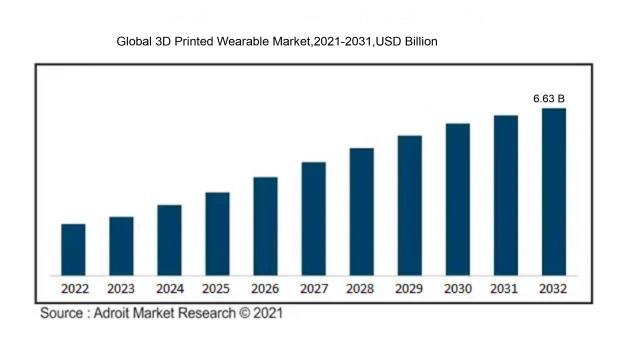

In 2023, the size of the worldwide Global 3D Printed Wearable market was US$ 0.97 billion. Adroit Market Research projects that the market will increase at a compound annual growth rate (CAGR) of 23.66% from 2024 to 2032, reaching US$ 6.63 billion.

The expansion of the market for 3D printed wearables is influenced by several pivotal factors. Innovations in 3D printing techniques and materials have facilitated the production of highly tailored products that align with the specific preferences of users. Concurrently, the rising popularity of personalized wearable technologies across industries such as healthcare, fashion, and fitness highlights a consumer demand for distinctive solutions that improve both comfort and utility. Furthermore, the growing integration of smart wearable devices, paired with an increased emphasis on health and wellness, has driven advancements in both design and functionality. Environmental sustainability also plays a vital role, with manufacturers capitalizing on 3D printing to reduce waste and incorporate sustainable materials. Lastly, partnerships between technology firms and fashion designers are enhancing creative possibilities and broadening the range of available products, thus making 3D printed wearables more enticing to a wider demographic.

3D Printed Wearable Market Definition

A wearable device manufactured through 3D printing is an item of apparel or accessory produced via additive fabrication methods, facilitating complex designs and tailored options. These innovative items merge technological advancements with fashion, offering individualized fitting and features.

Wearable technology achieved through 3D printing marks a notable step forward in the realm of personalized devices, providing solutions that improve comfort, utility, and aesthetics. This cutting-edge approach streamlines the prototyping process, enabling designers to produce bespoke items with greater efficiency and lower costs. The incorporation of diverse materials and functionalities allows these wearables to track health indicators, aid in rehabilitation, and enhance everyday experiences, thus contributing to an improved quality of life. Furthermore, 3D printing minimizes material waste and fosters sustainable practices within manufacturing. With the rising demand for custom-fit alternatives, 3D printed wearables are poised to bridge the divide between technological innovation and personal identity, transforming various sectors in the process.

3D Printed Wearable Market Segmental Analysis:

Insights On Type

Clothing

Clothing is poised to dominate the Global 3D Printed Wearable Market due to the increasing demand for personalized and customizable fashion. As consumers seek unique styles that reflect their individuality, brands leveraging 3D printing technology have surged ahead by offering bespoke clothing solutions that cater to specific tastes. The market is further fueled by advancements in fabric technology that enhance comfort and functionality, making 3D printed apparel not just an aesthetic choice but also a pragmatic one. Additionally, the sustainable aspects of 3D printing, such as waste reduction and the ability to recycle materials, resonate with environmentally-conscious consumers, further solidifying clothing's leading position in this rapidly evolving market.

Footwear

Footwear stands as a crucial player in the Global 3D Printed Wearable Market, driven by innovations in comfort and performance. The ability to create tailored insoles and athletic shoes perfectly fitted to individual foot shapes is highly appealing to both sports enthusiasts and everyday consumers. Brands are increasingly utilizing 3D printing to enhance design capabilities and reduce production times, leading to more agile responses to market trends. Moreover, the intersection of fashion and functionality in 3D-printed footwear offers countless opportunities for brands to differentiate themselves in a competitive landscape, making this category significant, although slightly behind clothing in terms of market dominance.

Accessories

Accessories represent a growing niche in the Global 3D Printed Wearable Market, as they allow consumers to express individuality without the commitment of a full outfit. As wearable technology gains traction, the integration of 3D printing into items like custom jewelry, eyewear, and wearable tech introduces a unique blend of fashion and functionality. The lightweight nature of 3D printed materials makes accessories not only stylish but also comfortable for prolonged use. Furthermore, trends in tech-driven personalization, such as customizable smartwatch bands and phone cases, are positively impacting the accessory, albeit it remains smaller compared to clothing and footwear in terms of overall market dominance.

Insights On Material Type

Thermoplastics

Thermoplastics are expected to dominate the Global 3D Printed Wearable Market due to their versatility, strength, and durability. As consumer demand for personalized and functional wearable products rises, thermoplastics offer a range of options that can be easily molded into various shapes and sizes without compromising performance. This material type is favorable for applications requiring flexibility, such as fitness trackers and smart apparel, where comfort and wearability are crucial. Additionally, the ease of processing and the ability to recycle thermoplastics make them an attractive choice for manufacturers aiming for sustainability while meeting the growing market needs. The innovative potential within this category leads to its anticipated dominance.

Bio-based Materials

Bio-based materials are gaining traction in the 3D printed wearable market as consumers become increasingly eco-conscious. These materials are derived from renewable sources and offer a more sustainable alternative to petroleum-based options. With advances in technology, the performance of bio-based materials has improved, allowing for better durability and functionality. Additionally, their biodegradability resonates with the growing demand for environmentally friendly products. However, they still face challenges concerning cost and material properties that may limit their widespread adoption in high-performance applications.

Metals

Metals are significant players in the 3D printed wearable market, primarily due to their strength and durability. However, their use is often confined to specialized applications, such as prosthetics and high-end wearable devices where performance requirements are stringent. The high cost of metal 3D printing and the complexities involved in processing metal materials may restrict their broader uptake compared to more versatile options like thermoplastics. Despite these challenges, the unique qualities of metals—like structural integrity and aesthetic appeal—keep them in the market, especially where robustness is prioritized.

Insights On Printing Technology

Fused Deposition Modeling

Fused Deposition Modeling (FDM) is set to dominate the Global 3D Printed Wearable Market. It is widely recognized for its ease of use and cost-effectiveness, making it a popular choice among small-scale manufacturers and DIY enthusiasts in the 3D printed wearable sector. This technique utilizes thermoplastic materials that can be easily sourced and are relatively inexpensive, thus promoting rapid prototyping and development. FDM excels in producing prototypes and functional models quickly, allowing designers to iterate on wearable technology designs efficiently. While not as advanced as SLS in terms of material properties, FDM is still significant in developing entry-level wearable devices and proofs-of-concept, giving designers a way to explore innovative forms before considering more sophisticated methods.

Selective Laser Sintering

Selective Laser Sintering (SLS) is growing due to its superior capabilities in producing complex geometries and high-strength materials that are essential for wearable technology. SLS allows for the creation of lightweight, durable components that can seamlessly integrate into devices such as fitness trackers, health monitors, and smart clothing. With the increasing demand for tailored and ergonomic products that cater to individual users, SLS offers unmatched customization potential. The technology's ability to work with a wide range of materials, including thermoplastics and metals, further enhances its appeal in the wearable market. As manufacturers focus on innovation and improving functionality, SLS is positioned as the frontrunner.

Multi-jet Modeling

Multi-jet Modeling (MJM) is a promising method of 3D printing that delivers high-resolution parts with excellent surface finish. The technology involves depositing materials layer by layer using print heads, allowing for intricate detail and fine features in wearable devices. While MJM offers precision, its slower production speed and higher costs compared to SLS and FDM may hinder widespread adoption in high-volume applications. MJM is particularly suitable for creating complex prototypes and low-volume production runs where aesthetics and detail are critical, making it relevant for specialized markets within the wearable sector. As demand for customizable and visually striking wearables increases, MJM's precision-oriented approach can cater to niche s effectively.

Insights On Application

Healthcare

The healthcare sector is expected to dominate the Global 3D Printed Wearable Market due to its increasing demand for personalized medical solutions and monitoring devices. Innovations in 3D printing technology have made it possible to create wearable devices tailored to individual patient needs, such as prosthetics, implants, and biocompatible materials used in medical devices. This market is driven by the advancements in healthcare technologies, rising patient awareness, and the growing prevalence of chronic diseases that require continuous monitoring. Furthermore, partnerships between tech companies and healthcare organizations to develop tailored solutions indicate a strong trend towards investing in this area. The focus on personalized medicine enhances the potential for significant growth and expansion within this field.

Fashion

Fashion, while a player in the 3D Printed Wearable Market, is not expected to lead in growth rates compared to healthcare. However, the integration of 3D printing into apparel and accessory design allows for superior customization and rapid prototyping, enabling designers to bring innovative concepts to life efficiently. Collaborative projects between fashion brands and technology companies have highlighted the merging of art and technology, resulting in unique wearable pieces that also appeal to sustainability trends. As more consumers demand unique styles, 3D printing can address these needs, though the health sector's greater necessity for advancements holds the potential for a larger market share.

Sports and Recreation

The sports and recreation is gaining traction in the 3D Printed Wearable Market by focusing on enhancing performance and user experience. Wearable tech in this area includes custom-fitted equipment designed to improve athletes' performance, such as sportswear and accessories that provide real-time feedback. The increasing trend of wearables that track performance metrics further contributes to its growth, as athletes and fitness enthusiasts seek advanced solutions to gain a competitive edge. However, despite its potential for innovation, sports and recreation applications currently cater to a niche market compared to the broader healthcare requirements, which places them at a lower growth trajectory overall.

Insights On Sales Channel

Online Marketplaces

Online marketplaces are expected to dominate the Global 3D Printed Wearable market due to their expansive reach and ease of access for consumers. Companies like Amazon, Etsy, and other dedicated platforms significantly enhance distribution capabilities, allowing consumers worldwide to explore and purchase innovative wearable products. Additionally, the growing trend of e-commerce coupled with increased internet penetration ensures that consumers prefer online channels for convenience and variety. The ability for customers to read reviews, view detailed product descriptions, and often engage directly with sellers further boosts their confidence in buying innovative wearable technology, solidifying the dominance of online marketplaces in this sector.

Retail Stores

Retail stores play an essential role in the Global 3D Printed Wearable market, providing customers with a tactile experience that online platforms cannot offer. Consumers often prefer visiting physical stores to try on wearables, ensuring fit and comfort before making a purchase. Retail locations can enhance brand visibility and allow for direct engagement with customers, creating a personal shopping experience. However, the traditional retail landscape faces challenges in adapting to rapid technological advancements, which makes them less dominant compared to online options. Nevertheless, established brands may still maintain a competitive edge via flagship stores and partnerships with other retail giants.

Direct-to-Consumer

The direct-to-consumer sales channel has gained traction, especially among companies looking to establish a close relationship with their customers. By eliminating intermediaries, brands can maintain better control over pricing and customer experience while offering unique products that appeal to niche markets. This approach often leads to higher customer loyalty as brands can engage directly through marketing strategies tailored to their audience's preferences. However, while valuable, this channel currently does not reach the broader audience available through online marketplaces, limiting its overall market dominance in the expanding 3D Printed Wearable industry.

Global 3D Printed Wearable Market Regional Insights:

Asia Pacific

The Asia Pacific region is expected to dominate the Global 3D Printed Wearable market due to its rapidly advancing technology, increasing investment in research and development, and the concentration of manufacturers. Countries like China, Japan, and South Korea are at the forefront of adopting 3D printing technology, particularly in health and fitness wearables, which has seen a surge in demand. Moreover, a growing young population eager for innovative technology and personalized products supports market growth. Additionally, supportive government initiatives aimed at promoting advanced manufacturing technologies further enhances the region's competitive edge in the wearable market.

North America

North America is a critical player in the Global 3D Printed Wearable market, primarily driven by technological advancements and a well-established healthcare framework. The U.S. leads the charge with significant investments in 3D printing technologies for healthcare and apparel, catering to consumer demand for customized and innovative wearable solutions. Furthermore, a mature retail landscape supports the growth of 3D printed wearables, making the region a focal point for product launches and consumer engagement. Despite being a strong contender, North America may take a more secondary position compared to the fast-growing Asia Pacific market.

Europe

In Europe, the 3D Printed Wearable market is characterized by a strong focus on sustainability and innovation. European manufacturers prioritize eco-friendly materials and ethical production processes, appealing to increasingly environmentally conscious consumers. Countries like Germany and the UK are investing significantly in R&D related to 3D printing capabilities, especially in the fashion and healthcare sectors. While growth is robust, Europe's regulatory complexities and varying consumer preferences across nations can temper market expansion, thus positioning it behind Asia Pacific and North America but still offering unique opportunities.

Latin America

Latin America is experiencing gradual growth in the 3D Printed Wearable market, driven by an emerging technology landscape and increasing awareness of the benefits of 3D printing. The region is beginning to see applications in sports and fitness wearables, tailoring products to local needs and preferences. However, the market is challenged by economic instability and a lack of robust infrastructure for advanced manufacturing technologies. While there is potential for growth, Latin America currently lags behind more developed markets, necessitating further investment and development to compete effectively on a global scale.

Middle East & Africa

The Middle East & Africa region is at the nascent stage of adopting 3D Printed Wearable technology. While there is burgeoning interest in innovation and a youthful population keen on technology, the market faces hurdles such as limited investment and infrastructure challenges. Countries like South Africa and the UAE are showing promise through initiatives to foster technology-driven sectors, yet the pace of adoption remains slow compared to other regions. The market's potential is significant, but overcoming economic challenges and building technology ecosystems will be crucial for future growth in this area.

3D Printed Wearable Market Competitive Landscape:

Leading figures in the worldwide market for 3D printed wearables are at the forefront of innovation by pioneering sophisticated printing techniques and tailored designs, thereby elevating user experience and enhancing product functionality. Additionally, they are pivotal in partnering with diverse sectors to broaden the scope of applications and facilitate the seamless incorporation of wearable technology into daily routines.

Prominent entities in the 3D printed wearable sector encompass Fitbit, Nike, Adidas, Under Armour, RHEON Labs, Stratasys, Materialise, 3D Systems, Carbon, Shapeways, Continuum Applied Technology, EnvisionTEC, HP, Ripe Robotics, and Organoid Technologies. Furthermore, other significant contributors to this field include Ecole Polytechnique Fédérale de Lausanne (EPFL), University of Illinois at Urbana-Champaign, Revivo Medical, Axial3D, and Tactotek. The wider realm of 3D printed wearable technologies also comprises companies such as NanoDimension, Create O, IPI & Co., and Creaform.

Global 3D Printed Wearable Market COVID-19 Impact and Market Status:

The Covid-19 pandemic significantly propelled the advancement and use of 3D printed wearable technology, driven by an increased need for tailored personal protective gear and health monitoring tools.

The COVID-19 pandemic had a profound impact on the market for 3D printed wearables, driving both innovation and demand, especially in personal protective equipment (PPE) and health monitoring technologies. With healthcare systems being heavily tested, the rapid prototyping capabilities inherent in 3D printing enabled the swift manufacturing of essential items such as face shields, masks, and ventilator parts, critical for curbing the virus's spread. Furthermore, the crisis sparked increased consumer interest in health and fitness, leading to a surge in the development of wearables designed to monitor important health metrics and support overall well-being. This period saw companies actively pursuing tailored solutions, enhancing the personalization features of their wearables, which appealed to consumers seeking insights into their individual health statuses. The shift towards digital health solutions and remote patient monitoring allowed 3D printing to firmly establish its role in developing customized, innovative devices. This indicates a sustained potential for market expansion beyond the pandemic, as the emphasis on health and safety remains a priority.

Latest Trends and Innovation in The Global 3D Printed Wearable Market:

- In September 2022, Adidas collaborated with Carbon to innovate in 3D printed footwear, launching the 4D performance running shoe line, which utilizes cutting-edge Digital Light Synthesis technology to create precise lattice structures for improved comfort and performance.

- In March 2023, Fit3D announced its acquisition of 3DLOOK, enhancing its portfolio and capabilities in body scanning and 3D printing technology, aimed at revolutionizing the customized apparel market.

- In June 2023, Nike unveiled the "Nike ISPA (Improvise, Scavenge, Preserve, Adapt)" collection which integrates 3D printing techniques in creating sustainable footwear designs that emphasize circular economy practices.

- In April 2023, Stratasys and 3D Systems announced a partnership focusing on advancements in 3D printing technologies specifically designed for wearable tech, aiming to facilitate the production of personalized and adaptive wearables.

- In January 2022, Under Armour introduced its first 3D printed shoe, the UA Flow Velociti, which features a unique 3D printed midsole created to improve athlete performance and reduce environmental impact by minimizing materials used in shoe production.

- In February 2023, ECCO partnered with the AM (Additive Manufacturing) company HP Inc. to develop a 3D printed cap-toe sneaker to reduce waste and increase customization options for consumers, showcasing an innovative approach to sustainable fashion.

- In August 2023, New Balance debuted their first 3D printed footwear model using advanced additive manufacturing processes, focusing on personalized cushioning tailored to individual user needs, showcasing a significant step in the personalized wearables market.

- In November 2022, the fashion brand PUMA announced a collaboration with Zellerfeld, a 3D printing company, to launch a fully 3D printed sneaker line designed to enhance fit and comfort while promoting sustainability through localized production.

- In December 2022, L’Oréal initiated a joint venture with 3D printing specialist, AdiFab, to create customizable skincare wearables that capture data on skin health, emphasizing the intersection of beauty and innovative technology.

- In October 2023, the Swedish company Paptic announced its new 3D printed wearable packaging, focusing on sustainability and replacing traditional plastic with bio-based materials in the fashion industry.

3D Printed Wearable Market Growth Factors:

The expansion of the market for 3D-printed wearables is fueled by innovations in customization technologies, a growing desire for individualized health solutions, and the increasing prevalence of smart wearable technology.

The market for 3D printed wearables is witnessing remarkable growth, influenced by several crucial elements. First and foremost, improvements in 3D printing technology have significantly increased production efficiency, allowing for the development of personalized wearable devices that are specifically designed to meet individual needs, thus enhancing comfort and functionality. Additionally, the rising interest in tailored fitness and health monitoring solutions has stimulated innovation within the industry, as consumers are actively looking for devices that align with their unique lifestyles. The escalating incidence of chronic illnesses also emphasizes the necessity for ongoing health monitoring, which in turn boosts the demand for advanced wearable technology.

The incorporation of smart technologies—like the Internet of Things (IoT) and artificial intelligence—plays a vital role in expanding the market by enabling real-time data gathering and analysis, which enhances user engagement. Furthermore, the increasing recognition of the advantages of 3D printing, particularly in minimizing material waste and reducing production expenses, is attractive to both manufacturers and consumers. In addition, partnerships between technology firms and healthcare organizations are strengthening research and development initiatives, resulting in improved product offerings. Finally, the global movement towards sustainability and environmentally friendly practices is generating interest in 3D printed wearables, as these innovations often employ sustainable materials and methods, making them an appealing option in the marketplace.

3D Printed Wearable Market Restaining Factors:

The primary obstacles facing the 3D printed wearable industry encompass elevated manufacturing expenses, restricted choices of materials, and regulatory hurdles.

The market for 3D printed wearables is confronted with numerous challenges that impede its growth trajectory. A primary obstacle is the substantial initial investment needed for cutting-edge 3D printing technologies, which often discourages small enterprises and startups from entering the sector. In addition, the absence of standardized materials and printing techniques can result in varying product quality, complicating efforts to establish consumer confidence. Regulatory challenges also represent a significant barrier, as the wearable technology sector must adhere to intricate health and safety regulations that differ across regions, potentially delaying product development and market launch. Furthermore, consumers' limited familiarity and skepticism regarding the durability and functionality of 3D printed wearables can hinder market growth. Traditional manufacturing processes introduce additional competition by providing more cost-effective alternatives, which further challenges the acceptance of 3D printed products. Nonetheless, advancements in technology and increasing consumer awareness are facilitating a shift towards adaptability within the market, opening avenues for innovation and greater sustainability. By focusing on educating consumers about the advantages of 3D printed wearables, there is potential for increased acceptance and accelerated market expansion in the future.

Segments of the 3D Printed Wearable Market

By Type

- Clothing

- Footwear

- Accessories

By Material Type

- Bio-based Materials

- Thermoplastics

- Metals

By Printing Technology

- Fused Deposition Modeling

- Selective Laser Sintering

- Multi-jet Modeling

By Application

- Healthcare

- Fashion

- Sports and Recreation

By Sales Channel

- Online Marketplaces

- Retail Stores

- Direct-to-Consumer

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America