3D Printed Prosthetics Market Analysis and Insights:

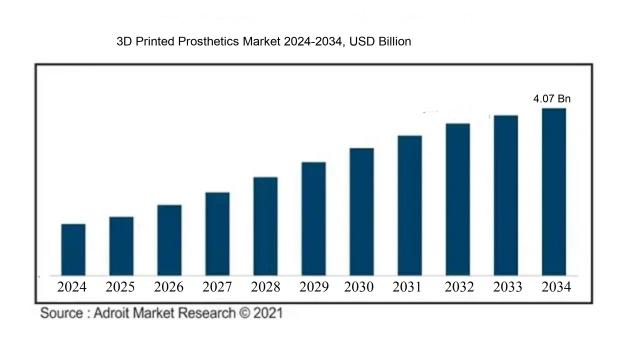

The size of the global market for 3D printed prostheses was USD 2.18 billion in 2024, increased to USD 2.95 billion in 2025, and is projected to reach around USD 4.07 billion by 2034, with a compound annual growth rate (CAGR) of 8.03% from 2024 to 2034.

The market for 3D printed prosthetics is experiencing growth due to several pivotal factors. Notably, advancements in additive manufacturing have facilitated the creation of personalized and economically viable prosthetic solutions tailored to individual requirements. The rising incidence of amputations linked to conditions such as diabetes, vascular diseases, and traumatic injuries has further stimulated the demand for innovative prosthetic devices. Additionally, enhanced awareness regarding the advantages of 3D printing—such as decreased production timelines and minimized material waste—has fostered greater acceptance of these technologies in the healthcare sector. Increased investment from both public and private entities aimed at bolstering research and development in prosthetics also supports market expansion. Furthermore, social dynamics, including a commitment to inclusivity and the pursuit of improved patient outcomes, have intensified the need for affordable and accessible prosthetic alternatives, further driving the growth of the 3D printed prosthetics market.

3D Printed Prosthetics Market Definition

3D-printed prosthetics are bespoke artificial limbs created using additive manufacturing methods, enabling designs that cater specifically to individual requirements. These groundbreaking devices provide improved comfort and usability, frequently at a lower price point than conventional prosthetics.

Three-dimensional printed prosthetics play a crucial role in transforming the landscape of assistive devices by enhancing accessibility, reducing costs, and allowing for personalized designs. Conventional prosthetic limbs typically require extensive production times and are often prohibitively expensive, making them out of reach for numerous individuals who need them. In contrast, 3D printing facilitates swift prototyping and modifications that cater specifically to the user’s distinct anatomical features, thereby improving both comfort and effectiveness. Additionally, recent advancements in materials and technologies lead to the creation of lighter, more resilient prosthetics that can be produced as needed. This breakthrough not only elevates the quality of life for those with limb loss but also promotes greater autonomy and social integration, marking a significant advancement in the field of medical technology.

3D Printed Prosthetics Market Segmental Analysis:

Insights On Type

Limbs

The limbs in the Global 3D Printed Prosthetics Market is expected to dominate due to increasing advancements in 3D printing technology, which allows for the customization of prosthetic limbs according to individual patient's needs. The recent trend of producing lighter, more functional, and aesthetically pleasing prosthetic limbs is attracting consumers and healthcare providers alike. Moreover, innovations in biomechanics are improving functionality and usability, which enhances the quality of life for amputees. This has seen a surge in attention and investment, leading to rapid advancements that are aligning well with the demands of the market, thus solidifying its position as the leader.

Sockets

Sockets are a crucial component of prosthetic devices, providing the necessary interface between the residual limb and the prosthetic limb. Advances in 3D printing technology have enabled the creation of custom-fitted sockets that enhance comfort and fit for users. Customization in socket design accommodates a variety of limb shapes and sizes, thereby reducing discomfort. However, while they are critical for a successful prosthetic application, they are often viewed as a supportive, rather than leading, component in the overall design of prosthetics.

Joints

The joints category is essential for the functionality of prosthetic limbs, enabling movement and articulation. Advances in 3D printing allow for the creation of more complex and functional joints, which are increasingly being designed to mimic the natural movement of human joints. However, the adoption in this tends to lag behind limbs due to cost considerations and the technical challenges involved in creating highly functional, durable joints. This limits their market share compared to more recognized s like limbs.

Others

The "Others" category can include various components and innovations within the prosthetic market, such as cosmetic covers and specialized attachments. While these offerings hold value for personalization and enhancement of prosthetic devices, they represent a smaller of the overall market. Innovative approaches within this space could potentially gain traction, but they currently do not command significant market share compared to limbs, sockets, and joints, limiting their overall impact on market dynamics.

Insights On Material

Polypropylene

Polypropylene is projected to dominate the Global 3D Printed Prosthetics Market due to its exceptional strength-to-weight ratio, flexibility, and biocompatibility. As the demand for lightweight and durable prosthetics increases, polypropylene offers a cost-effective solution suitable for various applications. Its resistance to fatigue and chemical exposure enhances its appeal in prosthetic manufacturing, as it can withstand everyday wear and tear. Furthermore, polypropylene is highly recyclable, catering to the growing emphasis on sustainability in the healthcare sector. This material aligns well with the continuous innovation in 3D printing technologies, making it a preferred choice among manufacturers for producing advanced prosthetic devices.

Polyethylene

Polyethylene has gained traction in the 3D Printed Prosthetics Market owing to its high impact resistance and ease of fabrication. This material is particularly beneficial for creating prosthetic components that require a good balance between flexibility and strength. Its lighter weight aids the comfort and mobility of the wearer, making it an appealing option for users who prioritize ease of use. Additionally, polyethylene can be produced in various densities, allowing for customization according to specific needs in the prosthetic design.

Acrylics

Acrylics are being increasingly utilized in the development of 3D printed prosthetics for decorative and functional parts due to their exceptional clarity and aesthetic appeal. They offer improved transparency and can be easily colored or finished, allowing for personalized designs that align with the preferences of individual users. Acrylics exhibit good UV resistance and are highly adaptable in terms of processing techniques, making them suitable for intricate shapes and details in prosthetic applications. However, their mechanical properties may limit their usage in load-bearing components.

Polyurethane

Polyurethane is favored in the 3D Printed Prosthetics Market for its outstanding elasticity and resilience, making it ideal for creating softer prosthetic components that provide comfort and cushioning. This material can be formulated to achieve various degrees of hardness, presenting extensive possibilities for bespoke solutions. Polyurethane's excellent abrasion resistance helps in maintaining the integrity of the prosthetic over time. However, it may face limitations in terms of long-term stability compared to other materials, which could affect its overall adoption in more permanent fixtures.

Insights On End-use

Hospitals

The hospitals sector is expected to dominate the Global 3D Printed Prosthetics Market mainly due to their capacity to integrate advanced technologies and comprehensive resources for patient care. Hospitals have larger patient volumes and the ability to invest in innovative manufacturing methods, making them ideal for utilizing 3D printed prosthetics. Furthermore, hospitals are equipped with multidisciplinary teams, including orthopedic surgeons, rehabilitation specialists, and advanced technology experts, enabling seamless adaptation of 3D printed solutions tailored to individual patient needs. This cohesive approach not only enhances patient outcomes but also drives efficiency in production and distribution processes, positioning hospitals as the leading in the market.

Rehabilitation Centers

Rehabilitation centers play a crucial role in the recovery process following limb loss or trauma. These facilities focus on helping patients regain mobility and functionality through personalized rehabilitation programs. While the center's impact on the adoption of 3D printed prosthetics is significant, it predominantly serves as an extension of hospital care, focusing on physical therapy and adjustment of the prosthetics over time. Their contribution is vital, but it is often supplemental to the primary care provided by hospitals, limiting their dominance in the market.

Prosthetic Clinics

Prosthetic clinics are specialized entities focused on the design and fitting of prosthetics. They cater to niche needs of patients requiring custom prosthetic solutions and may utilize 3D printing technology to create tailored products. However, their reach is generally limited compared to hospitals, as they operate on a smaller scale and often rely on hospital referrals. The specialized nature of prosthetic clinics means they are essential for post-operative care and adjustments but do not significantly drive the overall demand for 3D printed prosthetics on a market-wide scale.

Global 3D Printed Prosthetics Market Regional Insights:

North America

North America is expected to dominate the Global 3D Printed Prosthetics market due to several key factors. The region boasts advanced healthcare infrastructure, significant investments in research and development, and a high adoption rate of cutting-edge technologies. Additionally, the presence of leading medical device manufacturers and progressive regulatory frameworks facilitate innovation in the prosthetics market. The growing prevalence of limb loss, driven by factors such as accidents and diabetic complications, further fuels demand for customized and efficient 3D printed prosthetics solutions. As a result, the confluence of technological advancements, healthcare accessibility, and market readiness positions North America as the leading region in this sector.

Europe

Europe represents a vibrant market for 3D printed prosthetics, characterized by a strong emphasis on innovation and sustainability. European countries prioritize advanced healthcare systems and have regulatory bodies that foster the adoption of novel medical technologies. The increasing focus on personalized medicine, along with initiatives aimed at enhancing rehabilitation methods for amputees, contributes to market growth. The collaborative efforts among academic institutions, research organizations, and healthcare providers in Europe also drive advancements in this field, although fierce competition and varying regulations across countries can create challenges.

Asia Pacific

The Asia Pacific region is witnessing rapid growth in the 3D printed prosthetics market, propelled by increasing urbanization, rising disposable incomes, and improving healthcare facilities. Countries like China, India, and Japan are investing in advanced manufacturing technologies and innovations in medical devices. A large population base, coupled with a growing awareness of prosthetic solutions, suggests significant unmet needs. However, challenges such as regulatory hurdles and disparities in healthcare access among nations may impact the pace of growth in certain areas across the region.

Latin America

Latin America is showing potential in the 3D printed prosthetics market, driven by an increasing incidence of chronic diseases and traumatic injuries that necessitate prosthetic solutions. The region benefits from scattered but promising investment in healthcare and technology. However, challenges such as economic instability and inconsistent healthcare quality can hinder the widespread adoption of 3D printed prosthetics. Efforts to enhance healthcare access and affordability could help propel this market forward, but significant work remains to establish robust infrastructure for widespread distribution and usage.

Middle East & Africa

The Middle East & Africa region exhibits a nascent market for 3D printed prosthetics, reflecting a growing awareness and demand for modern medical solutions. Countries in this region are increasingly investing in healthcare improvements and technological advancements. However, challenges such as limited healthcare infrastructure and socioeconomic factors may impede market growth. As awareness increases about the benefits of 3D printing in prosthetics, there is potential for growth, particularly in urban areas. Focused investments in healthcare infrastructure and partnerships with global prosthetics manufacturers could improve prospects in the coming years.

3D Printed Prosthetics Competitive Landscape:

Major contributors in the worldwide market for 3D printed prosthetics are fueling innovation through the advancement of cutting-edge printing techniques and materials, which improve the degree of customization and availability for users. They work in partnership with healthcare professionals to guarantee that prosthetic offerings align with changing medical requirements and comply with regulatory guidelines.

Prominent entities within the 3D printed prosthetics sector comprise Össur, Materialise, 3D Systems, Stratasys, Adaptive 3D, Artec 3D, VIVO Healthcare, NextStep 3D, e-NABLE, and Fillauer LLC. Furthermore, organizations such as Stryker, Prosthetics and Orthotics International, Anatomics, Renishaw, and Aon3D also play significant roles in this field. These companies are acknowledged for their groundbreaking innovations and progress in 3D printing technologies focused on improving the design and manufacturing of prosthetic devices.

Global 3D Printed Prosthetics COVID-19 Impact and Market Status:

The Covid-19 pandemic significantly expedited the incorporation of 3D printed prosthetics, underscoring the crucial role of rapid prototyping and personalized solutions in the healthcare sector amid challenges in supply chain logistics.

The COVID-19 pandemic had a profound effect on the market for 3D-printed prosthetics, bringing to the forefront both obstacles and potential for growth within the sector. Initially, the implementation of lockdowns caused significant interruptions in supply chains and production procedures, resulting in delays for prosthetic device manufacture and distribution. Conversely, this situation also propelled the rapid integration of 3D printing technologies as healthcare providers sought creative approaches to address the increasing need for tailored and affordable prosthetics. The ened emphasis on remote healthcare and telemedicine fostered the creation of more versatile and user-friendly devices, improving accessibility for patients. Furthermore, the swift advancements in materials and manufacturing techniques stimulated by the pandemic led to notable enhancements in the customization of prosthetics, thereby increasing their comfort and functionality. In summary, the market is expected to recover and expand as it adjusts to these transformed circumstances, focusing more on resilience, efficiency, and solutions that prioritize patient needs in the design and production of prosthetics.

Latest Trends and Innovation in The Global 3D Printed Prosthetics Market:

- In May 2021, E-nabling The Future, a global network of volunteers, launched a program to provide free, 3D-printed prosthetic hands for children, showcasing advancements in community-driven prosthetic production.

- In March 2022, Össur announced the acquisition of solid thinking, a company specializing in 3D printing technology, enhancing its capabilities in creating custom prosthetic devices tailored to patients' needs.

- In April 2022, the startup Limbitless Solutions unveiled a newly designed 3D-printed prosthetic arm aimed at low-cost production, incorporating innovative materials and designs to improve user experience and accessibility.

- In August 2022, Materialise N.V. expanded its 3D printing software solutions with new features specifically aimed at the prosthetics market, improving design efficiency and production timelines for healthcare providers.

- In September 2022, Stratasys launched a collaboration with the nonprofit organization, e-NABLE, to provide advanced 3D printing technology and resources for creating prosthetics in underserved communities.

- In January 2023, 3D Systems introduced a new method for producing flexible prosthetic sockets with its Figure 4 technology, allowing for faster production times and improved comfort for users.

- In June 2023, OdontoMed2020 announced a partnership with local hospitals in Mexico to produce 3D-printed prosthetics as part of a pilot program, focusing on affordability and customization for patients.

- In July 2023, Bionics announced it had developed a next-generation prosthetic limb utilizing AI and 3D printing, offering enhanced functionality and integration with user movements for improved performance and adaptability.

- In August 2023, the nonprofit organization, Enable the Future, revealed an upgrade to its online platform enabling faster and more efficient design sharing of 3D printed prosthetics, allowing for easier access for developers and families.

3D Printed Prosthetics Market Growth Factors:

The expansion of the market for 3D-printed prosthetics is fueled by technological advancements, a rising need for personalized solutions, and improved cost-effectiveness in comparison to conventional prosthetic alternatives.

The market for 3D printed prosthetics is witnessing remarkable expansion, propelled by several pivotal elements. Initially, innovations in 3D printing techniques, encompassing improved materials and methodologies, are enabling the creation of high-quality, personalized prosthetic devices tailored to the unique needs of individual patients. The decreased manufacturing expenses associated with 3D printing are making these solutions more affordable, thus broadening access for a larger demographic. Moreover, the rising incidence of chronic illnesses, accidents, and conditions that lead to limb loss is driving the demand for prosthetic solutions upward.

The shift towards patient-centered healthcare and personalized medicine further emphasizes the importance of bespoke designs that improve both comfort and functionality, which in turn accelerates market growth. In addition, partnerships between healthcare providers and technology firms are spurring innovative breakthroughs in biocompatible materials, significantly enhancing the durability and visual appeal of prosthetics.

Increasing awareness among patients and healthcare professionals regarding advanced prosthetic options is also playing a crucial role in driving adoption rates. Lastly, supportive government initiatives and funding directed towards biotechnology research are fostering the growth of the 3D printed prosthetics sector by encouraging innovation and enhancing accessibility in healthcare. Collectively, these dynamics are setting the stage for a strong growth trajectory in this market.

3D Printed Prosthetics Market Restaining Factors:

The market for 3D-printed prosthetics encounters various obstacles, including elevated manufacturing expenses, regulatory complexities, and a lack of awareness among medical professionals.

The market for 3D printed prosthetics encounters numerous obstacles that may impede its expansion. A primary concern is the steep initial investment required for both the 3D printing technology and the materials, which can restrict access for smaller medical facilities and individuals in economically disadvantaged areas. Furthermore, the complex and often lengthy regulatory processes associated with medical devices necessitate comprehensive testing and approvals, potentially delaying the integration of novel designs into practice. Additionally, there exists a widespread lack of awareness regarding the advantages and capabilities of 3D printed prosthetics among healthcare professionals and patients alike, which could result in their underuse. The rapid pace of technological evolution also presents a challenge; manufacturers may find it difficult to adapt quickly without straining their resources. Moreover, the concerns surrounding the durability of materials and their long-term effectiveness indicate a need for further research and development. Nonetheless, the outlook for the 3D printed prosthetics industry is optimistic, fueled by continuous technological progress, an increasing variety of customization options, and ened awareness among healthcare entities, all of which strive to enhance patient care and improve the quality of life for those with limb loss.

Key Segments of the 3D Printed Prosthetics Market

By Type :

- Sockets

- Limbs

- Joints

- Others

By Material :

- Polyethylene

- Polypropylene

- Acrylics

- Polyurethane

By End-use :

- Hospitals

- Rehabilitation Centers

- Prosthetic Clinics

Regional Overview

North America

- US

- Canada

- Mexico

Europe

- Germany

- France

- U.K

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

Middle East and Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

Latin America

- Brazil

- Argentina

- Rest of Latin America